Metal molybdenum substrate-based field-induced electron-emitted cathode array and preparation method thereof

A field electron emission, molybdenum substrate technology, used in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of low emission current density, achieve good shape consistency, high consistency, Effect of Field Emission Current Density Increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific embodiments and accompanying drawings.

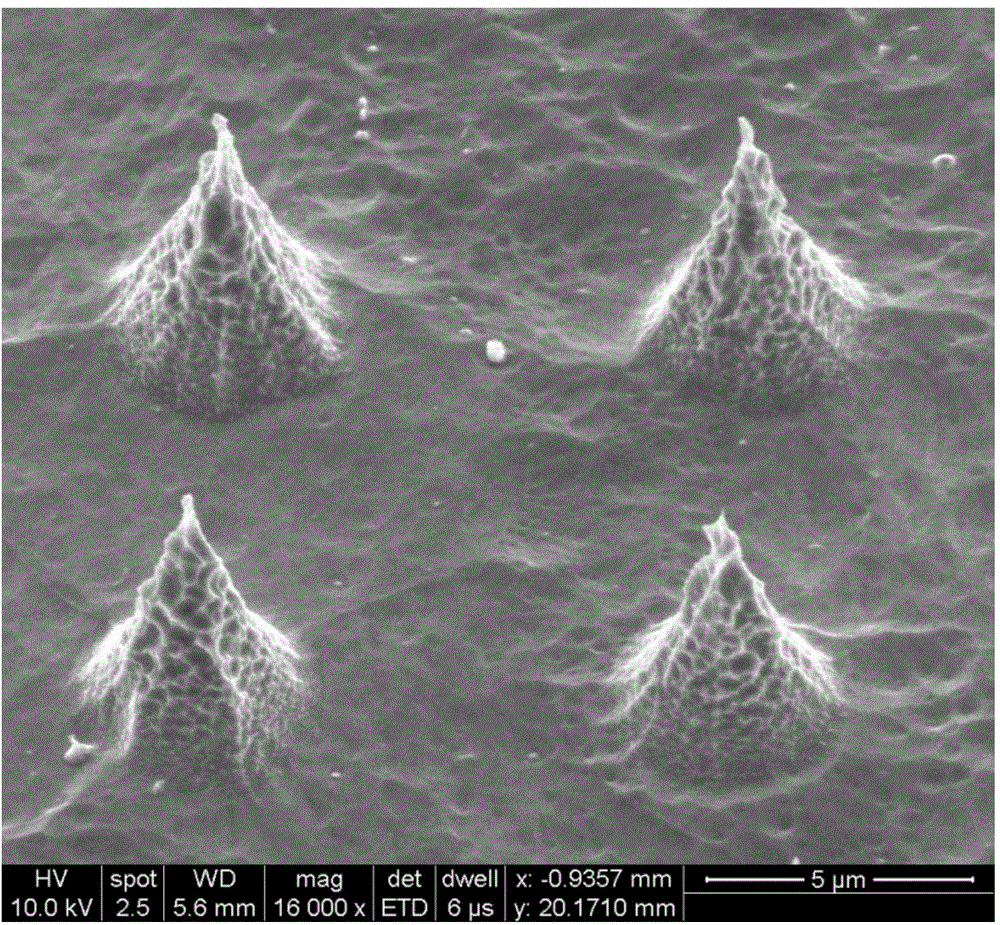

[0028] Such as figure 1 As shown, the field electron emission cathode array based on the metal molybdenum substrate process in this embodiment is formed by equidistant and dense distribution of single pointed cones with very high shape consistency. The distance between the tips of adjacent molybdenum cones is usually 1-100 microns, the height of a single molybdenum cone is usually 1-20 microns, and the radius of the bottom surface is usually 0.5-10 microns. In this embodiment, the distance between the tips of adjacent cones is 10 microns, the height of a single cone is 6 microns, and the radius of the bottom surface is 2.5 microns.

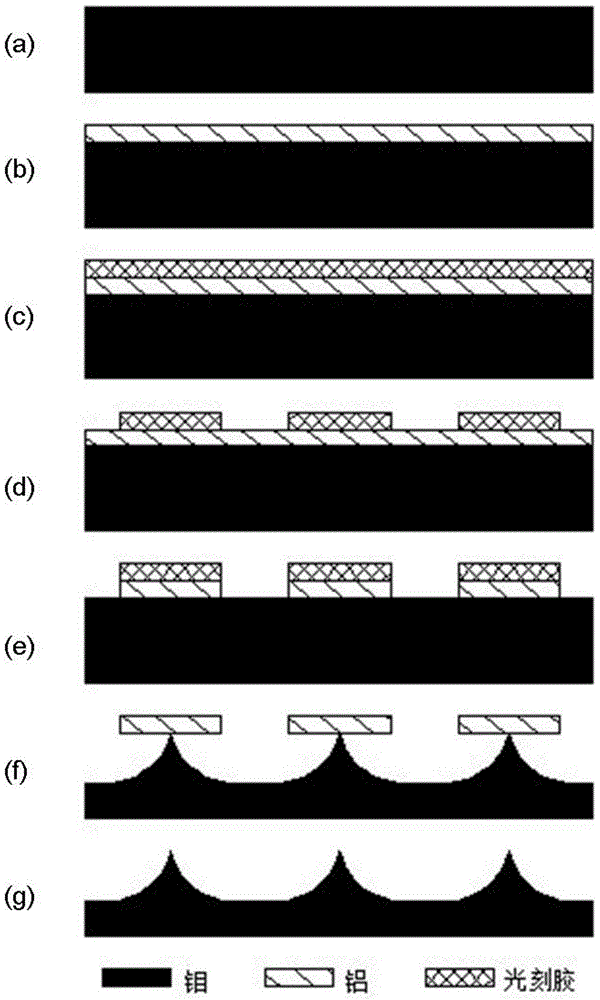

[0029] figure 2 It is the process flow chart of the field electron emission cathode array based on the metal molybdenum substrate process of this embodiment, the field electron emission cathode array is manufactured b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com