Preparation method of organic silicon-phosphorus synergistic flame retardant

A synergistic flame retardant and silicone technology, applied in the field of flame retardants, can solve problems such as inability to effectively exert the flame retardant effect, excessive addition of flame retardants, poor compatibility between flame retardants and substrates, and achieve The effect of improving synthesis efficiency, improving affinity, and enhancing flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

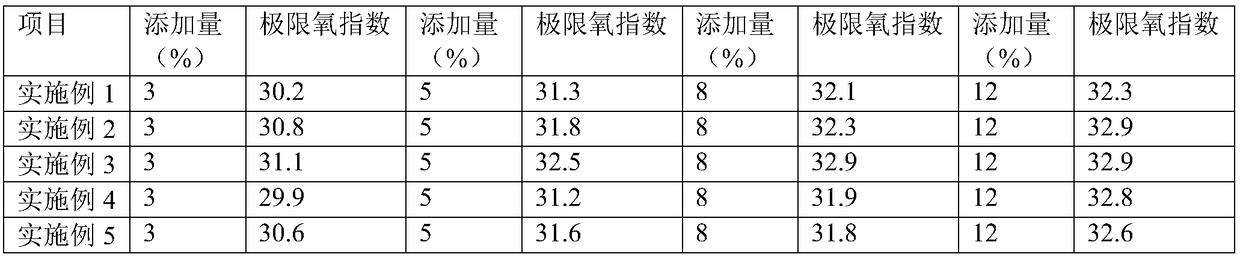

Examples

Embodiment 1

[0031] A preparation method of an organosilicon-phosphorus synergistic flame retardant, said preparation method comprising the following steps:

[0032] (1) Preparation of polyhydrogen silsesquioxane: trichlorosilane is hydrolyzed in an aqueous solution under the action of a catalyst to obtain polyhydrogen silsesquioxane. The specific steps are as follows:

[0033] (1.1) Preliminary condensation: Add 100 parts of chloroform, 1 part of catalyst and 15 parts of distilled water into the reaction kettle, then stir the solution at high speed to form an emulsion, then lower the temperature to -20°C, and slowly add trichlorosilane dropwise 20 parts, after the dropwise addition, the temperature was raised to room temperature, and the stirring reaction was continued for 8 hours;

[0034] (1.2) Hydrochloric acid removal: then add 15 parts of triethylamine therein, continue to react for 2 hours, stop reaction then, filter and remove the triethylamine hydrochloride salt that reaction gene...

Embodiment 2

[0040] A preparation method of an organosilicon-phosphorus synergistic flame retardant, said preparation method comprising the following steps:

[0041] (1) Preparation of polyhydrogen silsesquioxane: trichlorosilane is hydrolyzed in an aqueous solution under the action of a catalyst to obtain polyhydrogen silsesquioxane. The specific steps are as follows:

[0042] (1.1) Preliminary condensation: Add 100 parts of chloroform, 5 parts of catalyst and 15 parts of distilled water into the reaction kettle, then stir the solution at high speed to form an emulsion, then lower the temperature to -20°C, and slowly add trichlorosilane dropwise 35 parts, after the dropwise addition, the temperature was raised to room temperature, and the stirring reaction was continued for 12 hours;

[0043] (1.2) Hydrochloric acid removal: then add 15 parts of triethylamine therein, continue to react for 5 hours, stop reaction then, filter and remove the triethylamine hydrochloride salt that reaction ge...

Embodiment 3

[0049] A preparation method of an organosilicon-phosphorus synergistic flame retardant, said preparation method comprising the following steps:

[0050] (1) Preparation of polyhydrogen silsesquioxane: trichlorosilane is hydrolyzed in an aqueous solution under the action of a catalyst to obtain polyhydrogen silsesquioxane. The specific steps are as follows:

[0051] (1.1) Preliminary condensation: Add 100 parts of chloroform, 3 parts of catalyst and 15 parts of distilled water into the reaction kettle, then stir the solution at high speed to form an emulsion, then lower the temperature to -20°C, and slowly add trichlorosilane dropwise 30 parts, after the dropwise addition, the temperature was raised to room temperature, and the stirring reaction was continued for 10 hours;

[0052] (1.2) Hydrochloric acid removal: then add 15 parts of triethylamine therein, continue to react for 3 hours, stop reaction then, filter and remove the triethylamine hydrochloride salt that reaction ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com