Double-wall pipeline for the connection of fuel-gas valve set and engine on LNG ship and installation method of double-wall pipeline

A technology for LNG ships and dual-fuel engines, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of inability to meet the requirements of design pressure, unsatisfactory effects, and difficult construction, and achieves simple and practical structure. Easy, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

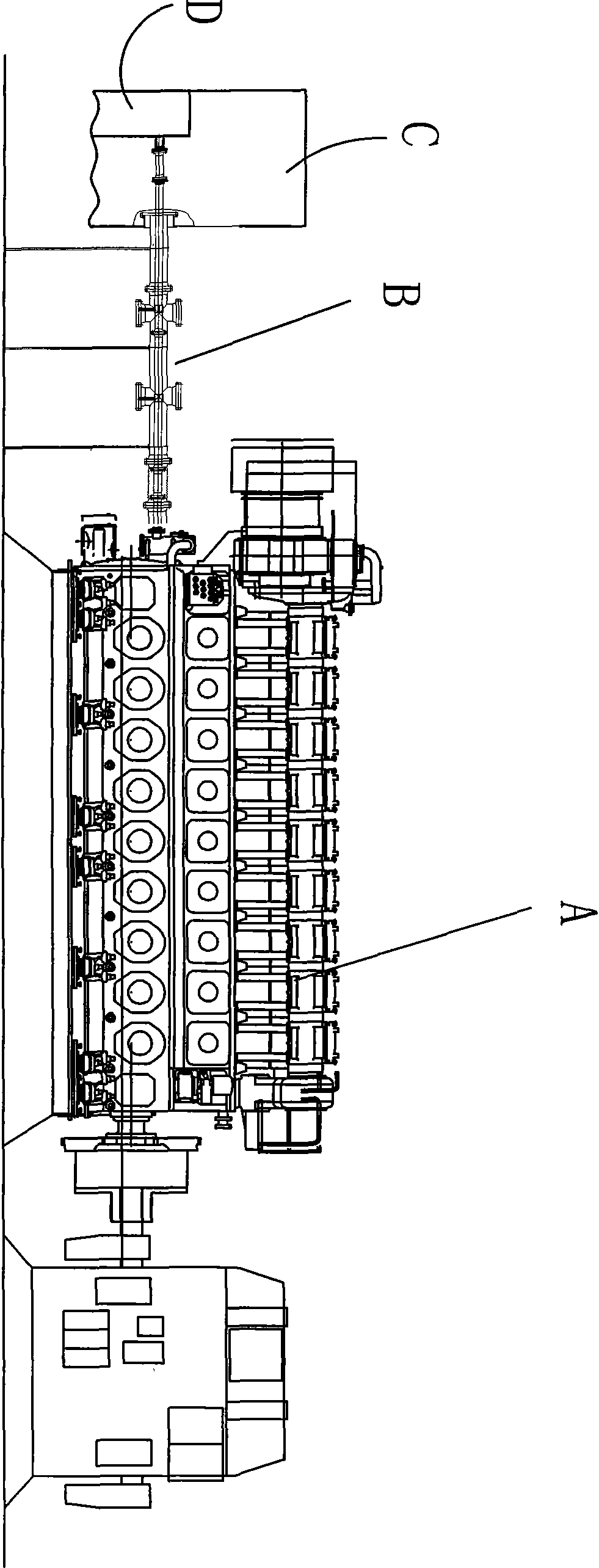

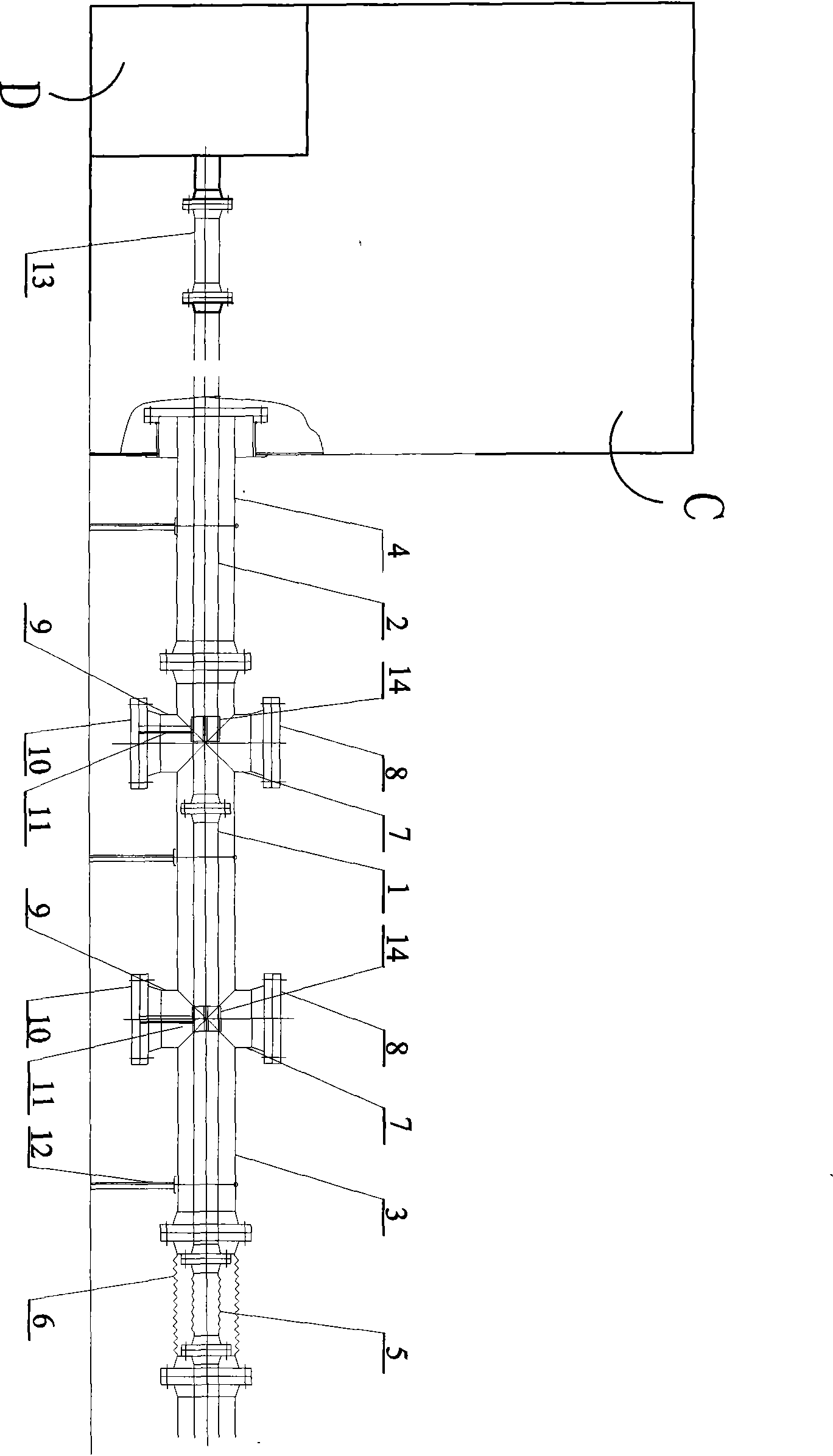

[0041] The double-wall pipe design scheme applied to the 160,000 cubic meters electric propulsion LNG ship under research and development.

[0042] First, double wall tube structure:

[0043] ① The inner pipe is made of Φ114×6 ordinary steel pipe, the length of the No. 1 inner pipe is 2500mm, the length of the No. 2 inner pipe is 2200mm, and the standard flanges of 10100GB2506-89 are used at both ends;

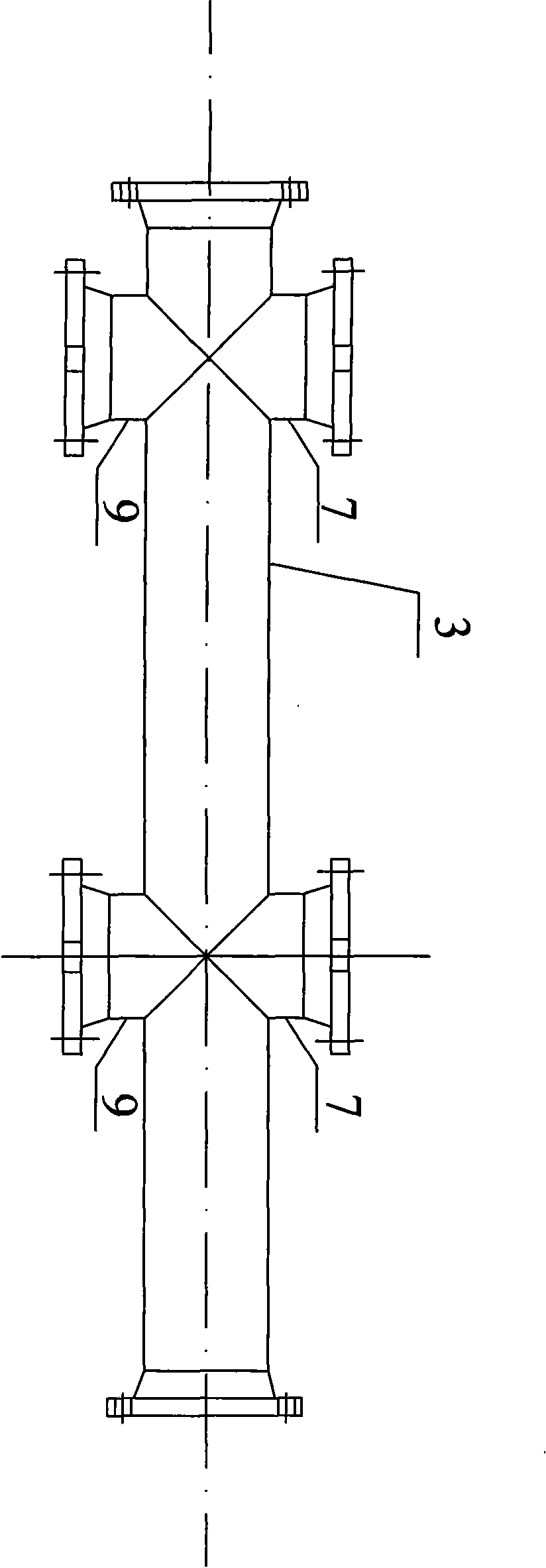

[0044] ② The outer pipe is made of Φ325×8 ordinary steel pipe, the second outer pipe is 1250mm long, the first outer pipe is a combined structure, and there are upper and lower branch pipes of DN300 diameter on it, and the standard flanges of 10300GB2506-89 are used at both ends;

[0045] ③ The two ends of the upper and lower branch pipes adopt the standard flange of 10300GB2506-89, and the end cover adopts the standard blind flange of this series;

[0046] ④The inner bellows adopts the specification of DN100PN10, and the outer bellows adopts the specification of DN300PN10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com