Sealing strip butt-joint thin slice rubber material and preparation method thereof, and sealing strip butt-joint thin slice rubber sheet processing method and processing device

A processing method and technology of a processing device, which are applied in the field of sealing strip butting sheet rubber and its preparation, can solve the problems of reduced production qualification rate, inconvenient storage, short validity period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment relates to a sealing strip butt joint sheet compound and its preparation.

[0043] The raw material components and proportions shown in the following table are used to prepare the sealing strip butt joint sheet compound:

[0044]

[0045]

[0046] Explanation: "EPDM K6950C" in the above table indicates the use of EPDM rubber 6950C produced by LANXESS, Germany; "accelerator BZ-75" indicates the use of accelerator BZ with a mass content of 75% active ingredients , "-75" after other accelerators has the same meaning; "sulfur-80" indicates the use of sulfur with an active ingredient mass content of 80%.

[0047] According to the ratio of the raw material components in the above table, adopt the traditional rubber one-step mixing process to prepare the sealing strip butt joint sheet rubber. Concrete preparation steps are as follows:

[0048] First put the raw material components EPDM rubber, zinc oxide and stearic acid into the internal mixer and knea...

Embodiment 2

[0050] This embodiment relates to a processing method for preparing a sealing strip butt joint sheet film from the sealing strip butt joint sheet rubber material of the first embodiment.

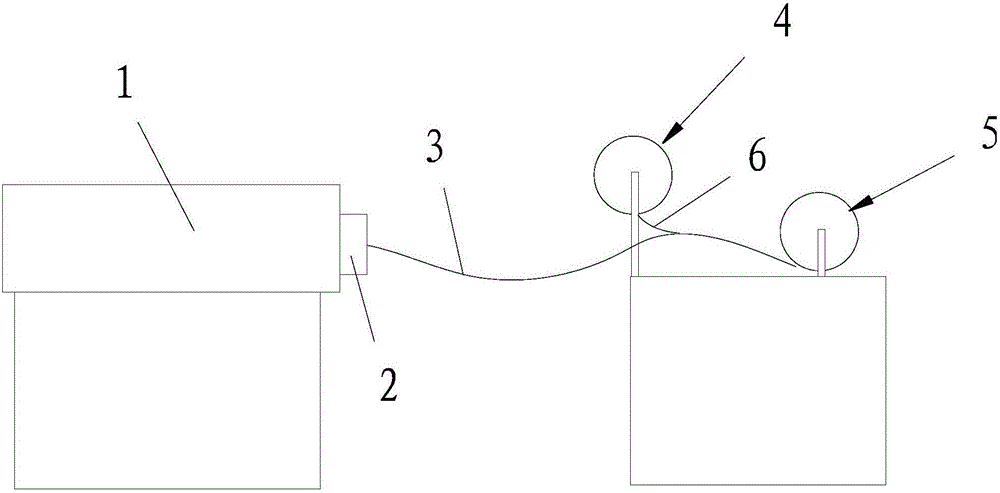

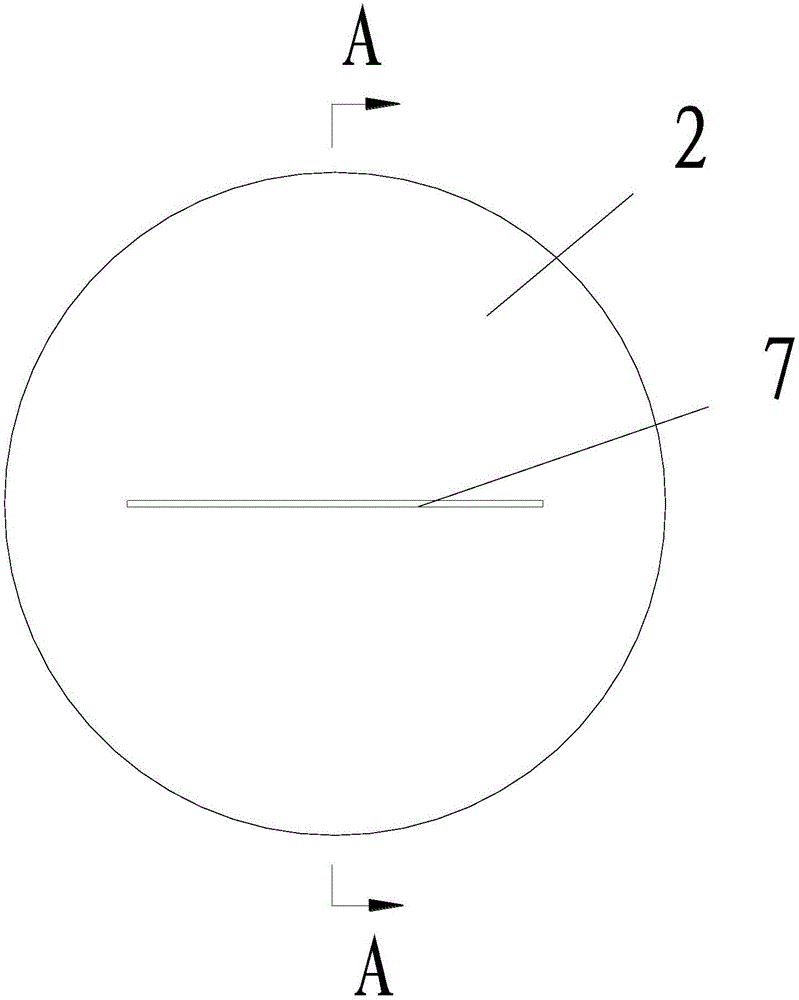

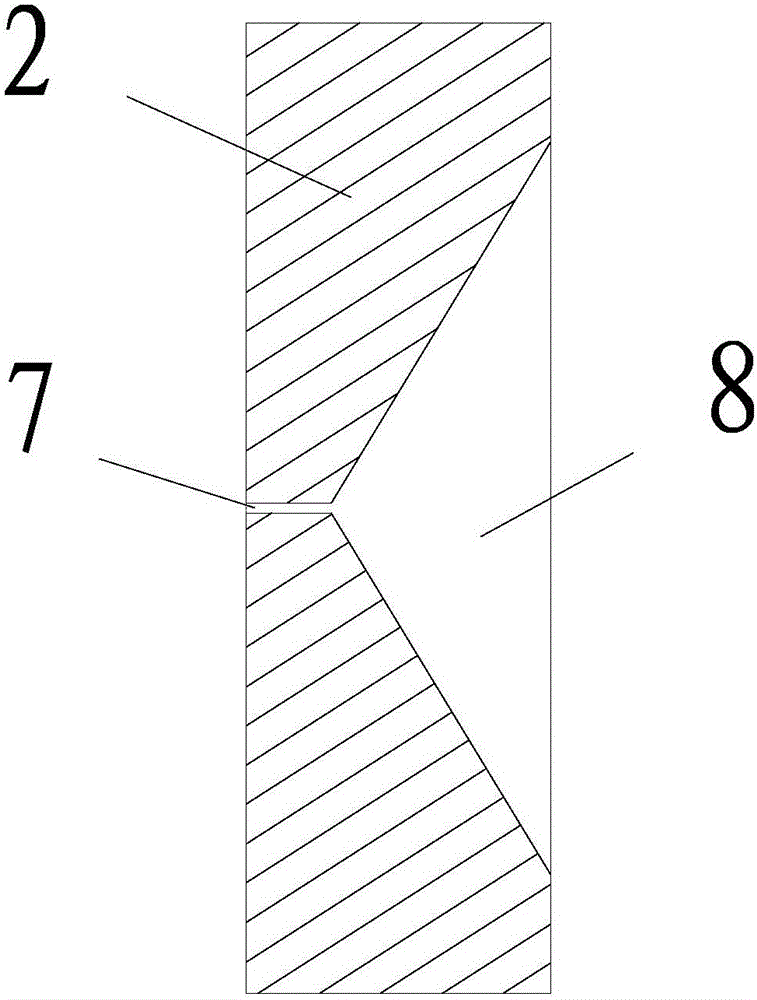

[0051] The processing method is figure 1 The sealing strip butt joint thin film processing device shown is carried out, and the sealing strip butt joint thin film film processing device includes an extruder 1, and the extruder 1 can adopt a single-screw extruder with a screw diameter of 60 mm. A molding die 2 is connected to the extrusion head, and the molding die 2 has a film outlet. The sealing strip butt sheet rubber material passes through the extruder 1 and comes out from the film outlet of the molding die 2 to obtain a continuous film with a fixed thickness. The sealing strip is docked with the thin film 3, after the film laying mechanism 3 installed downstream of the extruder 1 is connected to the surface of the thin film, the isolation film 6 is laid, and finally the sealing strip is...

Embodiment 3

[0062] This embodiment relates to the performance verification of the sealing strip butt joint sheet obtained from the sealing strip butt joint sheet compound of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com