Integrated circuit analysis system and method with partially evacuated volume for electron beam manipulation

An integrated circuit, electron beam technology, applied in the field of integrated circuit analysis systems and methods with a local evacuation volume for electron beam operation, can solve problems such as slowness, cumbersomeness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

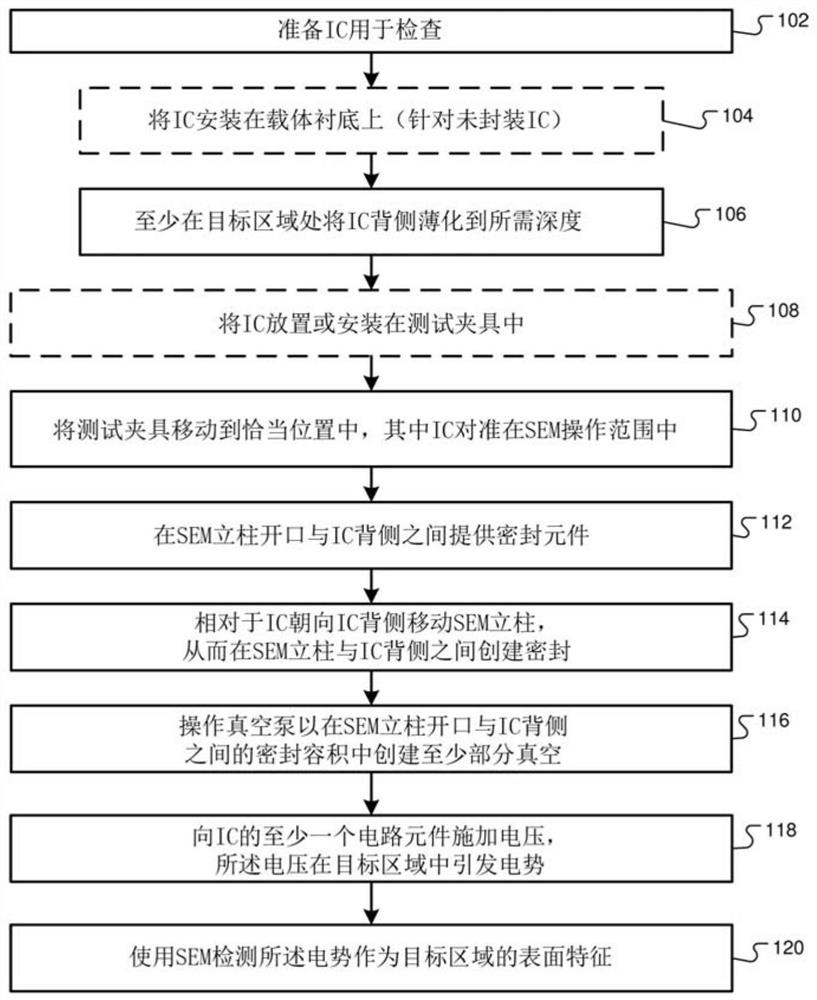

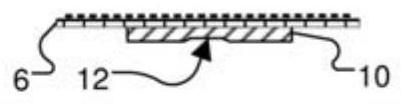

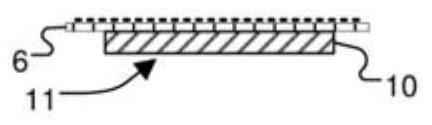

[0021] The present invention describes a new method for failure analysis in IC semiconductor devices. Several system designs and methods are provided to achieve a device under test (DUT) while it is being electrically stimulated by an automated test equipment (ATE) tester or while the device is on its own or mounted in a circuit board or other module. Electron beam (e-beam) technology is used to probe the transistors contained within the IC DUT, its dopant wells and their auxiliary connections while active within the host system. The DUT may be a packaged IC, or it may exist in unpackaged form, including as part of an overall fabricated wafer. Existing electron beam probing systems require the DUT to be placed in a high vacuum environment. The designs and methods herein seek to avoid the need to place the DUT in a high vacuum and instead use an environmental scanning electron microscope (ESEM) or a low vacuum SEM, where the DUT can be in a relatively low ("bad") vacuum enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com