Device and method for preparing hard carbide ceramic coating based on composite treatment of large-area high-current pulsed electron beam

A high-current pulse, composite treatment technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of coating damage, can not be treated with ceramic coating, etc., to avoid coating oxidation, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

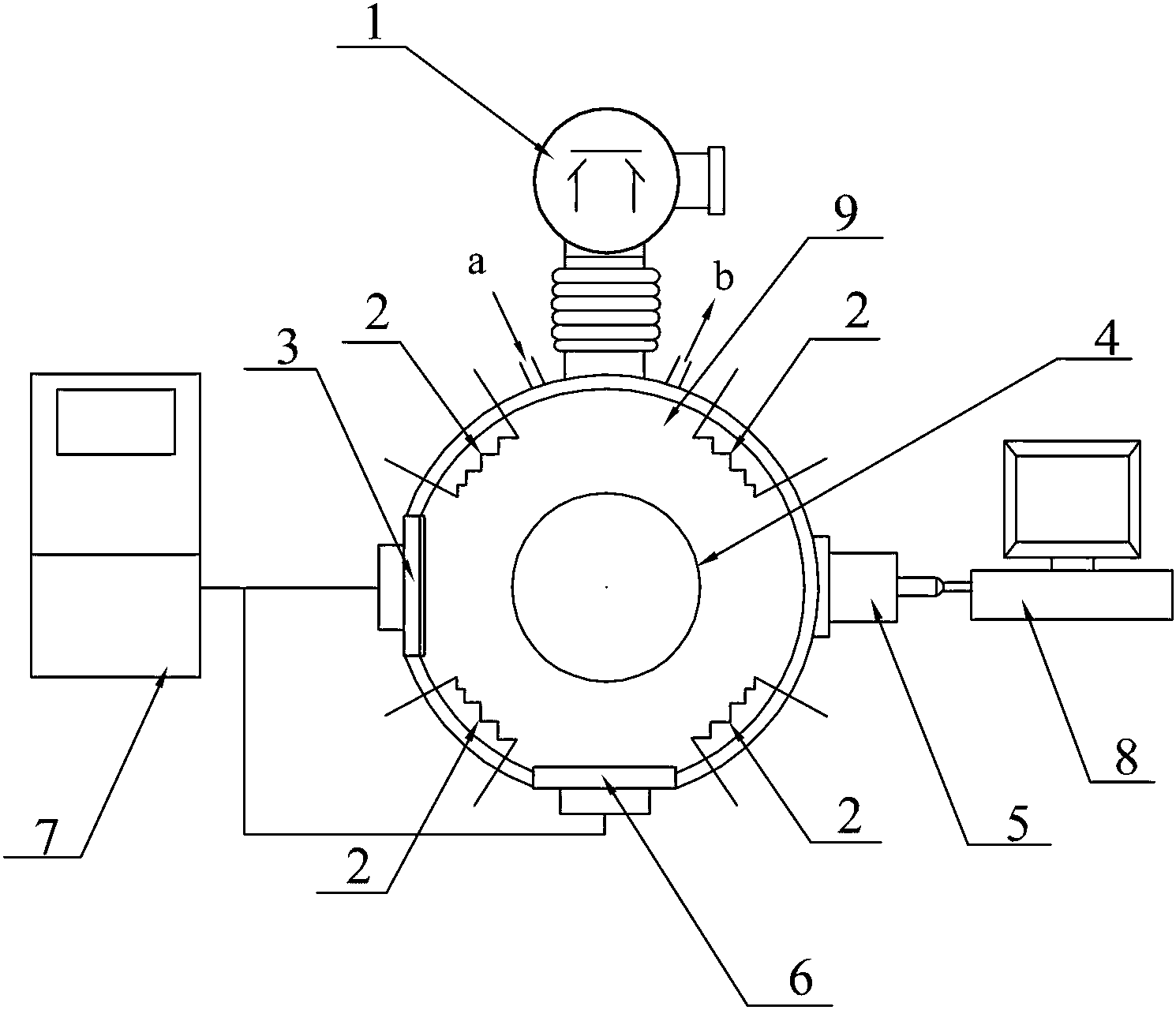

[0024] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the device for preparing hard carbide ceramic coatings based on large-area high-current pulsed electron beam composite treatment described in this embodiment is characterized in that it includes: a vacuum pump group 1, four heaters 2, graphite Target 3, rotating sample stage 4, electron gun 5, metal target 6, coating control power supply 7, computer 8 and vacuum chamber 9;

[0025] The air inlet of the vacuum pump group 1 communicates with the inner chamber of the vacuum chamber 9 through a vacuum tube; The water inlet a and a water outlet b, the water inlet a and the water outlet b communicate with the inner space between the double walls, the water inlet a is used to inject cold water into the middle of the double wall of the vacuum chamber 9, and the water outlet b is used for To discharge the water, cool the temperature in the vacuum chamber 9; a rotating sample stage 4 i...

specific Embodiment approach 2

[0031] Specific implementation mode two: the following combination figure 1 Describe this embodiment. This embodiment is a further description of Embodiment 1. The four heaters 2 described in this embodiment are respectively located in the middle of the vacuum pump group 1 and the graphite target 3, in the middle of the graphite target 3 and the metal target 6, The middle of the metal target 6 and the electron gun 5, the middle of the electron gun 5 and the vacuum pump group 1.

specific Embodiment approach 3

[0032] Specific implementation mode three: the following combination figure 1 This embodiment is described. This embodiment is a further description of Embodiment 1. The water inlet a and the water outlet b described in this embodiment are respectively arranged on both sides of the vacuum tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com