Color filter and manufacturing method thereof

A technology of color filters and color filter layers, which is applied in the direction of filters, optics, optical components, etc., and can solve problems such as complex flat layer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

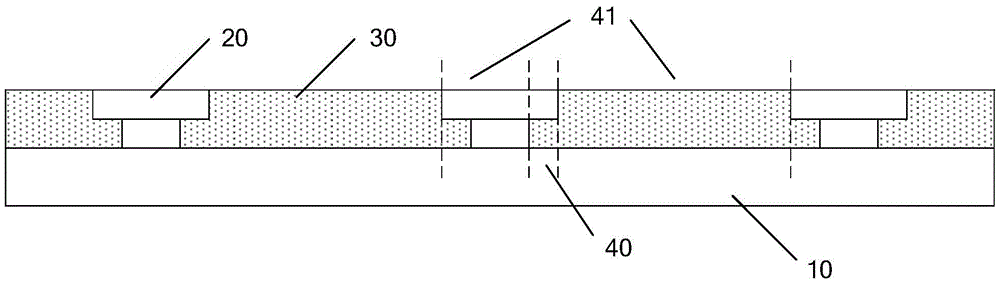

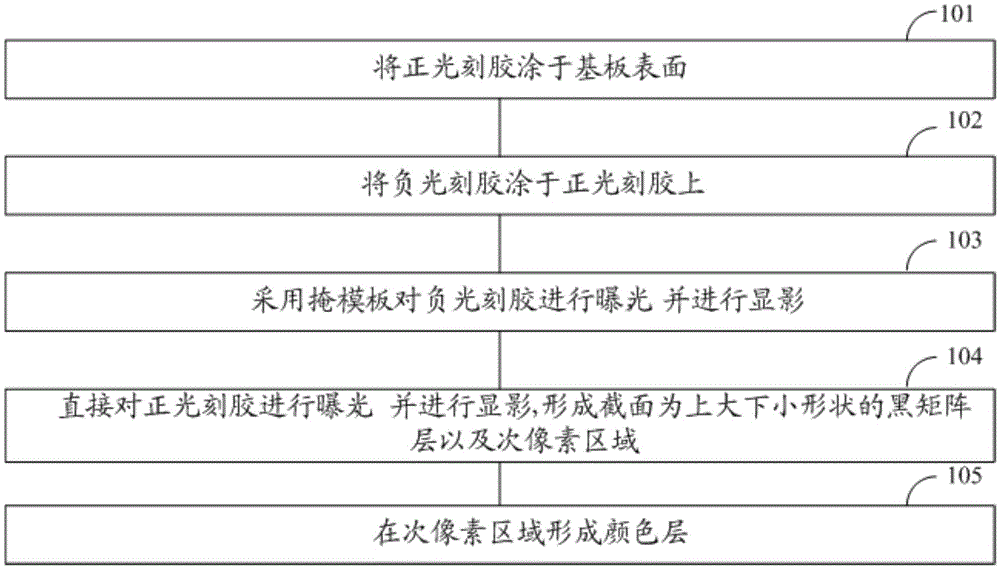

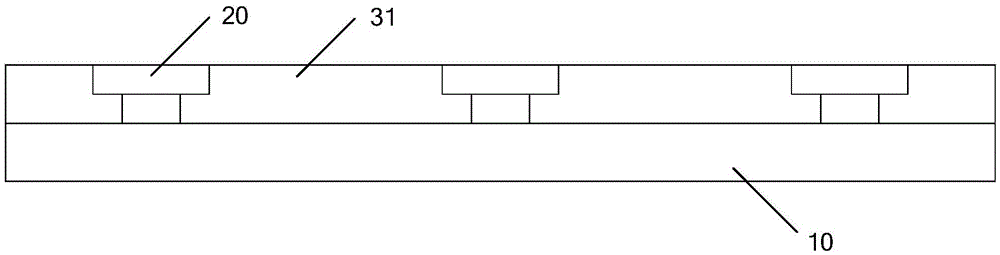

[0025] An embodiment provided by this embodiment is a color filter, such as figure 1 As shown, it includes the black matrix layer 20 formed on the substrate 10, and the color filter layer 30 formed on the sub-pixel area defined by the black matrix layer 20, wherein the cross section of the black matrix layer 20 is in the shape of a large top and a small bottom, There is an overlapping area 40 with the color filter layer 30 whose cross-section is large at the bottom and small at the top, and the film thickness of the overlapping area is the same as that of the non-overlapping area 41 .

[0026] Depend on figure 1 It can be seen that since the overlapping area 40 and the non-overlapping area 41 have the same film thickness, there is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com