Novel environment-friendly flame-retardant modified unsaturated polyester resin and preparation method thereof

A polyester resin and unsaturated technology, which is applied in the field of new environmentally friendly flame-retardant modified unsaturated polyester resin and its preparation, can solve the problems of achieving a balance between environmental protection and flame-retardant effect, and achieve the effect of improving flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The matrix resin with flame retardant effect was synthesized in a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser.

[0037] Main raw materials: methyl propylene glycol, diethylene glycol, maleic anhydride, tetrabromophthalic anhydride, tribromoneopentyl alcohol, chlorostyrene, styrene accessories;

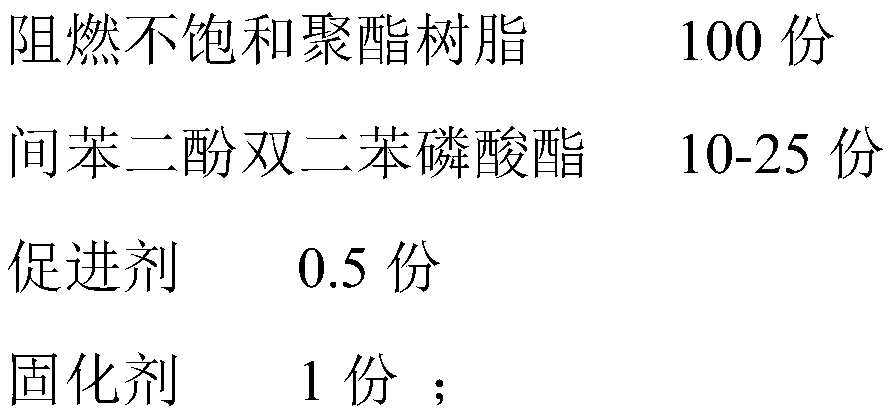

[0038] The ratio of each raw material is as follows: (the ratio is the consumption ratio, that is, the percentage of the weight of the material to 100 parts of the finished flame-retardant matrix resin)

[0039]

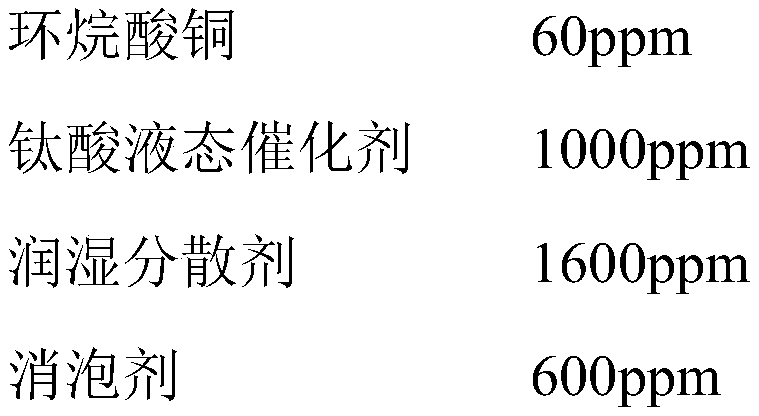

[0040] Excipients: copper naphthenate, titanic acid liquid catalyst, compatible wetting and dispersing agent, defoamer (silane)

[0041] ppm is one millionth of the total weight of the resin

[0042]

[0043]

[0044] The key points of the synthesis process: process temperature rise, high positive pressure catalytic reaction in the front stage, and ultimate negative pressure evacuation reaction in the latter stage

[0045]...

Embodiment 2

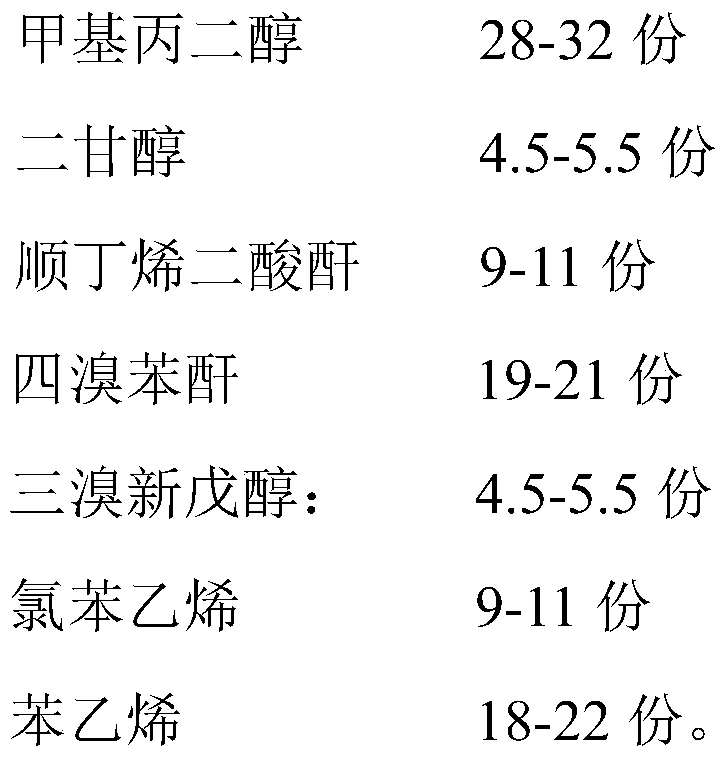

[0061] The flame retardant unsaturated polyester resin of the present embodiment comprises the following components in parts by weight:

[0062]

[0063] The flame retardant unsaturated polyester resin also includes by weight parts:

[0064]

[0065] Inhibitor: TBC tris(2,3-dibromopropyl)isocyanurate 150ppm.

[0066] The preparation method is the same as in Example 1.

Embodiment 3

[0068] The flame retardant unsaturated polyester resin comprises the following components in parts by weight:

[0069]

[0070] The flame retardant unsaturated polyester resin also includes by weight parts:

[0071]

[0072] Inhibitor: TBC tris(2,3-dibromopropyl)isocyanurate 150ppm.

[0073]The preparation method is the same as in Example 1.

[0074] Blending modification of unsaturated flame retardant matrix resin by adding new flame retardant in different proportions

[0075] Resorcinol bis-diphenyl phosphate is a high-molecular-weight organophosphorus flame retardant, which appears to be a clear liquid; it has a high phosphorus content of 10.8%. It has the characteristics of high flame retardancy, low addition amount, and little influence on the physical properties of the finished product. It has dual functions of flame retardant and plasticizing, which can make the flame retardant completely non-halogenated, improve the flow processing performance and reduce ablat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com