A method for preparing metal matrix composite coating on stainless steel surface

A metal composite, stainless steel technology, applied in the surface reaction electrolytic coating, metal material coating process, coating and other directions, can solve the problems of reducing the high temperature friction and wear performance of the coating, uneven oxide layer, oxide layer peeling, etc. The effect of improving surface roughness, enhancing mechanical properties, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The following examples are only preferred technical solutions of the present invention, and are not intended to limit the present invention. Various modifications and variations of the present invention are possible for those skilled in the art. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included within the protection scope of the present invention.

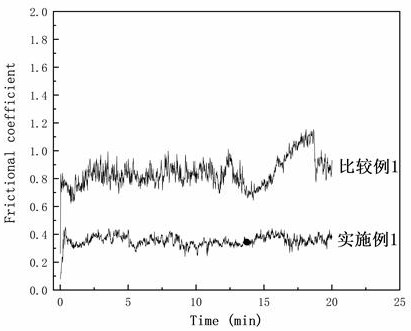

[0041] Example 1

[0042] Grind the 304 stainless steel substrate with 180#, 500#, and 1000# sandpaper in turn to obtain 304 stainless steel with a smooth surface, and then put the 304 stainless steel substrate in a muffle furnace to preheat to 600 ℃ and keep it for 1h to reduce the damage caused by the substrate and the Coating cracking due to stress caused by differences in thermal expansion between coating materials.

[0043] The TiBCN powder was dried in a vacuum drying oven at 80 °C for 1 h and kept for 12 h to obtain

[0044] P...

Embodiment 2

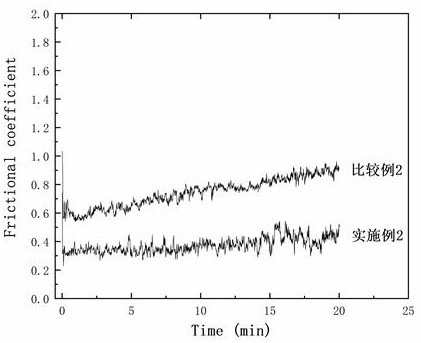

[0056] Grind the 304 stainless steel substrate with 180#, 500# and 1000# sandpaper in turn to obtain 304 stainless steel with a smooth surface, and then put the 304 stainless steel substrate in a muffle furnace to preheat to 600 ° C, and keep it for 1h to reduce the damage caused by the substrate and the Coating cracking due to stress caused by differences in thermal expansion between coating materials.

[0057] The TiBCN powder was dried in a vacuum drying oven at 100 °C for 1 h and kept for 12 h to obtain a powder with better fluidity.

[0058] Using laser cladding technology, the above TiBCN powder is put into the powder feeding tank, and argon gas is used as the carrier gas to carry the TiBCN powder to the laser nozzle. The laser power is 1400W and the scanning speed is 5mm / s, the powder feeding rate is 280mg / s.

[0059] Polish the prepared laser cladding coating with 180#, 500#, and 1000# sandpaper on a polishing machine to remove the surface oxide layer and unmelted pa...

Embodiment 3

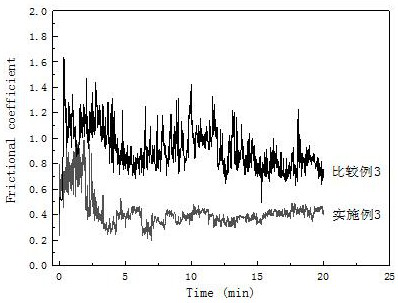

[0068] Grind the 304 stainless steel substrate with 180#, 500# and 1000# sandpaper in turn to obtain 304 stainless steel with a smooth surface, and then put the 304 stainless steel substrate in a muffle furnace to preheat to 600 ° C, and keep it for 1h to reduce the damage caused by the substrate and the Coating cracking due to stress caused by differences in thermal expansion between coating materials.

[0069] The TiBCN powder was dried in a vacuum drying oven at 120 °C for 1 h and kept for 12 h to obtain

[0070] Powder with better flow.

[0071] Using laser cladding technology, the above TiBCN powder is put into the powder feeding tank, and argon is used as the carrier gas to carry the TiBCN powder to the laser nozzle. The laser power is 1300W and the scanning speed is 6mm / s, the powder feeding rate is 250mg / s.

[0072] Polish the prepared laser cladding coating with 180#, 500#, and 1000# sandpaper on a polishing machine to remove the surface oxide layer and unmelted pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com