Isolated gate controlled transverse field emission transistor and driving method thereof

A driving method and lateral field technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as the influence of carrier mobility and current density, and the small channel length of MOS field effect transistors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

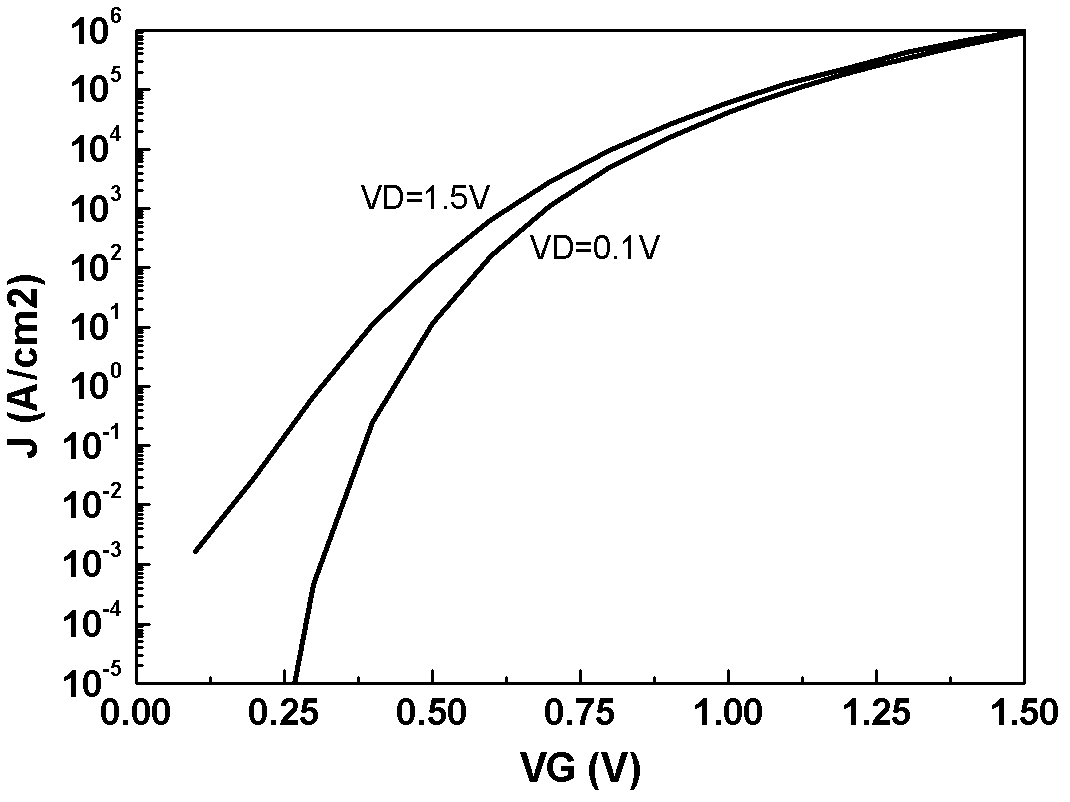

[0038] The performance of conventional MOS field effect transistors in the prior art is limited by the transport characteristics of carriers in the crystal lattice of the channel region, and it is difficult to meet the requirements of continuous development of the process.

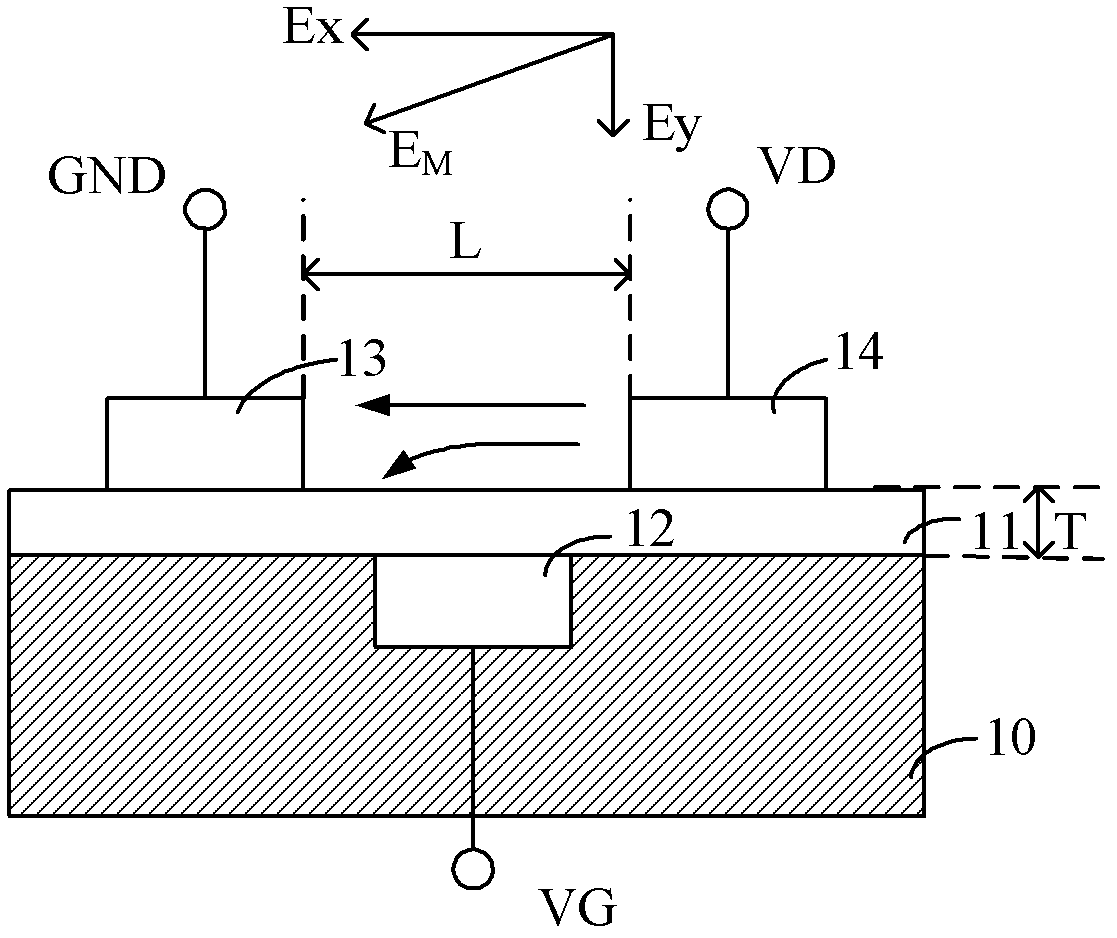

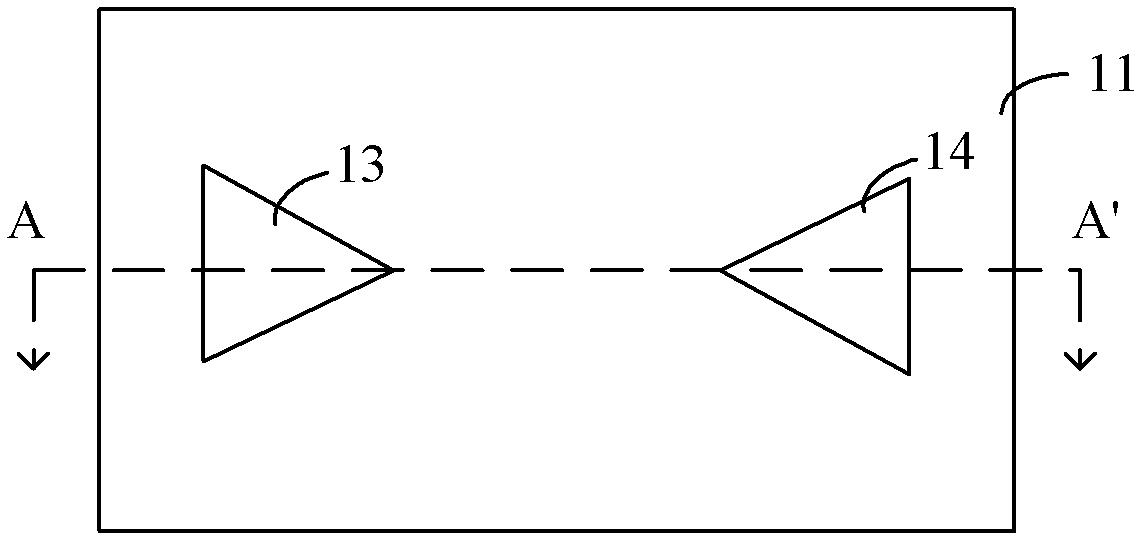

[0039] An embodiment of the present invention provides an insulated gate-controlled lateral field emission transistor, comprising a first gate dielectric layer, a first gate electrode, a collector and an emitter, wherein the first gate electrode is located on the first surface of the first gate dielectric layer The collector and the emitter are located on the second surface of the first gate dielectric layer, on both sides of the first gate electrode, and the collector and the emitter are insulated from each other with a gap between them. When driving it, a driving voltage is applied between the collector and the emitter, so that the emitter emits electrons to the collector to generate a field emission curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com