Puncture-resistant heat-shrinkable double-wall pipe and preparation method thereof

A heat-shrinkable, double-walled tube technology, applied in the field of heat-shrinkable tubes, can solve the problems of potential safety hazards, loss of personnel and property, poor fluidity of the inner rubber layer, etc., to improve mechanical strength and tensile strength, excellent mechanical Strength and tensile strength, the effect of alleviating the trouble of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

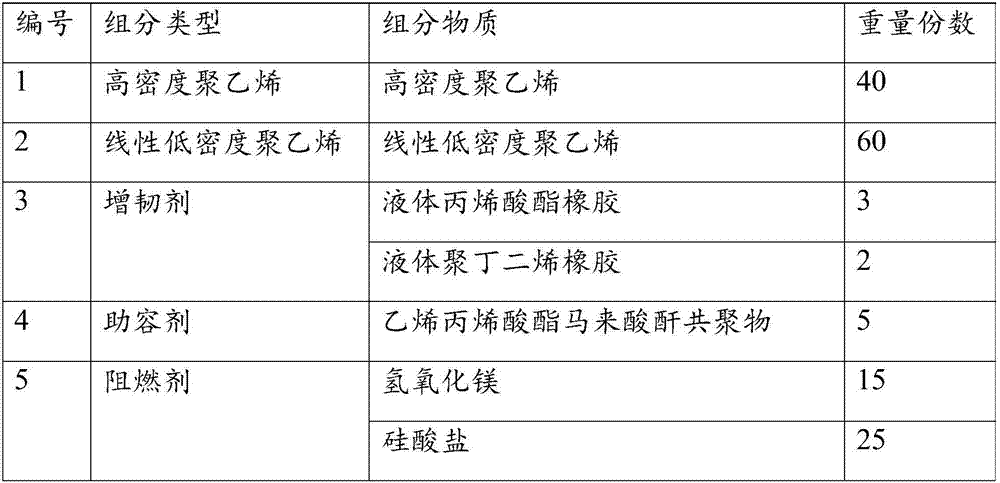

[0036] A raw material for a puncture-resistant heat-shrinkable double-walled tube (according to parts by weight):

[0037] (1) The outer skin material includes the following components: 40 parts of high-density polyethylene with a melt index of 0.1g / 10min, 60 parts of linear low-density polyethylene with a melt index of 0.5 / 10min, liquid acrylate rubber and liquid polybutylene 5 parts of the mixture of olefin rubber, 5 parts of ethylene acrylate maleic anhydride copolymer, 50 parts of the mixture of magnesium hydroxide, silicate, melamine cyanurate, 10 parts of the mixture of zinc oxide, antimony trioxide and amine polyphosphate part, 0.2 part of silicone oil, 1 part of tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol, and 0.5 part of trimethylolpropane trimethacrylate. As shown in Table 1:

[0038] Table 1:

[0039]

[0040]

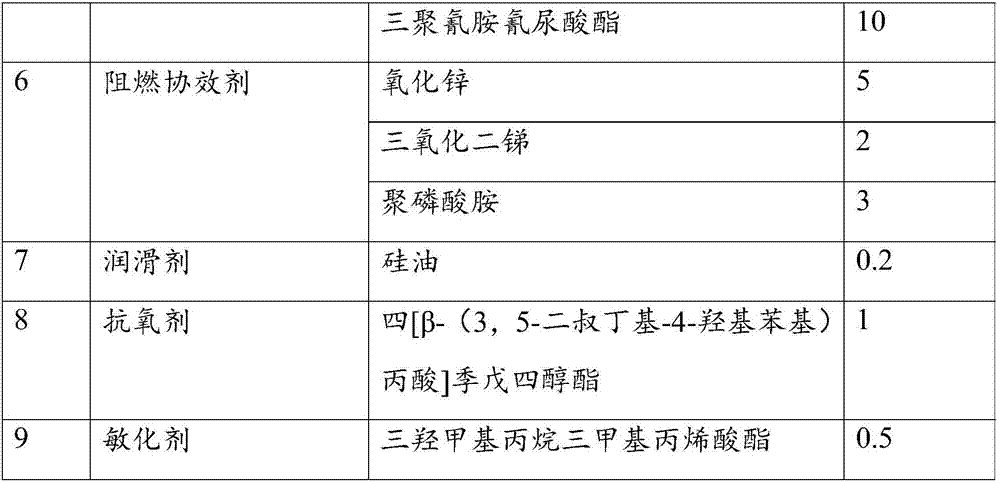

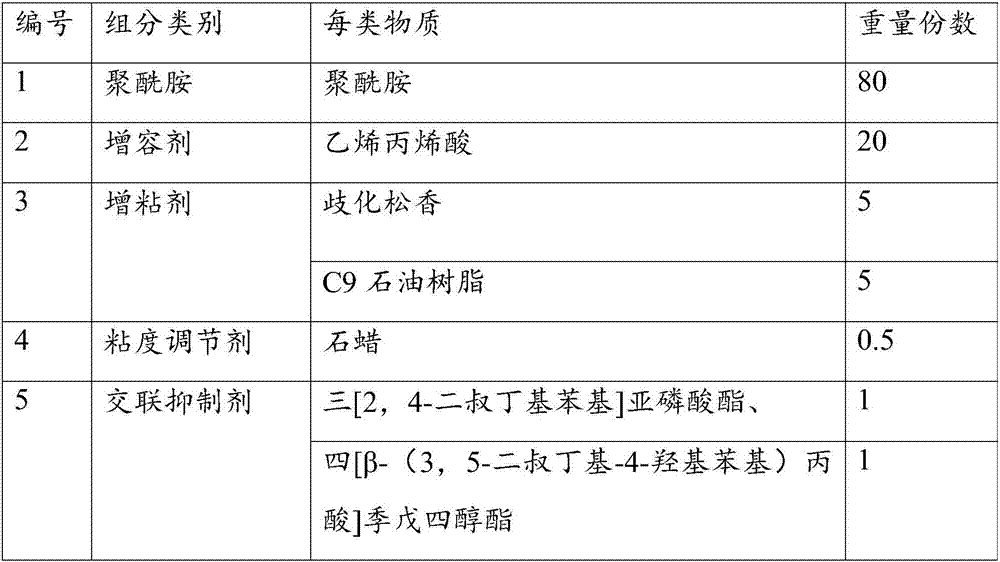

[0041]The inner sizing material comprises the following components: 80 parts of polyamide with a relative molecu...

Embodiment 2

[0053] A raw material for a puncture-resistant heat-shrinkable double-walled tube (according to parts by weight):

[0054] (1) The outer skin material includes the following components: 80 parts of high-density polyethylene with a melt index of 5g / 10min, 20 parts of linear low-density polyethylene with a melt index of 5g / 10min, 20 parts of liquid acrylate rubber, ethylene vinyl acetate 2 parts of ester maleic anhydride copolymerization, 20 parts of a mixture of aluminum hydroxide, decabromodiphenylethane and melamine cyanurate, 25 parts of a mixture of zinc oxide and colloidal antimony pentoxide, 1 part of silicone oil, tetrakis[β- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.5 part, trimethylolpropane trimethacrylate 2 parts. As shown in Table 3:

[0055] Form 3:

[0056]

[0057]

[0058] The inner sizing material includes the following components: 60 parts of polyamide with a relative molecular weight of 100,000 and a softening point of...

Embodiment 3

[0071] A raw material for a puncture-resistant heat-shrinkable double-walled tube (according to parts by weight):

[0072] (1) The outer skin material includes the following components: 60 parts of high-density polyethylene with a melt index of 1g / 10min, 40 parts of linear low-density polyethylene with a melt index of 1.5g / 10min, ethylene-octene copolymer and chlorinated polyethylene 10 parts of the mixture of ethylene acrylate maleic anhydride copolymer, 3 parts of the mixture of ethylene acrylate maleic anhydride copolymer, 40 parts of the mixture of magnesium hydroxide, silicate, melamine cyanurate, 40 parts of the mixture of zinc oxide, antimony trioxide and amine polyphosphate, 0.5 part of silicone oil, 0.8 part of tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, 1.5 part of trimethylolpropane trimethacrylate, as shown in Table 5 :

[0073] Form 5:

[0074]

[0075] The inner sizing material includes the following components: 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com