Filed-effect tube channel type field emission cathode and preparation method thereof

A tube-channel type, field emission technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of difficult control of stability, and achieve the effect of uniform and stable field emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

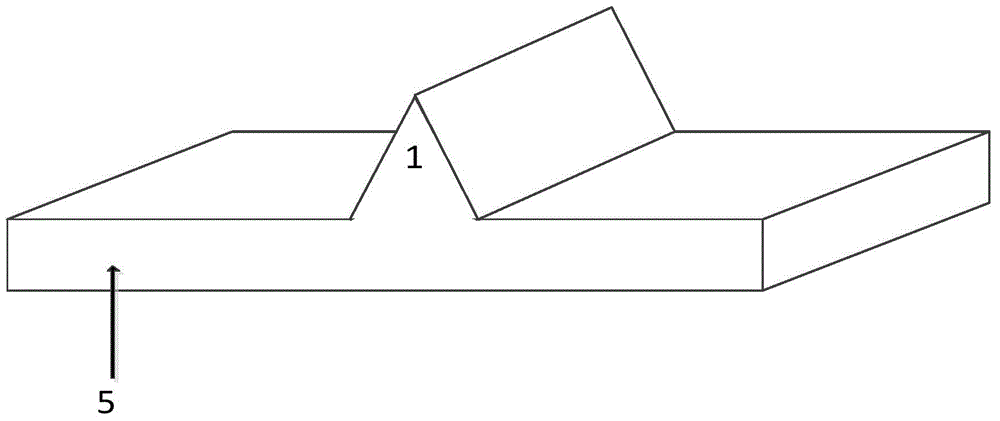

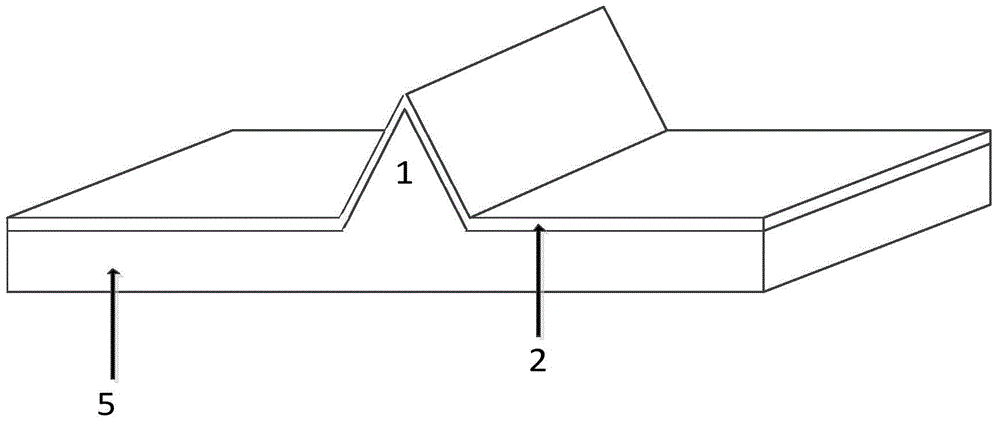

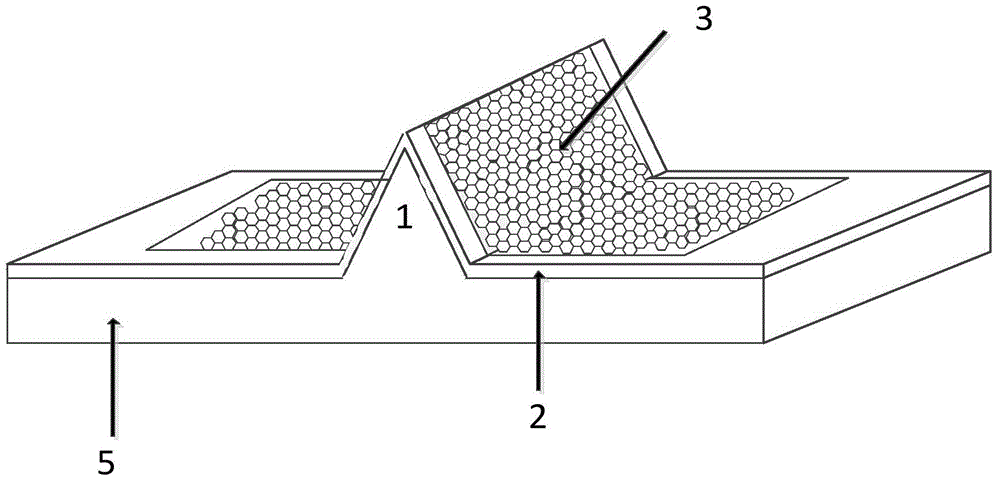

[0027] 1) A one-dimensional nano-edge is etched on the substrate. This solution uses Si-SiO 2 as a substrate. Firstly, in highly doped Si-SiO 2 A 2um-wide strip mask pattern is photo-etched on the wafer, and the SiO unprotected by the photoresist is etched using an HF etching solution. 2 layer, and the SiO was observed under the microscope 2 Come off to stop. Then, a KOH anisotropic etching solution obtained by mixing 1 mol / L isopropanol (IPA) and 5 mol / L KOH was used to etch to fabricate Si wedges. The temperature of the etching solution is 60° C. to 63° C., and the etching time is 6 to 7 minutes. Do not stir the corrosion solution during the corrosion process. A certain proportion of isopropanol can increase the corrosion rate ratio of different crystal planes R(111) / (100). The corrosion container should be relatively airtight, and isopropanol should also be added to the water bath to maintain The stability of the ratio of isopropanol in the corrosion solution. Finall...

example 2

[0033] 1) Fabrication and etching of the metal mask layer on the substrate. First, a layer of 10nm thick metal Cr is magnetron sputtered on the Si substrate, and then a photoresist mask pattern with a width of 2um is produced on the metal Cr by a photolithography process. Dry the sample and place it in the prepared solution of corroding metal Cr, the solution is ammonium cerium nitrate (H 4 CeN 2 o 3 ): Glacial acetic acid (C 2 h 4 o 2 ): deionized water=10g: 2.5mL: 50g, after about 3 minutes, the patterned Cr mask layer can be seen.

[0034] Then, the substrate is subjected to alternate compound deep etching by ICP, and the etching gas and passivation gas are respectively SF 6 and C 4 f 8 . Place the silicon wafer sample protected by the Cr mask layer in the reaction chamber, and after the pressure in the chamber is pumped to 2-3Pa by the mechanical pump, continue to vacuum to 3.0×10 -3 Pa, respectively circulating the reaction gas SF 6 and C 4 f 8 , the flow rat...

example 3

[0039] 1)Al 2 o 3 of etching. Using photoresist AZ4620 on Al 2 o 3 A strip mask pattern with a width of 4um and a height of 4um is fabricated on the substrate, and then ICP etching is performed. Two steps are used for etching: in the first step, the ICP power and bias power are set to 1475W and 290W respectively, the chamber tray temperature is 25°C, BCl 3 Gas flow rate is 85cm 3 / min; In the second step, increase the bias power to 450W. At this time, the photoresist has been completely etched. Through a high bias power, the sapphire substrate is etched quickly, making the edge of the cone more straight .

[0040] 2) CVD in-situ growth of graphene. In edged Al 2 o 3 A layer of 200nm thick metallic Ni was deposited on the substrate as a catalyst. The growth temperature is 1000°C, the heating rate is 0.5°C / s, the growth time is 1h, CH 4 with H 2 The flow ratio is 10sccm: 40sccm.

[0041] After the growth is finished, place the sample in 0.5mol / L FeCl3 solution for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com