Concerted catalysis flame-retardant metal complex containing P/N/Si/S/Ni and preparation method of complex

A metal complex and synergistic catalysis technology, applied in the field of intumescent metal flame retardants, can solve the problems of poor flame retardant efficiency of intumescent organic flame retardants, toxic fumes and large usage of halogen flame retardants , to achieve the effect of simple and easy control of the reaction process, improved flame retardant effect, mild and stable synthesis process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a metal complex containing P / N / Si / S / Ni synergistically catalyzed and flame-retardant is:

[0039] (1) In 30mL of dichloromethane, first add 2.3mL (10mmol) of 3-aminopropyltriethoxysilane, then slowly add 4.1mL (23mmol) of diphenylphosphorous chloride, then slowly add 3.1 mL (22 mmol) of triethylamine; after stirring overnight at room temperature, a light yellow suspension was obtained, which was filtered through a sand core to remove the triethylamine hydrochloride solid to obtain a light yellow liquid, which was rotary evaporated to remove dichloromethane to obtain Solid crude product; finally, it was washed with tetrahydrofuran, recrystallized from dichloromethane and dried in vacuo to obtain a pale white solid, namely intermediate I (yield 89%); melting point was 66-68°C.

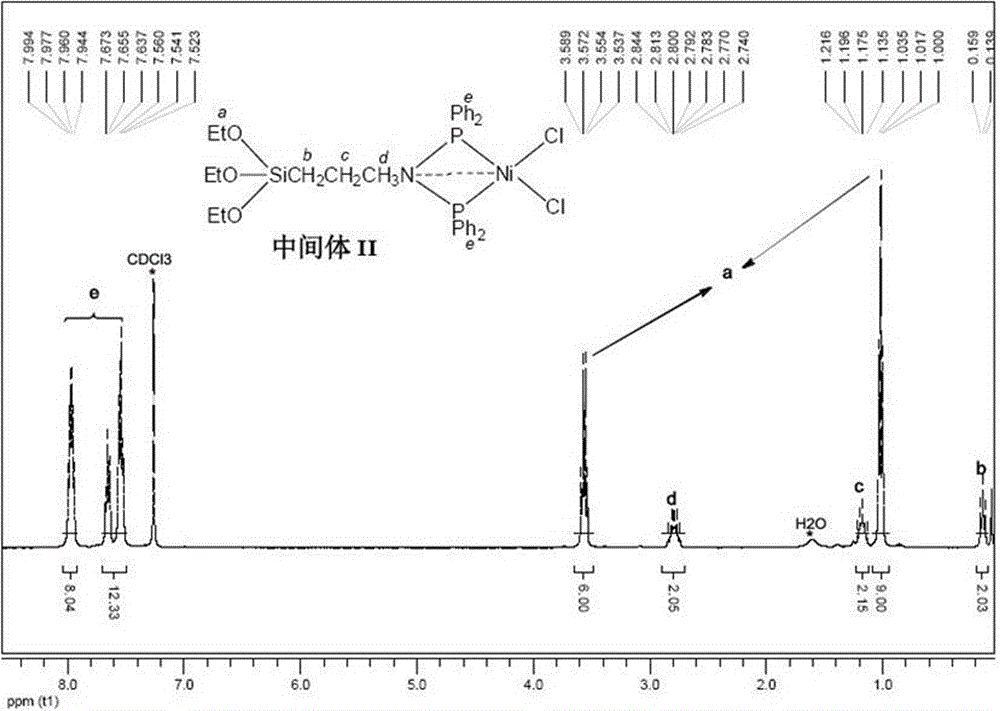

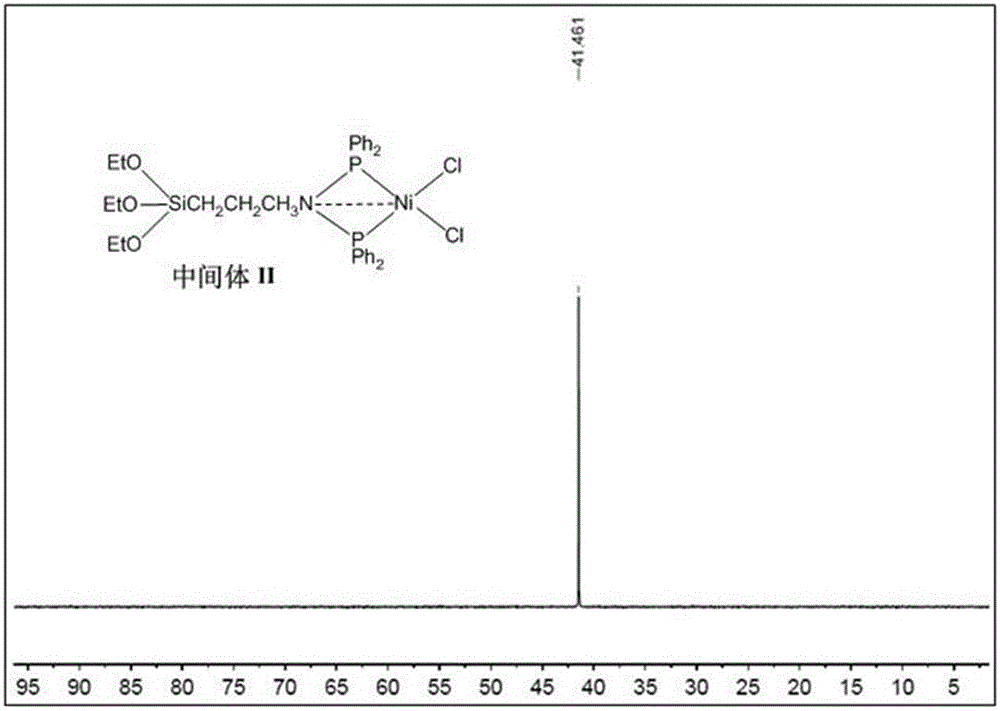

[0040] (2) In a mixed solvent of 35mL absolute ethanol + 10mL dichloromethane, first add 1.19g (5.0mmol) of nickel dichloride hexahydrate and stir vigorously until complete...

Embodiment 2

[0045] A preparation method of a metal complex containing P / N / Si / S / Ni synergistically catalyzed and flame-retardant is:

[0046] (1) In 30mL of dichloromethane, first add 2.3mL (10mmol) of 3-aminopropyltriethoxysilane, then slowly add 4.1mL (23mmol) of diphenylphosphorous chloride, then slowly add 3.1 mL (22 mmol) of triethylamine; after stirring overnight at room temperature, a light yellow suspension was obtained, which was filtered through a sand core to remove the triethylamine hydrochloride solid to obtain a light yellow liquid, which was rotary evaporated to remove dichloromethane to obtain Solid crude product; finally, it was washed with tetrahydrofuran, recrystallized from dichloromethane and dried in vacuo to obtain a pale white solid, which is intermediate I (yield 88%).

[0047] (2) In a mixed solvent of 35mL absolute ethanol + 10mL dichloromethane, first add 1.10g (5.0mmol) of anhydrous nickel dibromide and stir vigorously until completely dissolved, then add 3.25g...

Embodiment 3

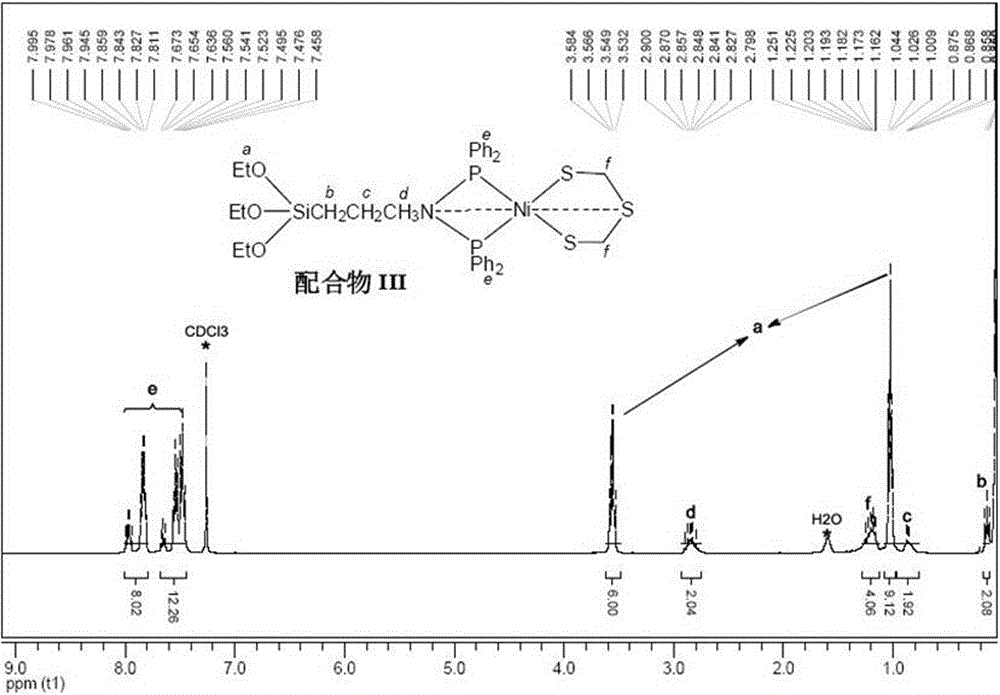

[0050] A preparation method of a metal complex containing P / N / Si / S / Ni synergistically catalyzed and flame-retardant is:

[0051] (1) In 30mL of dichloromethane, first add 2.3mL (10mmol) of 3-aminopropyltriethoxysilane, then slowly add 4.1mL (23mmol) of diphenylphosphorous chloride, then slowly add 3.1 mL (22 mmol) of triethylamine; after stirring overnight at room temperature, a light yellow suspension was obtained, which was filtered through a sand core to remove the triethylamine hydrochloride solid to obtain a light yellow liquid, which was rotary evaporated to remove dichloromethane to obtain Solid crude product; finally, it was washed with tetrahydrofuran, recrystallized from dichloromethane and dried in vacuo to obtain a pale white solid, which is intermediate I (91% yield).

[0052] (2) In a mixed solvent of 35mL anhydrous methanol + 10mL dichloromethane, first add 1.34g (5.0mmol) of anhydrous nickel diiodide and stir vigorously until completely dissolved, then add 3.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com