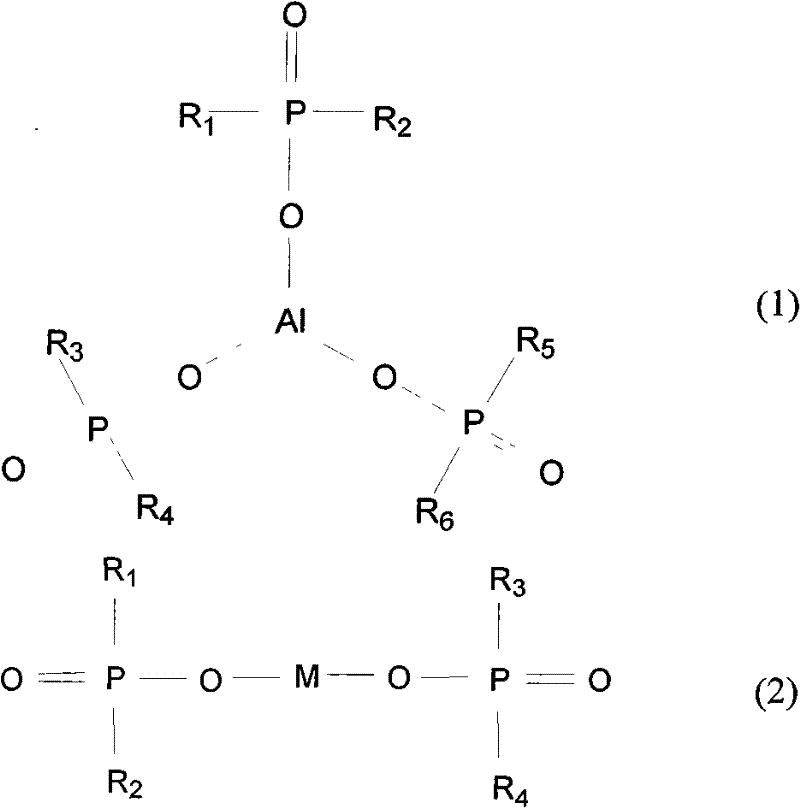

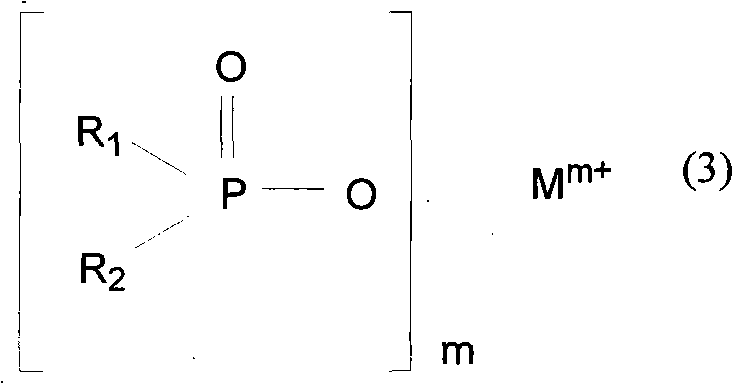

Partially alkylated phosphinic acid nonalkali metal salt and preparing method and application thereof

A technology of alkylating phosphinic acid and alkali metal salt, applied to the application of partially alkylated phosphinic acid non-alkali metal salt in polymer flame retardancy, partially alkylated phosphinic acid non-alkali metal salt and its In the field of preparation, it can solve the problems of high requirements for reaction equipment and cumbersome steps, and achieve the effect of simple equipment requirements, simple process and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 600g of aluminum hypophosphite into a 5L reactor filled with 2.5L of deionized water, stir and disperse evenly. Weigh 10g of ammonium persulfate and add water to configure an initiator solution with a mass percent solubility of 3%, and put the initiator solution on the reaction kettle. Heating so that the temperature rises to 105°C after 30 minutes, start filling isobutene gas, and start adding the initiator solution dropwise when the pressure is stabilized at 0.01 MPa, and add it uniformly within 8 hours. 10 minutes after the initiator was added dropwise, stop aerating and turn off the heating device, stop stirring after 30 minutes, open the reaction kettle, filter the obtained solid-liquid mixture, and dry in an oven at 105°C for 5 hours to obtain 1198.1g of white fluid powder. Molecular formula H 2 (C 4 h 9 ) 4 P 3 o 6 Al: phosphorus content is 20.8%; X-ray electron spectrum: phosphorus content is 20.6%.

Embodiment 2

[0036]Weigh 600g of aluminum hypophosphite into a 5L reactor filled with 2.5L of deionized water, stir and disperse evenly. Weigh 8g of ammonium persulfate and add water to configure an initiator solution with a mass percentage solubility of 3%, and put the initiator solution on the reaction kettle. Heating so that the temperature rises to 65°C after 30 minutes, start filling isobutylene gas, and start adding the initiator solution dropwise when the pressure is stabilized at 0.01 MPa, and add it uniformly within 8 hours. 10 minutes after the initiator was added dropwise, stop aerating and turn off the heating device, stop stirring after 30 minutes, open the reaction kettle, filter the obtained solid-liquid mixture, and dry in an oven at 105°C for 5 hours to obtain 902.3g of white fluid powder. Molecular formula H 4 (C 4 h 9 ) 2 P 3 o 6 Al: phosphorus content 27.8%; X-ray electron spectrum: phosphorus content 27.7%.

Embodiment 3

[0038] Weigh 600g of magnesium hypophosphite and add it into a 5L reaction kettle filled with 2.5L of deionized water, stir and disperse evenly. Weigh 0.6g of 2,2'-azobis(2-amidinopropane) dihydrochloride and add water to configure an initiator solution with a mass percent solubility of 3%, and put the initiator solution on the reaction kettle. Heat to make the temperature rise to 100°C after 30 minutes, start to fill with ethylene gas, and start dropping the initiator solution when the pressure is stabilized at 0.1 MPa, and add it uniformly within 8 hours. 10 minutes after the initiator was added dropwise, stop aerating and turn off the heating device, stop stirring after 30 minutes, open the reaction kettle, filter the obtained solid-liquid mixture, and dry in an oven at 105°C for 5 hours to obtain 930.5g of white fluid powder. Molecular formula H(C 2 h 5 ) 3 P 2 o 4 Mg: phosphorus content 26.1%; X-ray electron spectrum: phosphorus content 25.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com