PET flame-retarding monofilament

A monofilament and fuel-retarding technology, which is applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of PET monofilaments with insufficient flame retardancy, unsuitable application fields, and high hardness, so as to improve flame retardancy and photocuring shrinkage performance, increasing layer spacing and specific surface area, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

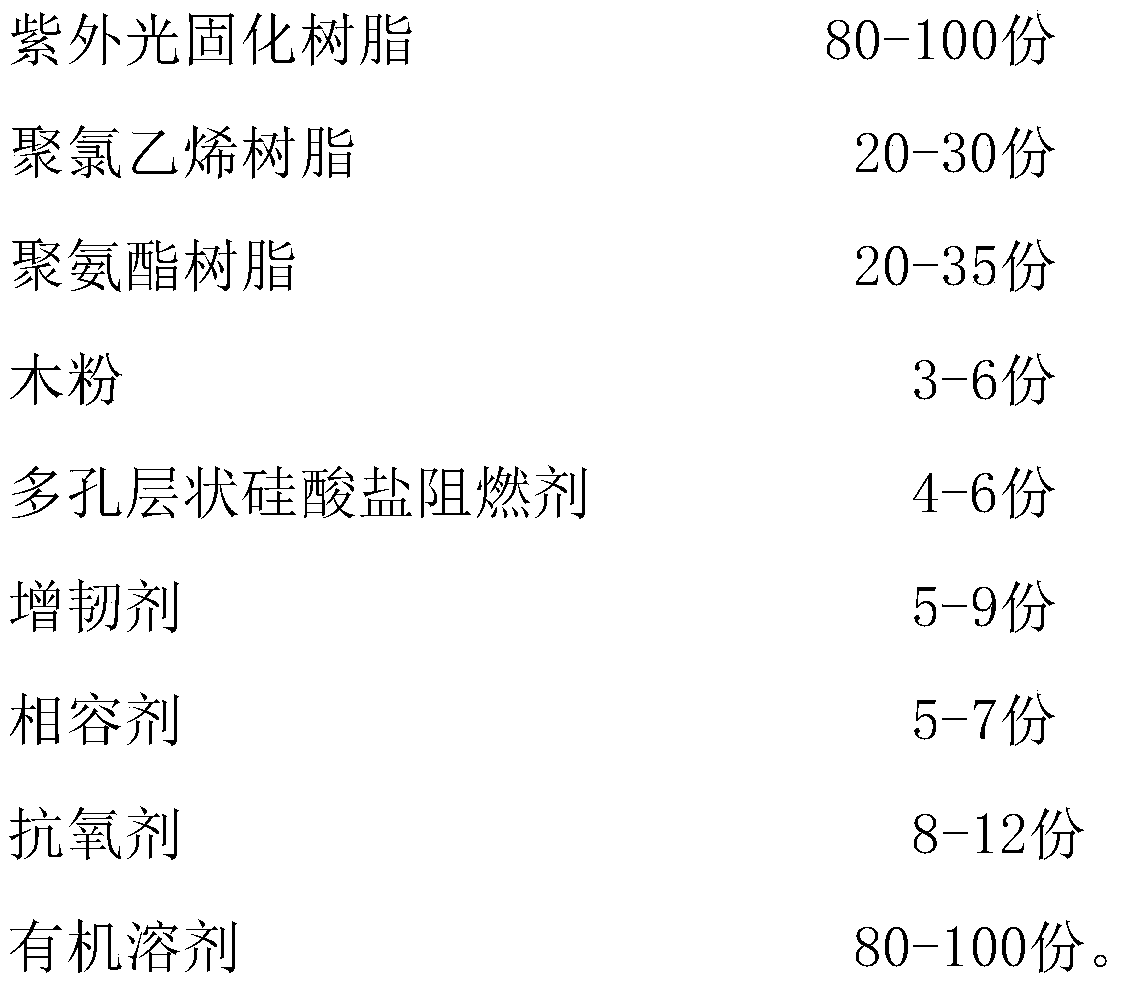

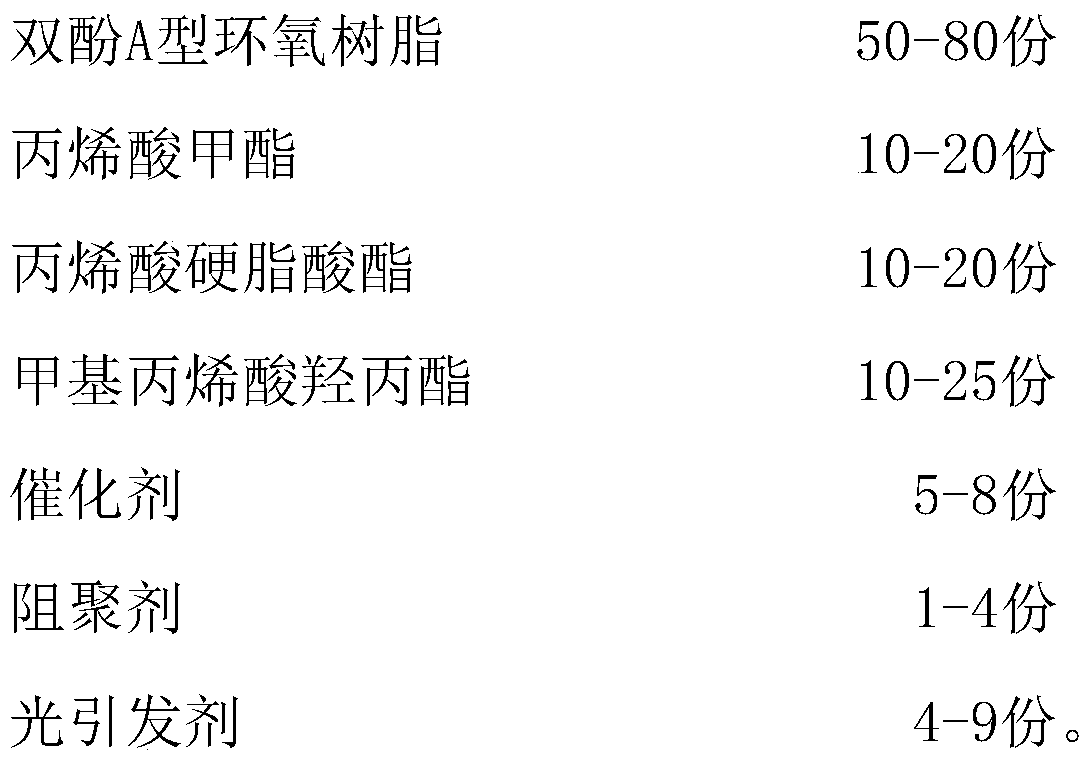

[0040] PET flame-retardant monofilament, it comprises PET core bundle and the flame-retardant layer that is coated on the outside of PET core bundle, and described flame-retardant layer comprises the raw material of following parts by weight:

[0041]

[0042] Specifically, the toughening agent is a mixture of vinyl acetate, epoxidized soybean oil and chlorinated polyethylene in a weight ratio of 2:0.5:2.5; the compatibilizer is tri-p-sec-butylphenyl phosphate, phthalate A mixture of dioctyl formate and methyl methacrylate-butadiene-styrene terpolymer in a weight ratio of 1:1:1; the antioxidants are antioxidant 1076, antioxidant 168 and titanium dioxide by weight The weight ratio is a mixture composed of 1:1:1; the organic solvent is a mixed solution composed of toluene and ethyl acetate in a weight ratio of 3.5:1.

[0043] Wherein, the particle size of the wood powder is 35nm.

[0044] Wherein, the preparation method of described porous layered phosphate flame retardant c...

Embodiment 2

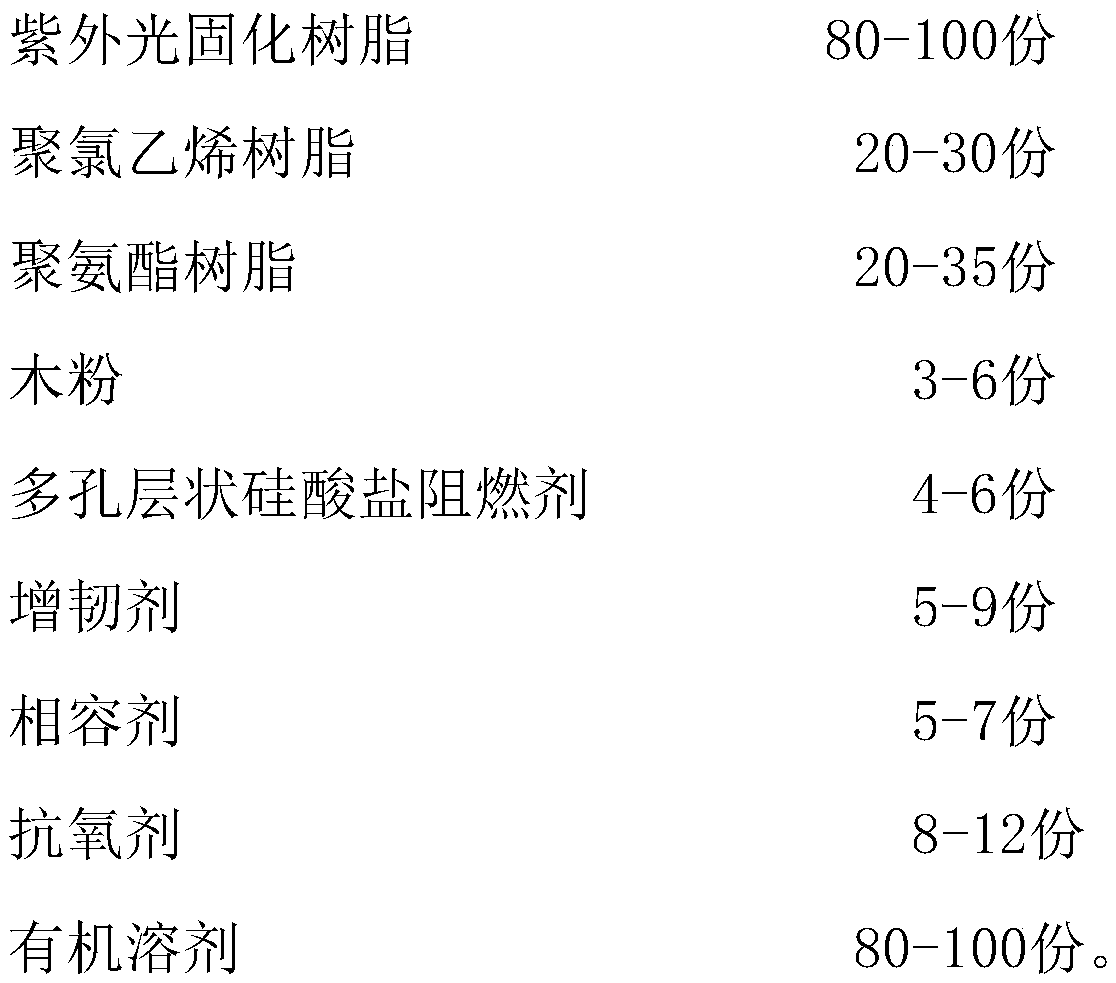

[0062] PET flame-retardant monofilament, it comprises PET core bundle and the flame-retardant layer that is coated on the outside of PET core bundle, and described flame-retardant layer comprises the raw material of following parts by weight:

[0063]

[0064] Specifically, the toughening agent is a mixture of vinyl acetate, epoxidized soybean oil and chlorinated polyethylene in a weight ratio of 1:0.5:2. The compatibilizer is tri-p-sec-butylphenyl phosphate, the antioxidant is antioxidant 1076, and the organic solvent is a mixed solution composed of toluene and ethyl acetate in a weight ratio of 3:1.

[0065] Wherein, the particle size of the wood powder is 20nm.

[0066] Wherein, the preparation method of described porous layered phosphate flame retardant comprises the steps:

[0067] (1) the quaternary phosphorus salt of 4 weight parts is mixed with the inorganic montmorillonite of 20 weight parts, under the protection of inert gas nitrogen, the volume concentration tha...

Embodiment 3

[0085] PET flame-retardant monofilament, it comprises PET core bundle and the flame-retardant layer that is coated on the outside of PET core bundle, and described flame-retardant layer comprises the raw material of following parts by weight:

[0086]

[0087]

[0088] Specifically, the toughening agent is a mixture of vinyl acetate, epoxidized soybean oil and chlorinated polyethylene in a weight ratio of 3:0.5:3. The compatibilizer is dioctyl phthalate. The antioxidant is Antioxidant 168. The organic solvent is a mixed solution composed of toluene and ethyl acetate in a weight ratio of 4:1

[0089] Wherein, the particle size of the wood powder is 50nm.

[0090] Wherein, the preparation method of described porous layered phosphate flame retardant comprises the steps:

[0091] (1) the quaternary phosphorus salt of 10 weight parts is mixed with the inorganic montmorillonite of 30 weight parts, under the protection of inert gas nitrogen, add the ethanol aqueous solution th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com