Pressure sensor comprising an elastic sensor layer with a microstructured surface

A pressure sensor and sensing layer technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of the same magnitude shift of the response threshold, difficult to test sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

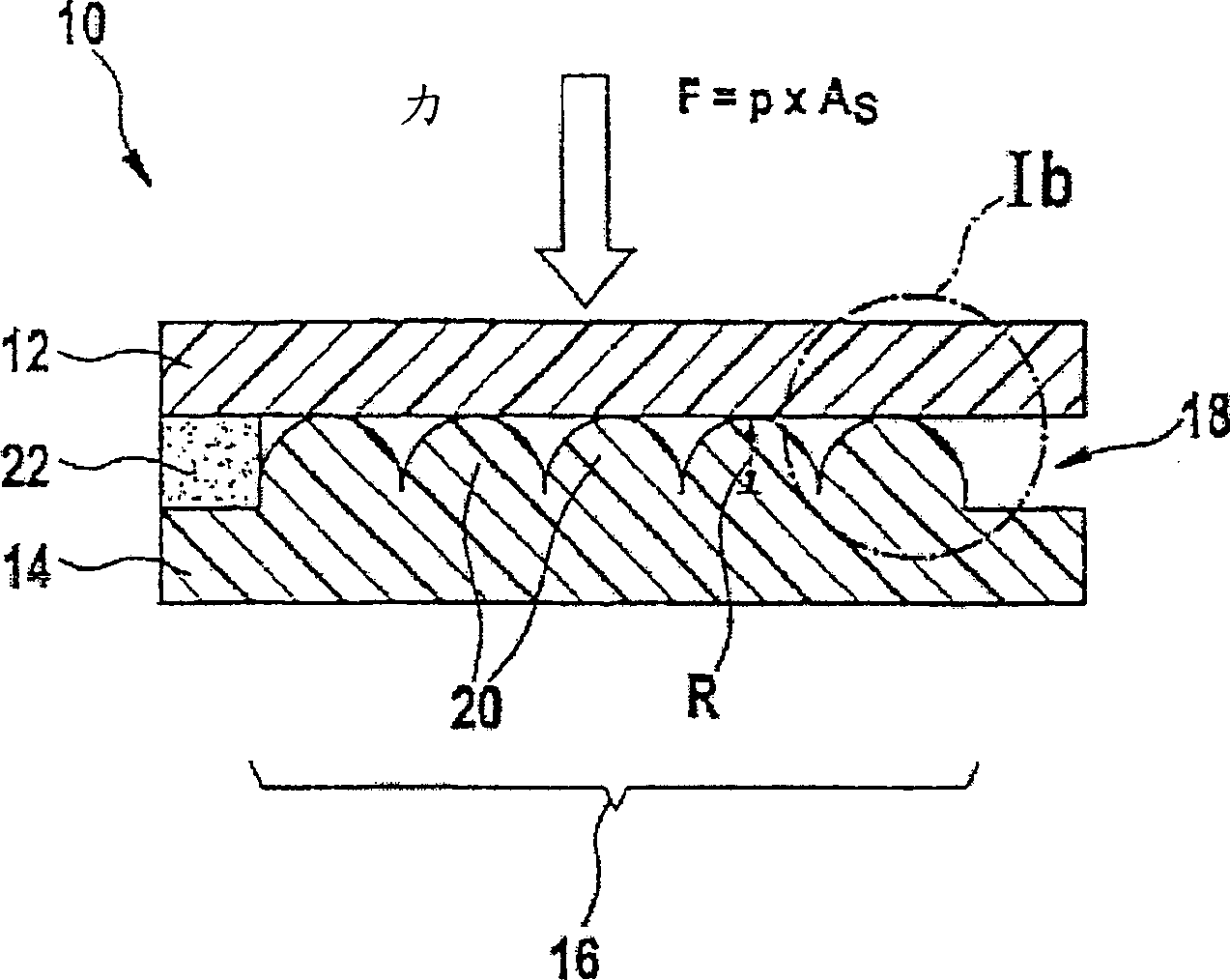

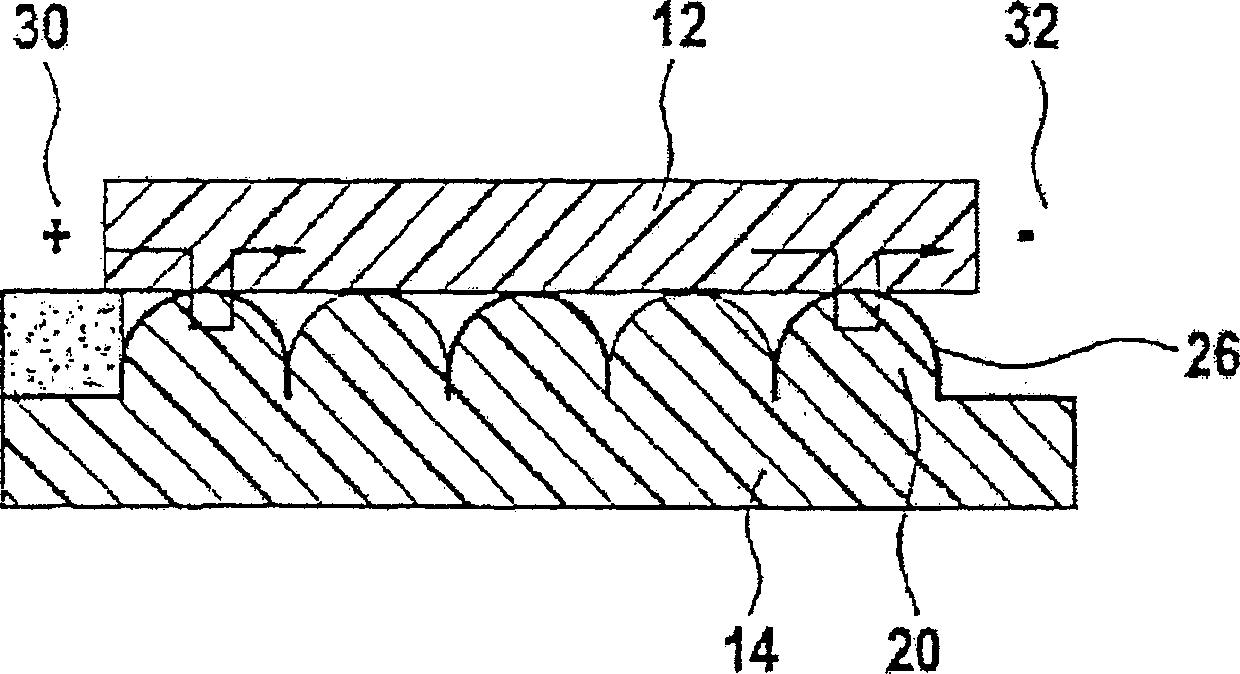

[0030] The present invention relates to pressure sensors based on elastic-mechanical deformation of microstructured surfaces. Figure 1a The structure of such a pressure sensor 10 is schematically shown. The sensor 10 basically comprises a first sensing layer 12 and a second sensing layer 14 of elastic and resistive material, each typically coated on a carrier foil (polymer foil) (not shown). Sensing layers 12 and 14 are arranged opposite each other so that a contact area is formed between them in active area 16 of pressure sensor 10 .

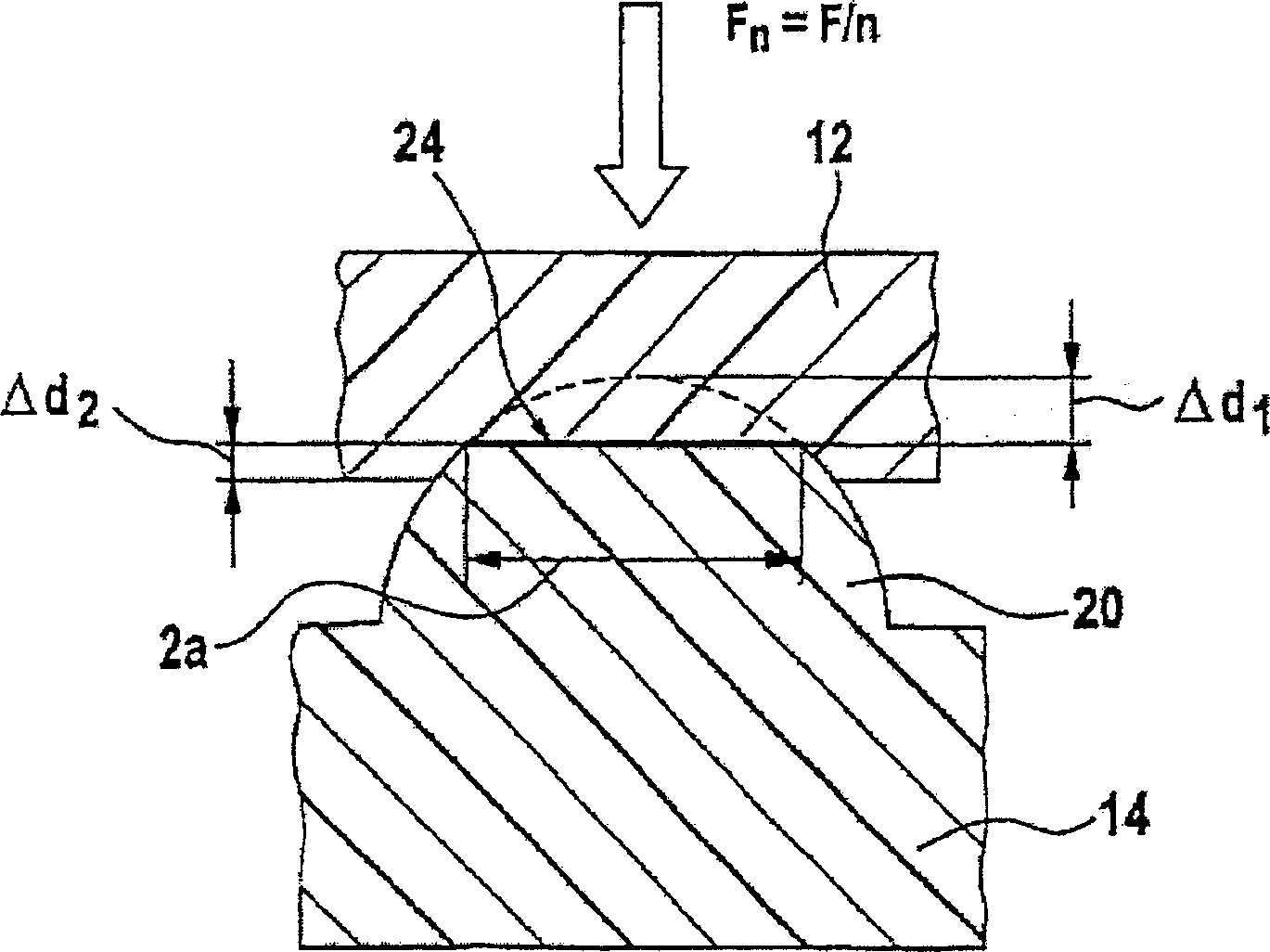

[0031] The second sensing layer 14 has a microstructured surface 18 in the region of the active region 16 of the pressure sensor 10 , which has a predetermined structure 20 of elastic material formed therein. Figure 1a A typical embodiment of such a pressure-sensitive microstructure 18 is shown. To this end, the second sensing layer 14 comprises a clearly defined topography in the active area 16 , which takes the form of a spherical structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com