Heat exchange type ventilator

A ventilation device and heat exchange element technology, applied in heating methods, household heating, heat recovery systems, etc., can solve the problems of increased resistance of air supply and exhaust passages, larger overall size of the device, and poor construction. Achieve the effects of eliminating redundant space, realizing miniaturization, and improving air supply performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

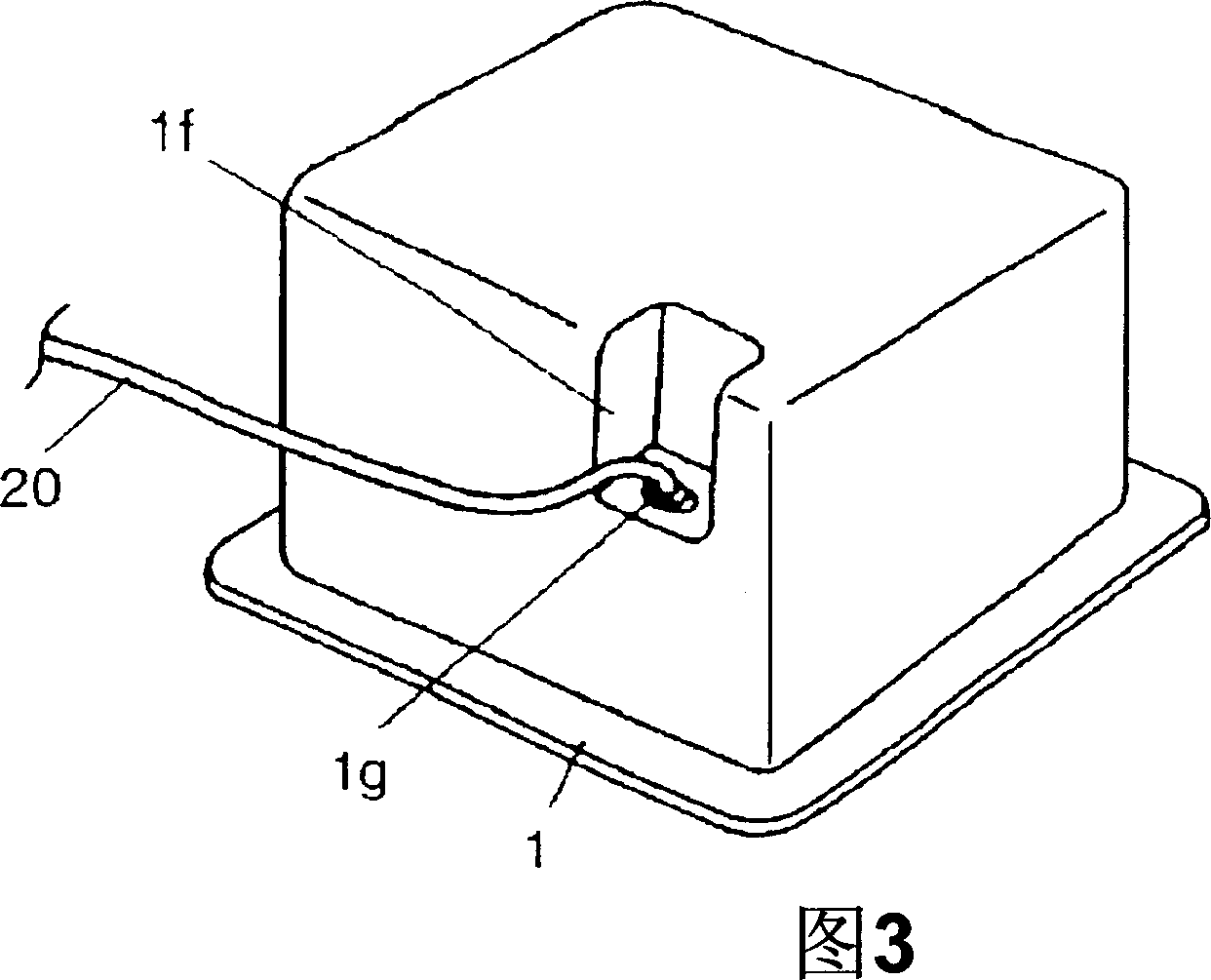

[0041] The heat exchange type ventilator of the present invention is accommodated and installed on the inner side of the top surface, for example.

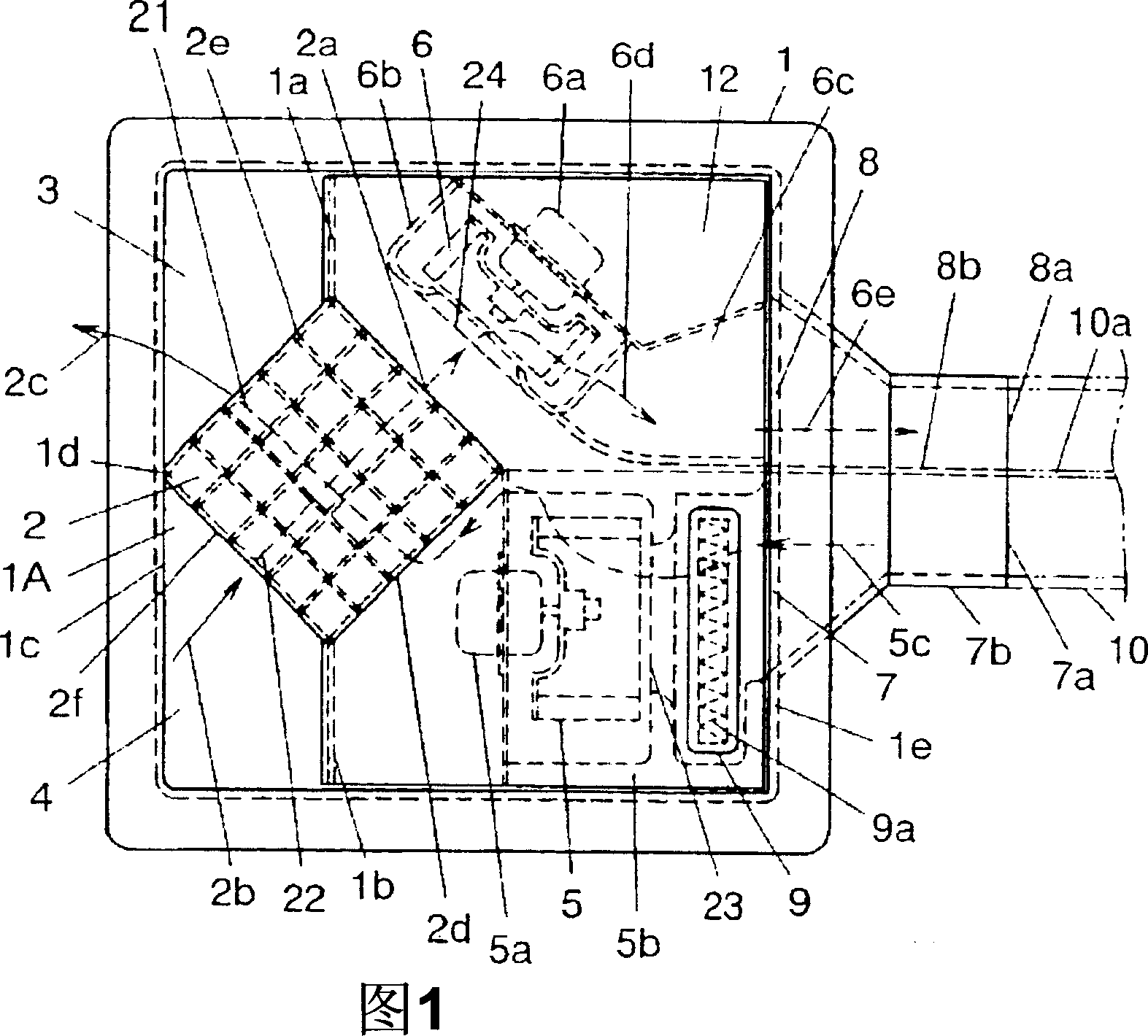

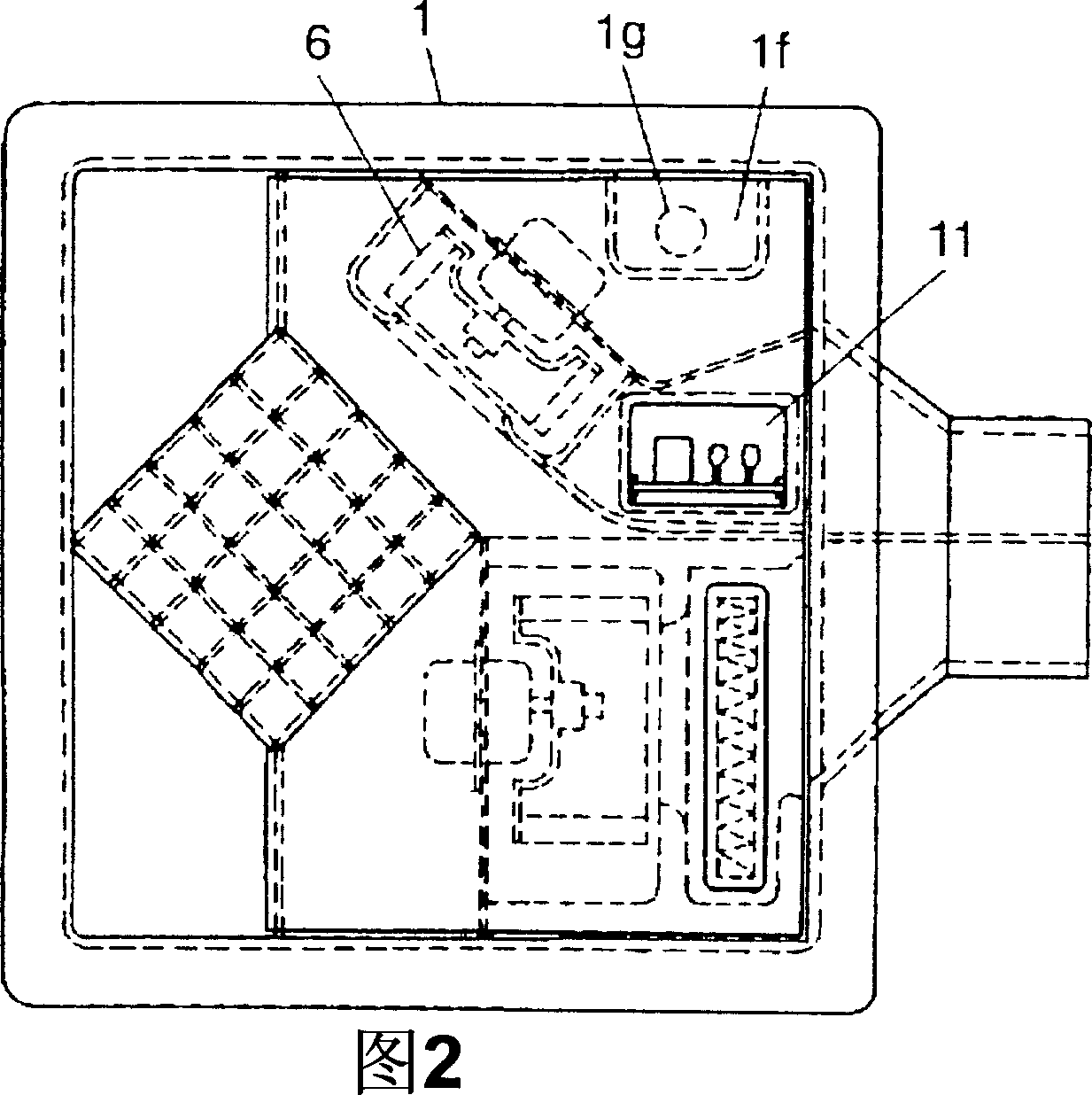

[0042] Fig. 1 is a view showing the structure of the heat exchange type ventilator according to the present invention, viewed from the opening side of the case. As shown in FIG. 1 , the heat exchange type ventilator of the present invention includes a box body having an opening 1A on the lower surface thereof and having a quadrangular cross-section. A plurality of exhaust flow paths 22 and supply flow paths 21 are alternately laminated in the depth direction of the housing 1 through the heat exchange plate so that the exhaust flow paths 22 and the supply flow paths 21 intersect each other. It has a heat exchange element 2 that performs heat exchange between the supply air flow and the exhaust air flow, and reduces energy loss through ventilation. It has the air supply blower 5 formed by the air supply blower motor 5a and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com