Field emission triode structure based on graphene

A graphene and field emission technology, applied in the direction of control electrodes, parts of discharge tubes/lamps, electrical components, etc., can solve the problems of reducing the utilization rate of electrons, difficult processing and preparation, etc., to avoid electron beam focusing and emission current. Mutual influence, the effect of improving the total field emission current and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

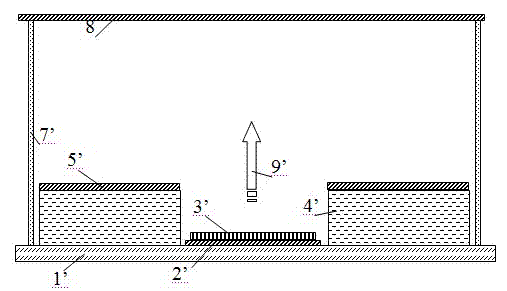

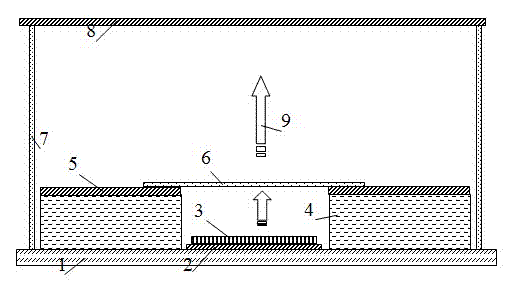

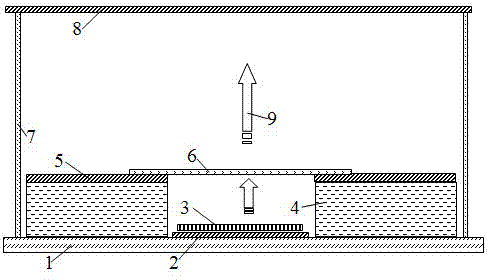

[0018] The present invention will be described below with reference to the accompanying drawings.

[0019] The present invention proposes a graphene-based field emission triode structure, the field emission triode structure includes a cathode substrate, a cathode electrode, a field emitter for emitting electron beams, an insulating dielectric layer, a grid electrode, and a graphene layer , support body and anode; Wherein:

[0020] A cathode electrode is arranged on the cathode substrate, a field emitter is arranged on the cathode electrode, an insulating medium layer is located on the cathode substrate, a grid electrode is arranged on the insulating medium layer, and a graphene layer is arranged on the grid electrode. The anode is located above the cathode substrate and opposite to the cathode substrate, and is fixed to the cathode substrate through a support. The electron beam emitted by the field emitter is modulated by the grid electrode and bombards the anode through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com