High-glow-wire flame-retardant polypropylene material for fan heater casing and preparation method for same

A flame-retardant polypropylene and high-glow wire technology, which is applied in the field of polymer materials, can solve problems such as inability to test, achieve the effect of improving flame-retardant effect and overcoming low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

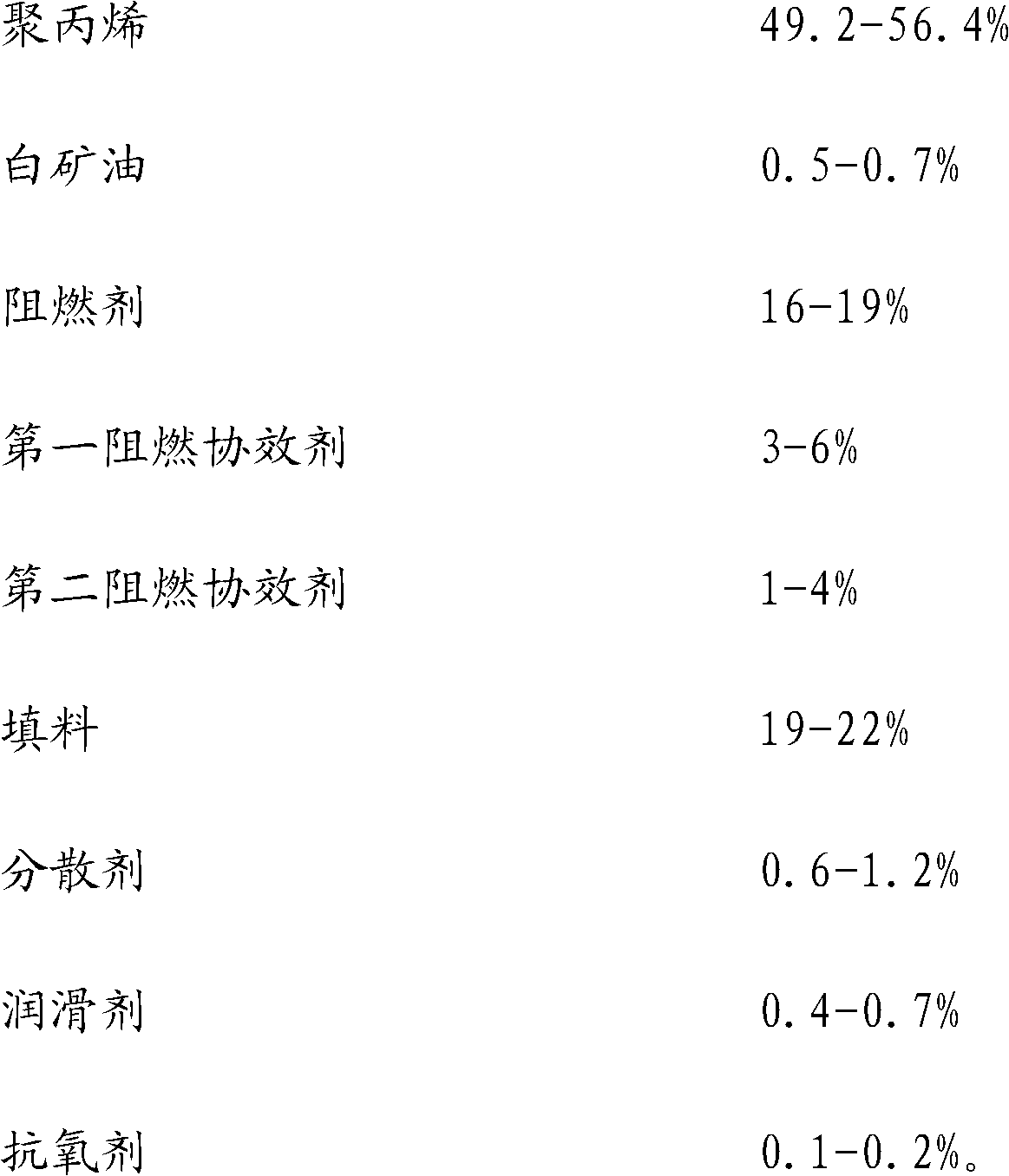

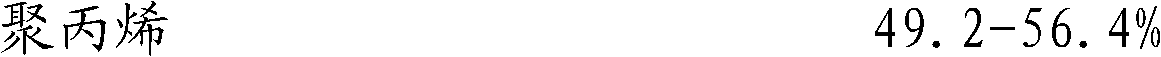

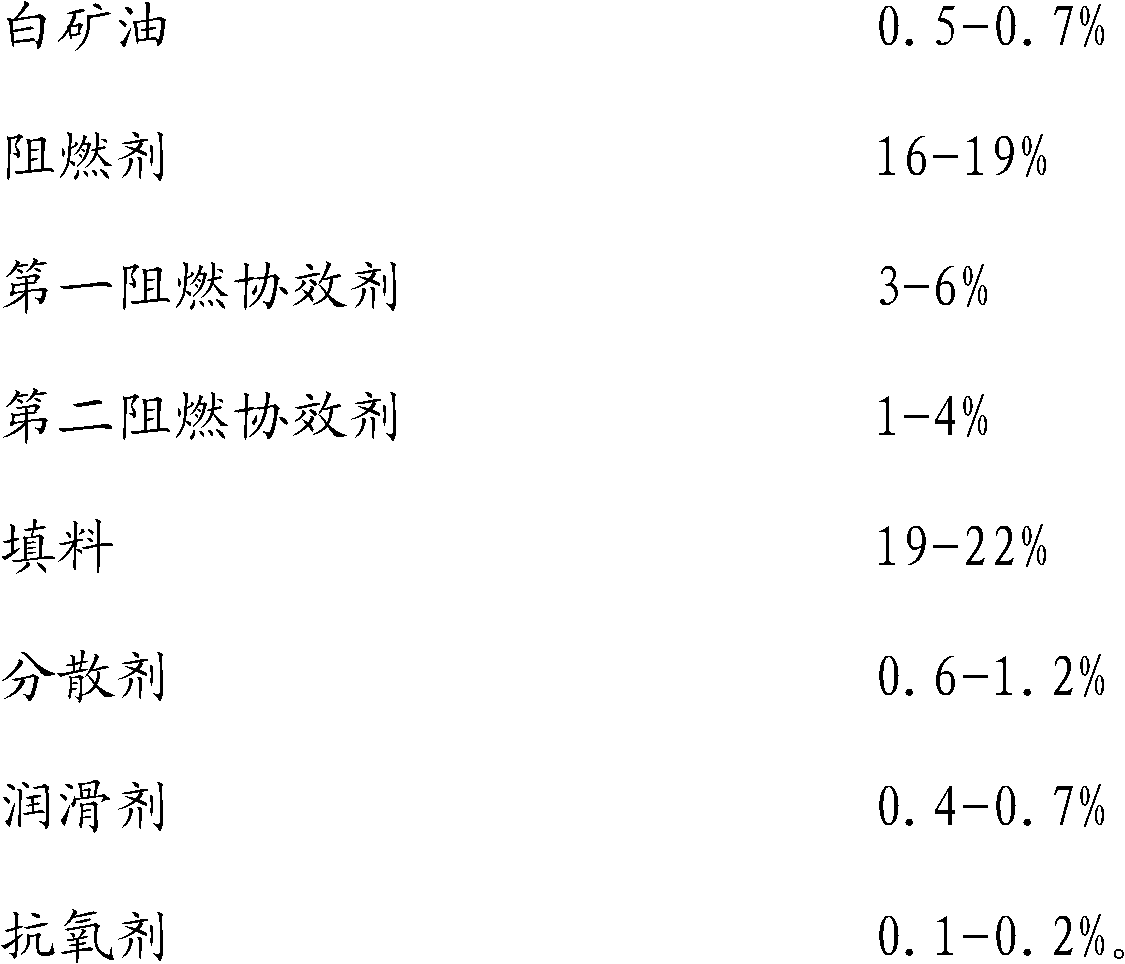

[0017] The high glow wire flame-retardant polypropylene material used for the heater housing in this embodiment is composed of the following components in terms of weight percentage:

[0018] 56.4% polypropylene, 0.5% white mineral oil, 16% flame retardant, 6% first flame retardant synergist, 1% second flame retardant synergist, 19% filler, 0.6% dispersant, 0.4% lubricant , Antioxidant 0.1%.

[0019] Its preparation method is as follows:

[0020] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0021] Step 2, mixing each component weighed evenly;

[0022] Step 3. Put the obtained mixed material in a twin-screw extruder, melt and react, extrude and granulate; the process conditions of the twin-screw extruder are: the temperature of the first zone is 180°C, the temperature of the second zone is 180°C, The temperature is 190°C, the temperature in the fourth zone is 190°C, the temperature in the fifth zone is 190°C, the temperature in the sixth z...

Embodiment 2

[0024] The high glow wire flame-retardant polypropylene material used for the heater housing in this embodiment is composed of the following components in terms of weight percentage:

[0025] 53.9% polypropylene, 0.6% white mineral oil, 17% flame retardant, 5% first flame retardant synergist, 2% second flame retardant synergist, 20% filler, 0.8% dispersant, 0.5% lubricant , Antioxidant 0.2%.

[0026] Its preparation method is as follows:

[0027] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0028] Step 2, mixing each component weighed evenly;

[0029] Step 3. Place the obtained mixture in a twin-screw extruder, melt and react, and extrude to pelletize; The temperature is 190°C, the temperature in the fourth zone is 200°C, the temperature in the fifth zone is 200°C, the temperature in the sixth zone is 190°C, the temperature in the seventh zone is 180°C, the temperature in the eighth zone is 180°C, the screw speed is 370r / min; the vacuum d...

Embodiment 3

[0031] The high glow wire flame-retardant polypropylene material used for the heater housing in this embodiment is composed of the following components in terms of weight percentage:

[0032] 51.6% polypropylene, 0.6% white mineral oil, 18% flame retardant, 4% first flame retardant synergist, 3% second flame retardant synergist, 21% filler, 1% dispersant, 0.6% lubricant , Antioxidant 0.2%.

[0033] Its preparation method is as follows:

[0034] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0035] Step 2, mixing each component weighed evenly;

[0036] Step 3. Place the obtained mixture in a twin-screw extruder, melt and react, and extrude to pelletize; The temperature is 210°C, the temperature in the fourth zone is 200°C, the temperature in the fifth zone is 190°C, the temperature in the sixth zone is 190°C, the temperature in the seventh zone is 180°C, the temperature in the eighth zone is 180°C, the screw speed is 380r / min; the vacuum deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com