Bending process of double-layer pipe

A technology of double-layer pipe and pipe bending, which is applied in the field of pipe bending technology of double-layer pipe, can solve the problems of non-compliance with environmental protection requirements, long production cycle, service life of rusted equipment, etc., and meet the requirements of environmental protection and smooth shape The effect of beautiful appearance and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

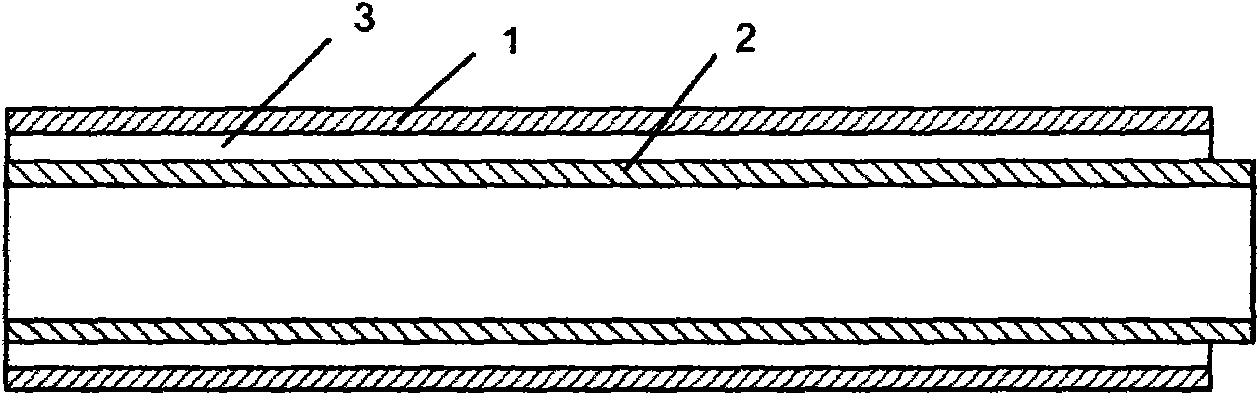

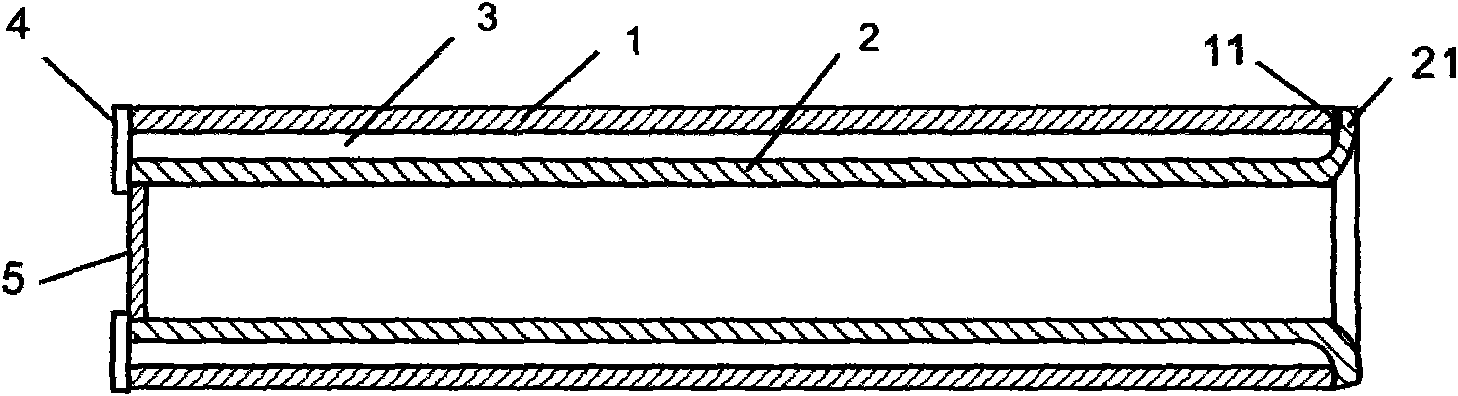

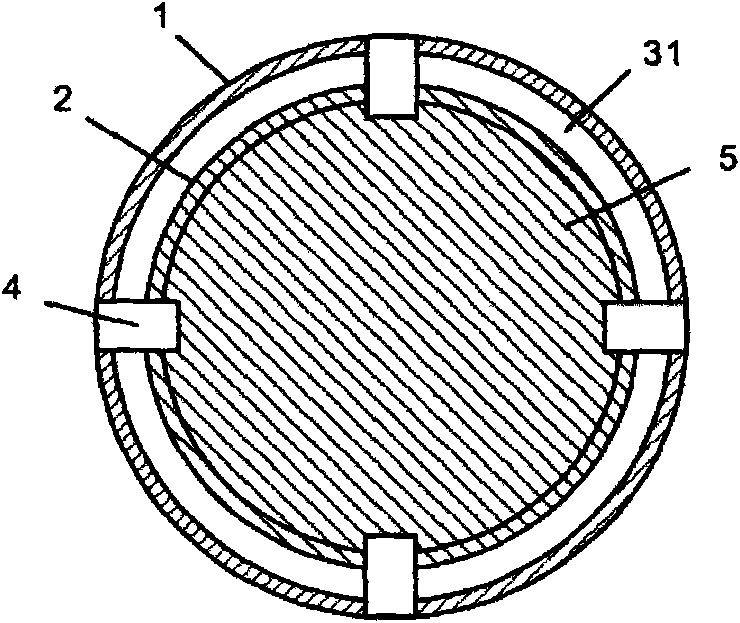

[0052] see Figure 1 ~ Figure 4 Shown:

[0053] Implement a kind of pipe bending technology of double-layer pipe, described technology comprises the steps:

[0054] a. Outer tube 1 blanking;

[0055] b. Inner tube 2 blanking;

[0056] c. Next, one end of the inner layer pipe 2 is made into a flaring end 21;

[0057] d. Then block the other end of the inner tube to make a plugged end;

[0058] e. Next, the inner tube 2 and the outer tube 1 are assembled and welded;

[0059] f. Special solid filler 6 for filling elbow;

[0060] g. Carry out the pipe bending process;

[0061] h. Dissolving elbow special solid filler 6;

[0063] j. Completion inspection.

[0064] Making one end of the inner tube 2 into a flared end 21 in step c refers to expanding the flared end 21 to the extent that the edge and the outer tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com