Rigid polyurethane foam with high flame retardance and preparation method of rigid polyurethane foam

A technology of rigid polyurethane and flame-retardant polyester, which is applied in the field of polyurethane foam, can solve the problems of poor flame-retardant effect, affecting the physical properties of polyurethane foam, and high proportion of flame retardants, so as to achieve improved flame-retardant effect, excellent compressive strength and The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

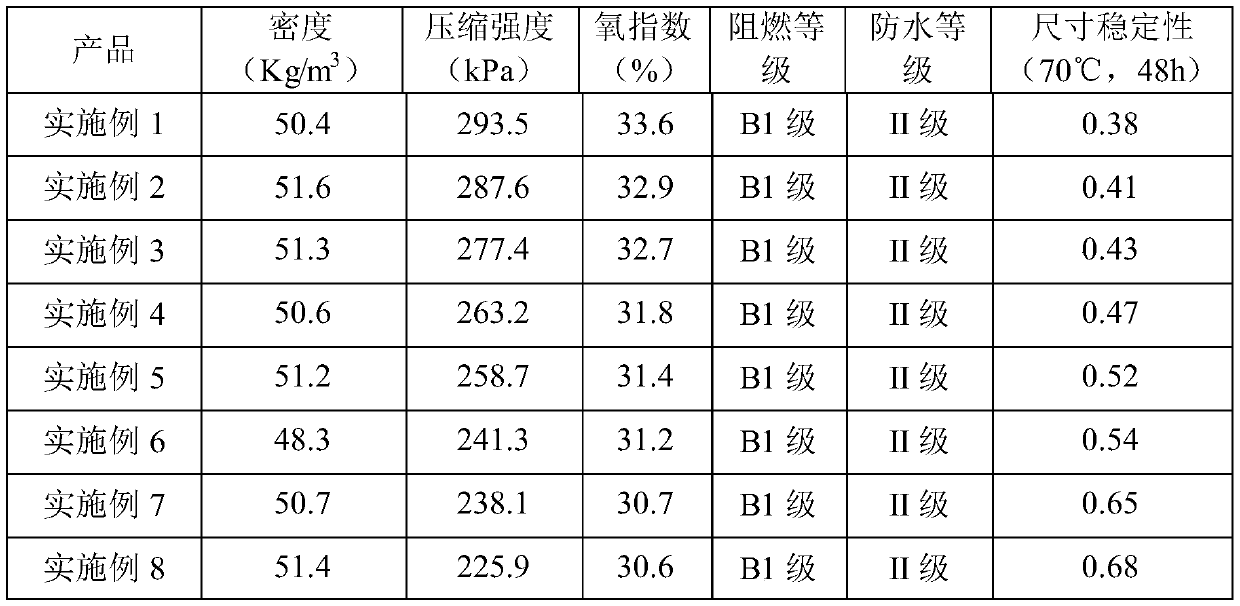

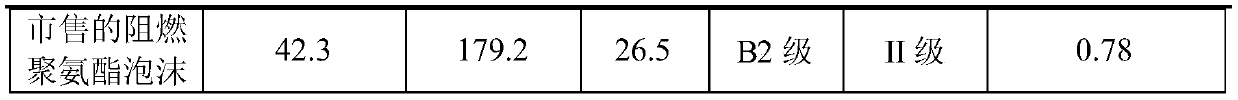

Examples

preparation example Construction

[0038] In a second aspect, the present invention provides a method for preparing a high flame-retardant rigid polyurethane foam as described in the first aspect, comprising the steps of:

[0039] (1) Flame-retardant polyether polyol A, flame-retardant polyether polyol B, flame-retardant polyester polyol C, polyether polyol D, antioxidant, anti-hydrolysis stabilizer, foam stabilizer, water, catalyst A , Catalyst B, Catalyst C, flame retardant, blowing agent and auxiliary agent are mixed uniformly according to the proportion to prepare A component;

[0040] (2) The A component and the B component are sprayed on the base material by a spraying machine to prepare polyurethane foam.

[0041] In the embodiment of the present invention, the step (1) specifically includes: after uniformly mixing the auxiliary agent, catalyst A, and catalyst B, adding flame-retardant polyether polyol A, flame-retardant polyether polyol B, flame-retardant polyol Ester polyol C, polyether polyol D, anti...

Embodiment 1

[0049] The preparation method of the highly flame-retardant rigid polyurethane foam provided by the present embodiment comprises the following steps:

[0050] (1) Weigh the following raw materials in parts by weight: 47.2 parts of flame-retardant polyether polyol A, 39.4 parts of flame-retardant polyether polyol B, 31.2 parts of flame-retardant polyester polyol C, polyether 6.2 parts of polyol D, 2.5 parts of antioxidant TPP, 1.85 parts of monomeric carbodiimide, 2.32 parts of silicone foam stabilizer AK-8832, 4.3 parts of water, 3.6 parts of N,N-dimethylcyclohexylamine , 2.4 parts of ethylenediamine, 2.6 parts of dibutyltin dilaurate, 27.5 parts of triethyl phosphate, 42.6 parts of 1,1,1,3,3-pentafluorobutane, 4.0 parts of additives; the additives, N, After mixing N-dimethylcyclohexylamine and ethylenediamine evenly, add flame retardant polyether polyol A, flame retardant polyether polyol B, flame retardant polyester polyol C, polyether polyol D, antioxidant Agent TPP, monom...

Embodiment 2

[0053] The preparation method of the highly flame-retardant rigid polyurethane foam provided by the present embodiment comprises the following steps:

[0054] (1) Weigh the following raw materials in parts by weight: 52.3 parts of flame-retardant polyether polyol A, 38.6 parts of flame-retardant polyether polyol B, 32.5 parts of flame-retardant polyester polyol C, polyether polyol 6.5 parts of alcohol D, 2.4 parts of antioxidant TPP, 2.4 parts of monomeric carbodiimide, 2.8 parts of silicone foam stabilizer AK-8832, 4.5 parts of water, 3.5 parts of N,N-dimethylcyclohexylamine, 2.6 parts of ethylenediamine, 2.6 parts of dibutyltin dilaurate, 28 parts of triethyl phosphate, 35 parts of 1,1,1,3,3-pentafluorobutane, 3 parts of additives; -After mixing dimethylcyclohexylamine and ethylenediamine evenly, add flame-retardant polyether polyol A, flame-retardant polyether polyol B, flame-retardant polyester polyol C, polyether polyol D, and antioxidant TPP, monomeric carbodiimide, sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com