fuel cell system

A fuel cell system and fuel system technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of high cost, low catalytic efficiency, and low utilization rate of fuel cell systems, and achieve improved drainage and exhaust performance, faster The effect of high gas flow rate and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

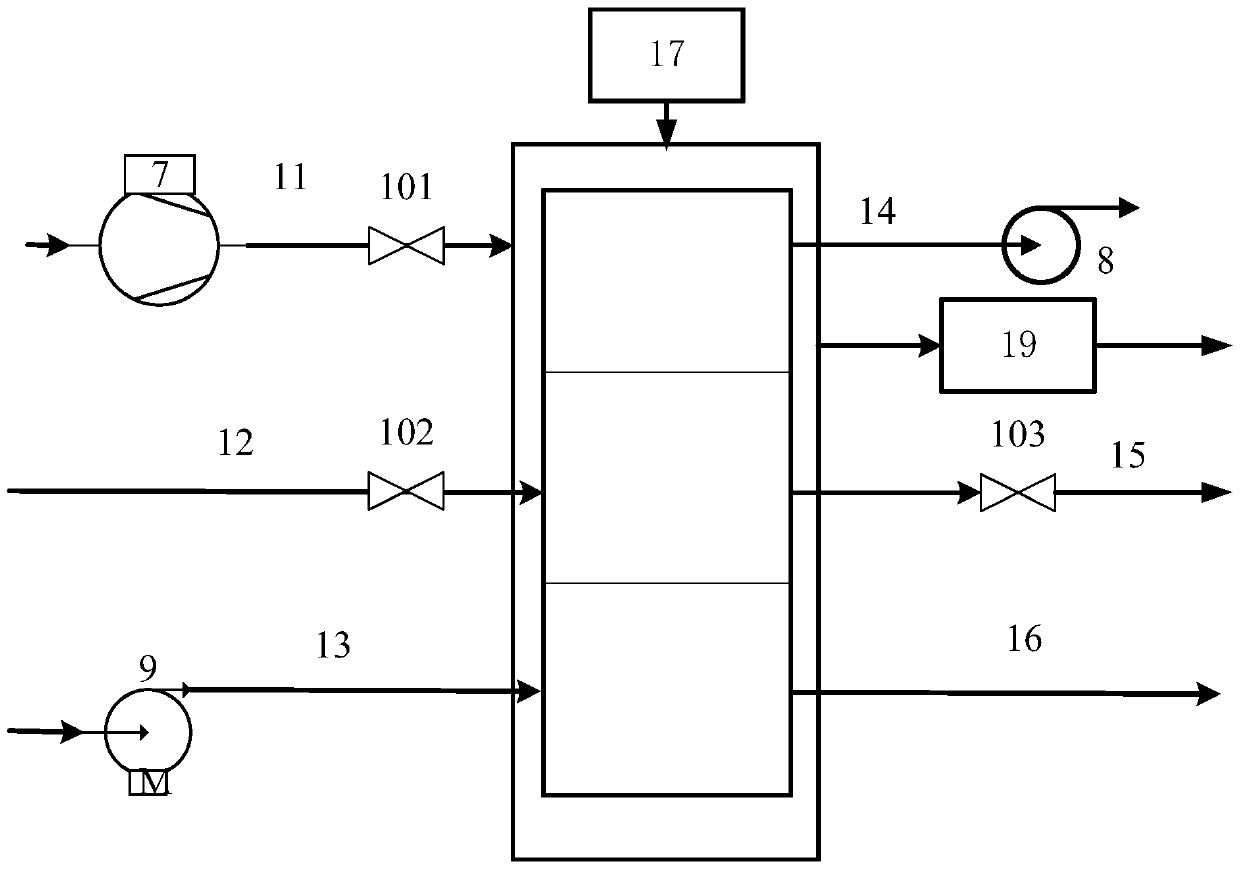

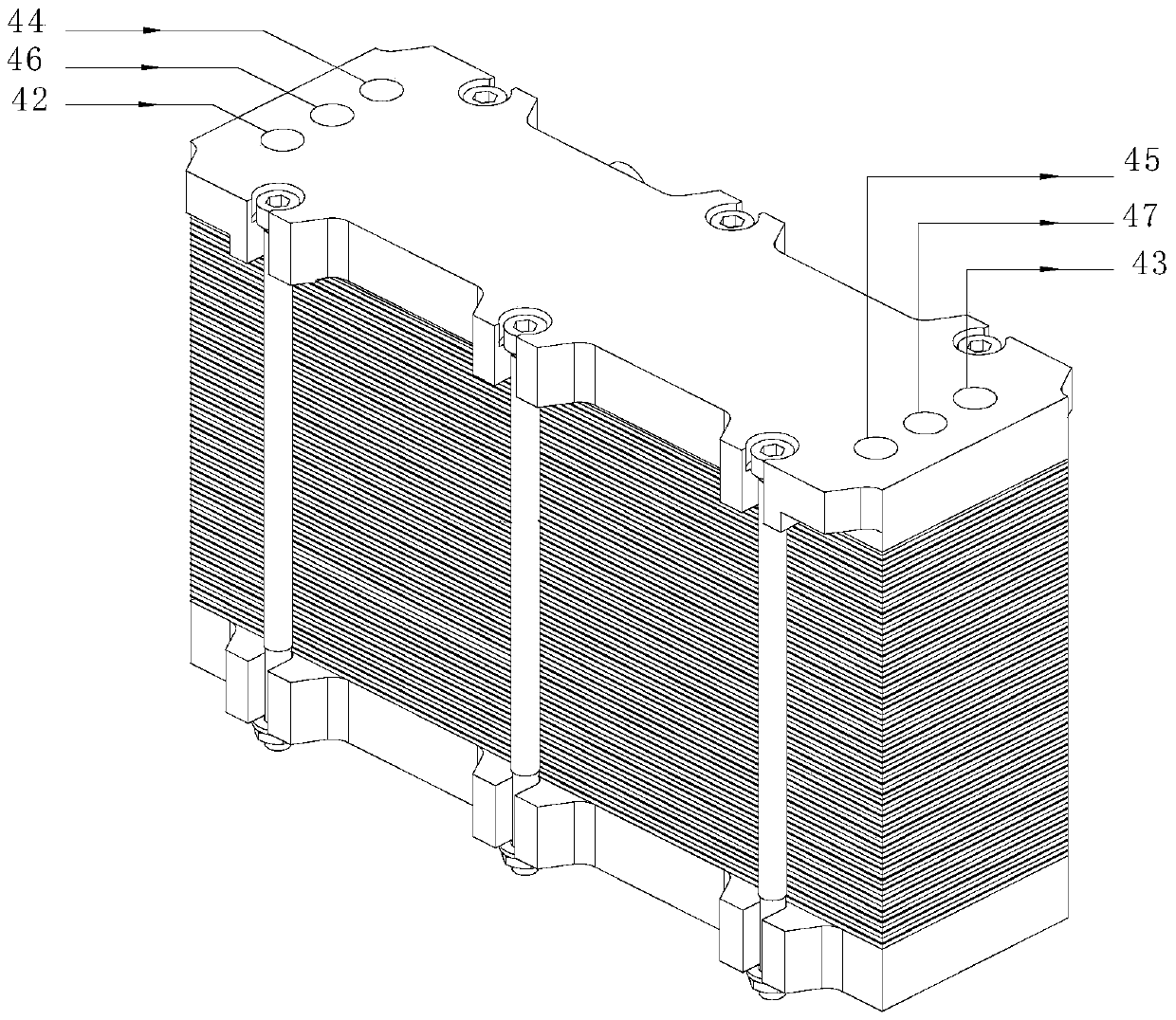

[0041] A fuel cell system such as figure 1 and figure 2 As shown, it includes a fuel cell stack, and a fuel system 12, an oxidant system 11, a cooling system 13 and an exhaust system that are all connected to the fuel cell stack. The above-mentioned oxidant system 11 is connected to the oxidant of the fuel cell stack by an air compressor 7 Inlet 42, and valve 101 is arranged on this pipeline, and the oxidant outlet 43 of fuel cell stack connects oxidant outlet pipeline 14; Fuel system 12 is connected to the fuel inlet 44 of fuel cell stack by fuel storage tank through pipeline, and on this pipeline A valve 102 is provided, and the fuel outlet 45 of the fuel cell stack is connected to the fuel outlet pipeline 15, and the fuel outlet pipeline 15 is provided with a valve 103; the above-mentioned cooling system 13 is connected to the cooling fluid of the fuel cell stack by the cooling fluid compressor 9 through a pipeline. The inlet 46, the cooling fluid outlet 47 of the fuel ce...

Embodiment 2

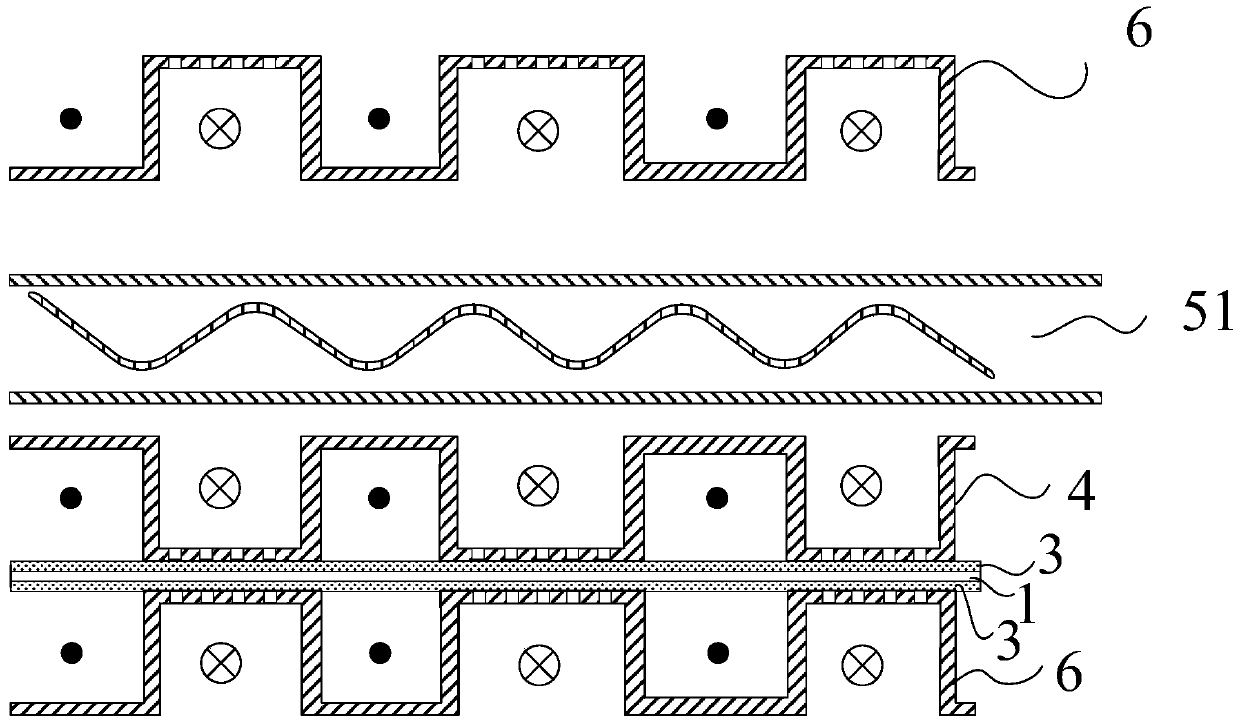

[0051] This embodiment proposes a fuel cell system, the structure of the fuel cell stack in the fuel cell system is as follows Figure 8 As shown, the fuel cell stack has an oxidant inlet 42, an oxidant outlet 43, a fuel inlet 44 and a fuel outlet 45, and the MEA and the cathode plate 4 and the anode plate 6 in the single cell are clamped as Figure 7 As shown, the single cell is composed of a cathode plate 4 and an anode plate 6 sandwiching an MEA, and the MEA includes a proton exchange membrane 1 and catalytic layers 2 arranged on both sides of the proton exchange membrane 1 (such as Figure 4 shown) and the fluid transport layer 3 arranged outside the catalytic layer 2, wherein the cathode plate 4 and the anode plate 6 are arranged between the separator 5, the separator 5 is an air-tight plate, preferably a solid plate, the cathode plate 4 and the anode One side of each plate 6 is provided with a fluid inlet passage for the inlet end, and the other side is provided with a f...

Embodiment 3

[0053] The similarities between this embodiment and Embodiment 1 will not be described, and only the differences will be described.

[0054] The significant difference between this embodiment and Embodiment 1 is that the fuel cell system in this embodiment does not include an air extraction device, and the oxidant system 11 is provided by an air compressor 7 (such as figure 1 shown) is connected to the oxidant inlet of the fuel cell stack through pipelines to form a positive pressure on the inlet side of the cathode plate 4 (relative to an atmospheric pressure, that is, greater than 1 atmospheric pressure), and form a pressure difference with the outlet side of the cathode plate 4. In principle, the fuel system 12 is connected to the fuel inlet 44 of the fuel cell stack by the fuel storage tank through a pipeline to form a positive pressure on the inlet side of the anode plate 6 (relative to an atmospheric pressure, that is, greater than 1 atmospheric pressure), and the anode p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com