Electron beam thermosetting resin 3D printing and application thereof

A thermosetting resin and 3D printing technology, which is applied in the direction of 3D object support structure, additive manufacturing, and accessories for processing main materials, etc., can solve problems that cannot be applied to thermosetting molding of resin materials, cannot realize high-end product processing, and cannot achieve nanometer precision 3D printing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

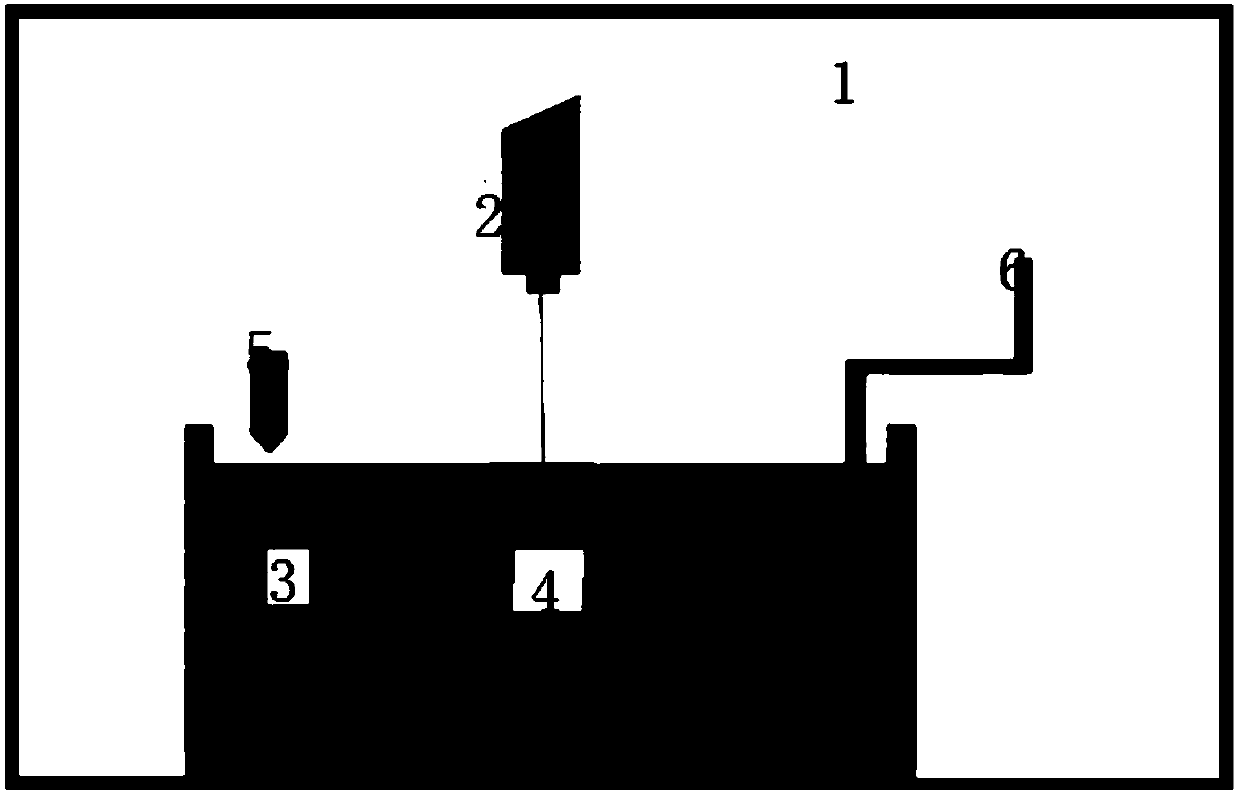

[0027] A 3D printing system for electron beam thermosetting resin with a complete structure, the beam spot diameter of the electron beam source is 50 microns, the power is 100W, and the electron beam energy is 30keV; the electron beam source is fixed on a 5-axis workbench. The beam can be moved back and forth, left and right, and tilted; the 5-axis workbench is connected to the computer system, and the printed product is processed by computer graphics to output the graphics required for each layer of printing, and to control the displacement and tilt of the electron beam source to achieve different beam alignments. position of the resin for curing.

[0028] The resin liquid tank is located below the electron beam source. The resin liquid tank is a stainless steel cube structure with a size of 100mmX100mmX100mm. The product printing workbench is inside the resin liquid tank with an area size of 50mmX50mm. The displacement of the product workbench is driven by the lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com