Method for improving field emission performance of carbon nano tube by microwave hydrogen plasma treatment

A technology of plasma and carbon nanotubes, which is applied in the field of preparation and application of nanomaterials, can solve the problems of shortening the service life of carbon nanotube-based field emission cathodes, poor field emission stability, and burning of effective field emission points, so as to improve field emission. The effect of emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

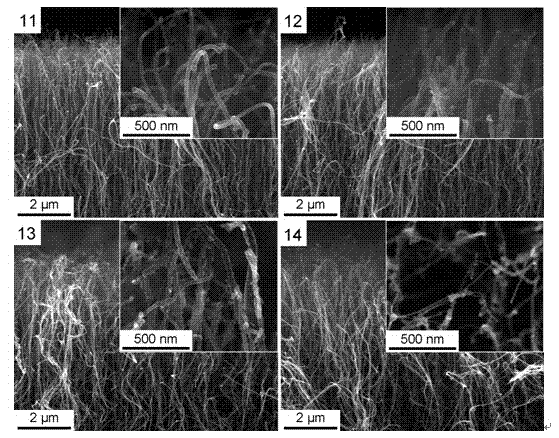

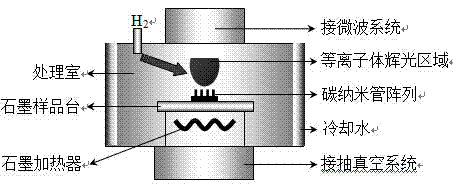

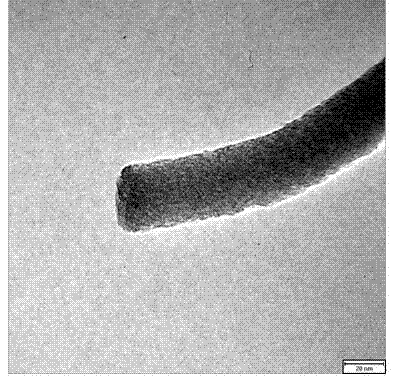

Image

Examples

Embodiment 1

[0039] (1) Preparation of clean silicon wafer substrate:

[0040] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

[0041] (2) Deposition of iron catalyst by magnetron sputtering:

[0042] The deposition of the iron catalyst was carried out in a magnetron sputtering device (commercially available). Prior to this, the silicon single wafer was pretreated by bombardment with energetic iron ions in a metal vapor vacuum arc ion source (MEVVA source, commercially available). The iron ion energy was about 15keV, the beam current was 10 mA, and the processing time For 15 minutes, this treatment can effectively improve the bonding force between carbon nanotubes and silicon substrates; then place the silicon ...

Embodiment 2

[0052] (1) Preparation of clean silicon wafer substrate:

[0053] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

[0054] (2) Deposition of iron catalyst by magnetron sputtering:

[0055] The deposition of the iron catalyst was carried out in a magnetron sputtering device (commercially available). Prior to this, the silicon single wafer was pretreated by bombardment with energetic iron ions in a metal vapor vacuum arc ion source (MEVVA source, commercially available). The iron ion energy was about 15keV, the beam current was 10 mA, and the processing time For 15 minutes, this treatment can effectively improve the bonding force between carbon nanotubes and silicon substrates; then place the silicon ...

Embodiment 3

[0065] (1) Preparation of clean silicon wafer substrate:

[0066] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

[0067] (2) Deposition of iron catalyst by magnetron sputtering:

[0068] The deposition of the iron catalyst was carried out in a magnetron sputtering device (commercially available). Prior to this, the silicon single wafer was pretreated by bombardment with energetic iron ions in a metal vapor vacuum arc ion source (MEVVA source, commercially available). The iron ion energy was about 15keV, the beam current was 10 mA, and the processing time For 15 minutes, this treatment can effectively improve the bonding force between carbon nanotubes and silicon substrates; then place the silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com