Electron beam paint quick-drying device and using method thereof

An electron beam and electron beam source technology, applied in the field of electron beams, can solve the problems of poor durability and low paint curing efficiency, and achieve the effects of flexible layout, small footprint and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

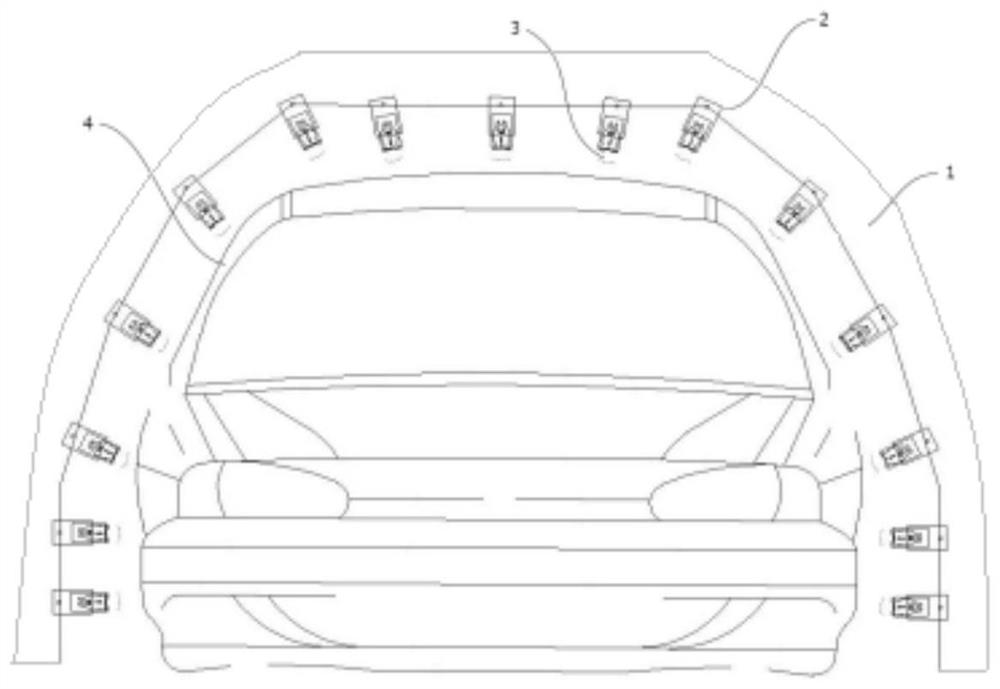

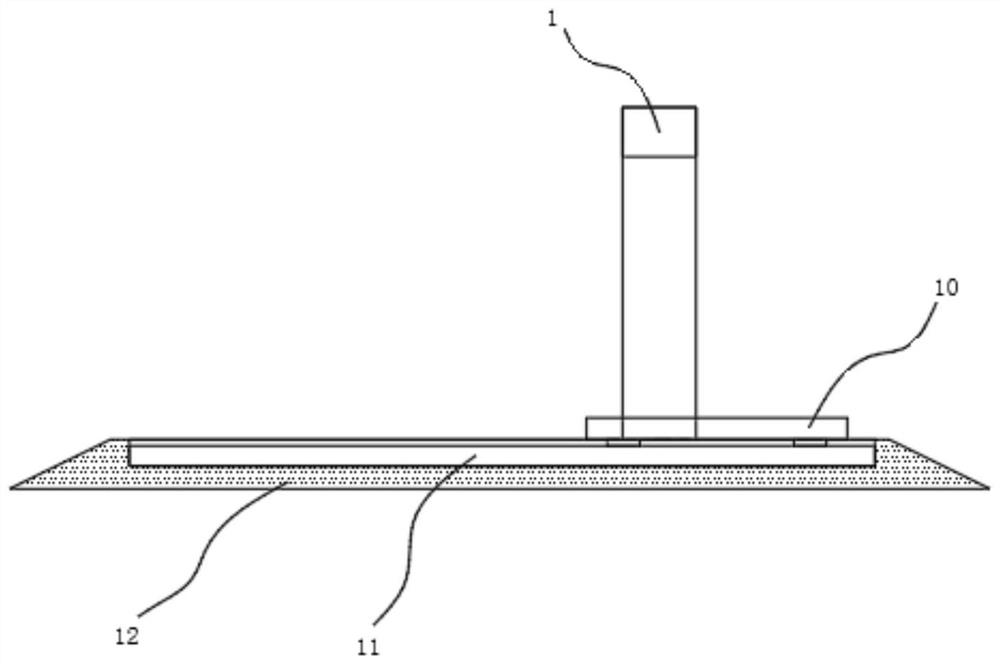

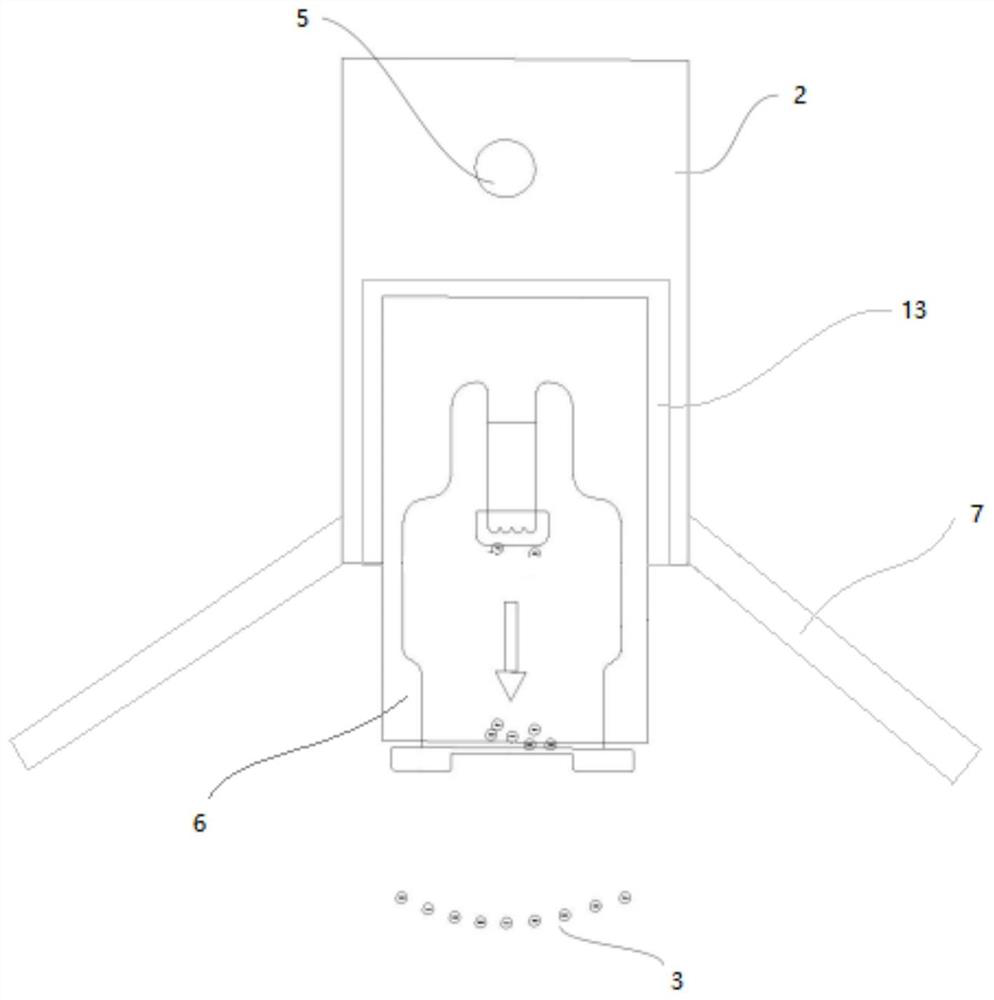

[0030] refer to Figure 1-4 , an electron beam paint quick-drying device, comprising a support base 12, one end of the support base 12 is fixedly provided with a gantry support 1, the inner wall of the gantry support 1 is provided with a number of installation grooves arranged at equal distances, and the inner walls of the installation grooves are provided with The casing 2 is installed, the inner wall of the gantry bracket 1 is provided with a car shell 4 , and the inner wall of the adjacent end of the installation casing 2 is provided with an electron beam source 6 , and the electron beam source 6 reflects the electron beam 3 .

[0031] In the present invention, a sleeve 13 is fixedly installed on the inner wall of the bottom of the installation casing 2 , and the inner wall of the sleeve 13 is slidably arranged with the outer wall of the electron beam source 6 , and a stepping device 14 is arranged between the inner wall of the sleeve 13 and the electron beam source 6 . , a...

Embodiment 2

[0043] refer to Figure 1-4 , an electron beam paint quick-drying device, the car shell 4 is electrically connected with a bias generator, and a positive bias voltage of 500-4000V is applied to the surface of the car shell 4, so that the electron beam 3 is better aligned with the paint surface, reaching Better curing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com