Light polyurethane plastic rubber paving material

A polyurethane and plastic technology, applied in the field of new lightweight polyurethane pavement materials, can solve the problems of reduced fluidity and achieve the effects of small dry shrinkage, cost reduction and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] According to the following formula respectively, the unit of each component is Kg, to produce component A, component B and composite catalyst, that is to say, mix according to the conventional method respectively.

[0049] A component B component Composite catalyst

[0050] TDI: 35 MOCA: 50 Lead isooctanoate: 61.2

[0051] N-2028: 65 Fly ash: 350 Zinc isooctanoate: 38.8

[0052] Clay: 100

[0053] White carbon black: 5

[0054] N-330: 67

[0055] DOP: 400

[0056] Iron oxide red: 26

[0057] UV-531: 0.5

[0058] 1010:2.6

[0059] Antifungal agent: 1.3

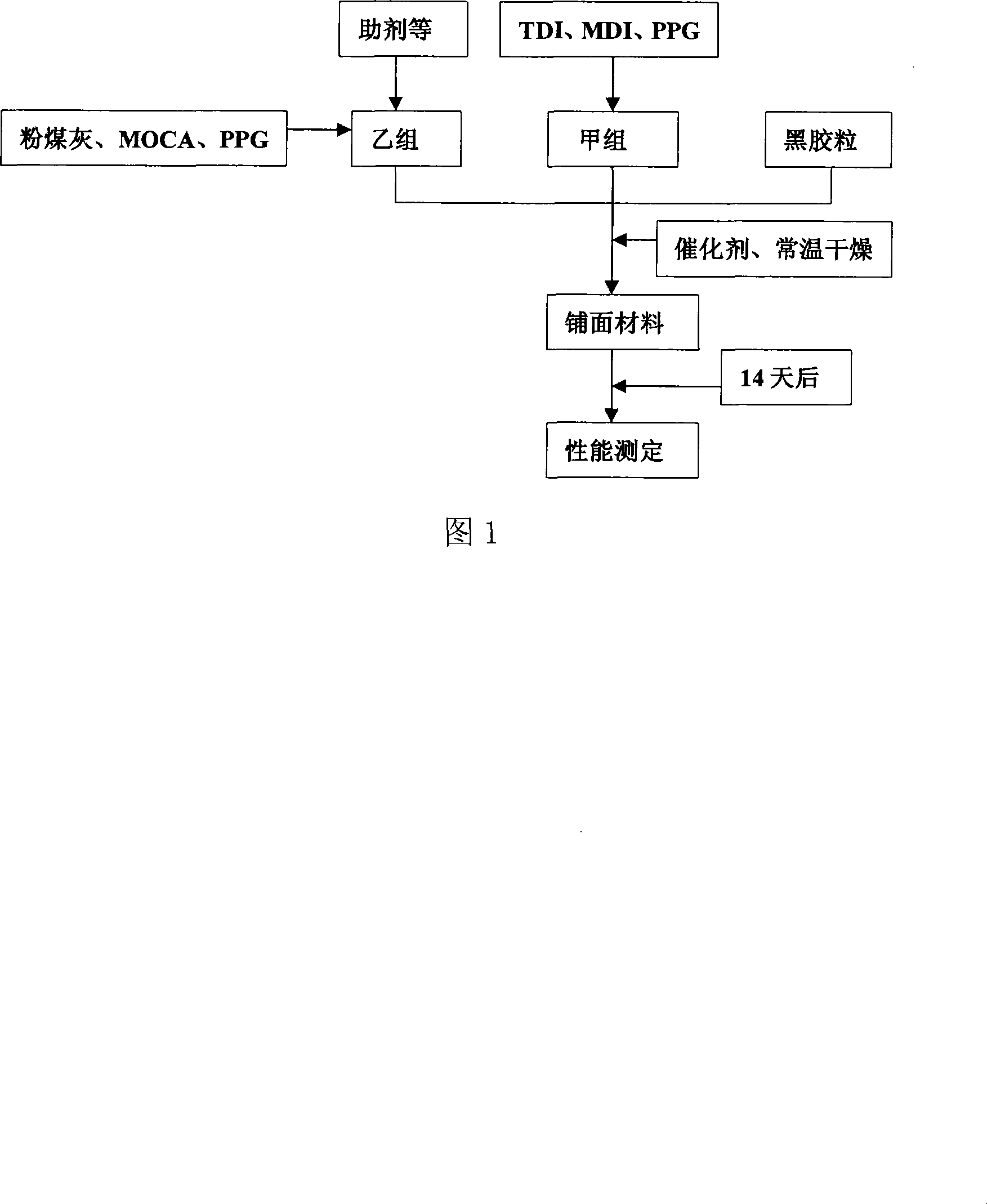

[0060] During on-site construction, mix components A and B according to the ratio of 1:2-6, then add 10-30% of the total weight of black colloidal particles, add 1%-6% of the weight of group A composite catalyst and mix After uniformity, pave the lower layer, see the schematic diagram of the pr...

Embodiment 2

[0062] According to the following formula respectively, the unit of each component is Kg, to produce component A, component B and composite catalyst.

[0063] A component B component Composite catalyst

[0064] TDI: 29 MOCA: 48 Lead isooctanoate: 65

[0065] N-240: 71 Fly ash: 450 Zinc isooctanoate: 35

[0066] Clay: 100

[0067] White carbon black: 5

[0068] N-330: 66.6

[0069] Chlorinated paraffin: 400

[0070] Iron oxide red: 26

[0071] 1010:2.6

[0072] UV-531: 0.5

[0073] Antifungal agent: 1.3

[0074] During on-site construction, mix components A and B in a ratio of 1:2 to 6, add 1% to 6% of the weight of group A and mix evenly, and then pave the lower layer; mix components A and B according to 1 : Mix in a ratio of 2 to 6, add 1% to 6% of the weight of group A composite catalyst and mix evenly, pave the upper layer, spray the anti-slip layer, and dry.

Embodiment 3

[0076] According to the following formula respectively, the unit of each component is Kg, to produce component A, component B and composite catalyst.

[0077] A component B component Composite catalyst

[0078] MDI: 20 MOCA: 10 Lead naphthenate: 70

[0079] N-3035 and N-210: 80 Fly Ash: 400 Zinc Naphthenate: 30

[0080] Clay: 95

[0081] White carbon black: 5

[0082] N-330: 50

[0083] Stearic acid: 300

[0084] Fast Yellow: 1

[0085] 1010:50

[0086] UV-9: 50

[0087] Antifungal agent: 39

[0088]During on-site construction, mix components A and B in a ratio of 1:2 to 6, add 1% to 6% of the weight of group A and mix evenly, and then pave the lower layer; mix components A and B according to 1 : Mix in a ratio of 2 to 6, add 1% to 6% of the weight of group A composite catalyst and mix evenly, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com