Flow wet, team humidity measuring instrument of bilayerpipe direct heating type

A technology of flowing wet steam and humidity measuring instrument, which is applied in the direction of material moisture content, etc., can solve the problems that the measurement technology does not solve, does not consider heat loss, and the accuracy of humidity measurement by heating method is difficult to guarantee, and achieves the effect of zero heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

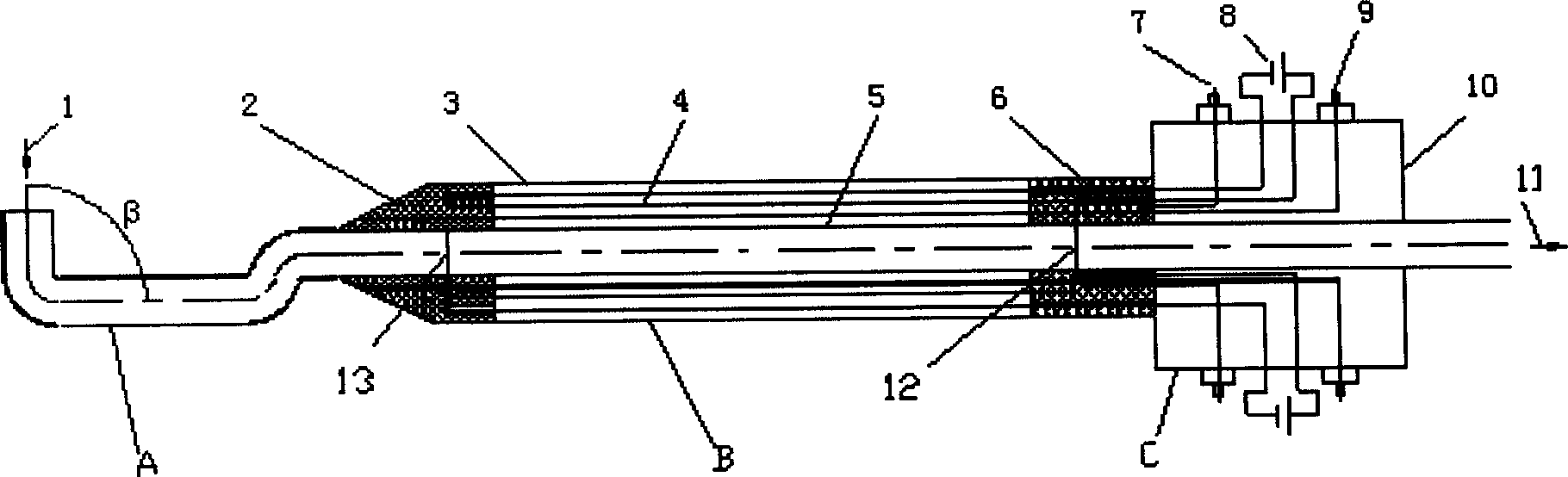

[0019] refer to figure 1 As shown, the present invention includes three parts: an inlet section A, a heating section B and an outlet section C; the inlet section A is connected to the heating section B; the heating section B is connected to the outlet section C, and the inner layer heating tube 5 of the heating section B is covered with a middle layer heating tube 4. The middle layer heating tube 4 is covered with an outer layer support tube 3; the inner layer heating tube 5, the middle layer heating tube 4, and the outer layer support tube 3 are insulated from each other, and a distance is left, and one end of the inlet section A and the heating section B passes through The insulated heat insulating connecting piece 2 at the left end is connected, and the outlet section C is connected with the other end of the heating section B through the heat insulating connecting piece 6 insulated at the right end. In the outlet section C, 7 represents the thermocouple joint, 8 represents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com