High-voltage distribution cabinet of electric vehicle

A technology for high-voltage power distribution and electric vehicles, which is applied in substation/power distribution device shells, electrical components, panel/switch station circuit devices, etc., and can solve the problem of low protection level of high-voltage boxes, imperfect protection measures, and incomplete circuit monitoring systems and other problems, to improve the waterproof performance, prevent the circuit from overheating and burn out the resistors and components, and achieve the effect of overall beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

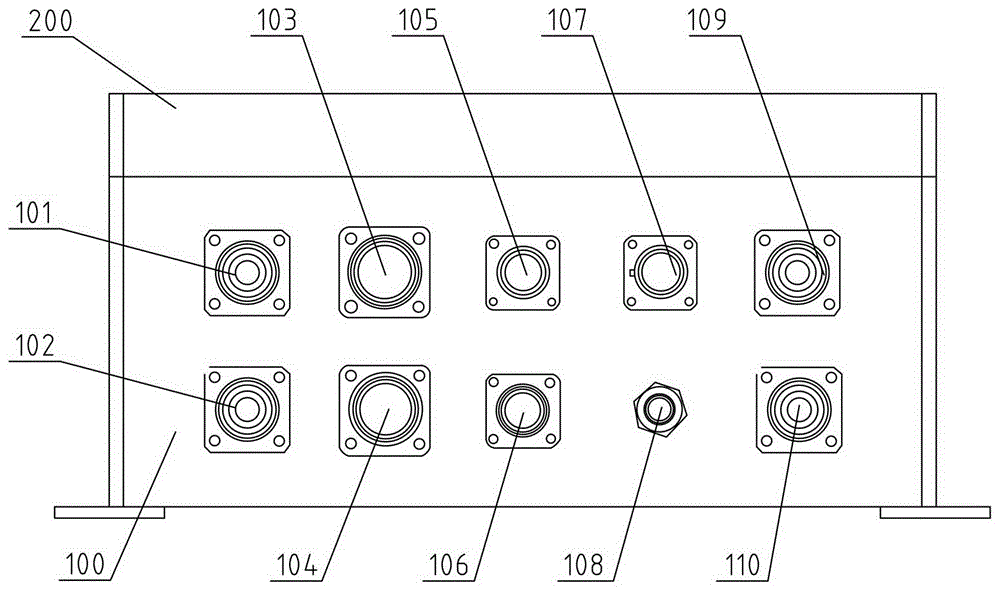

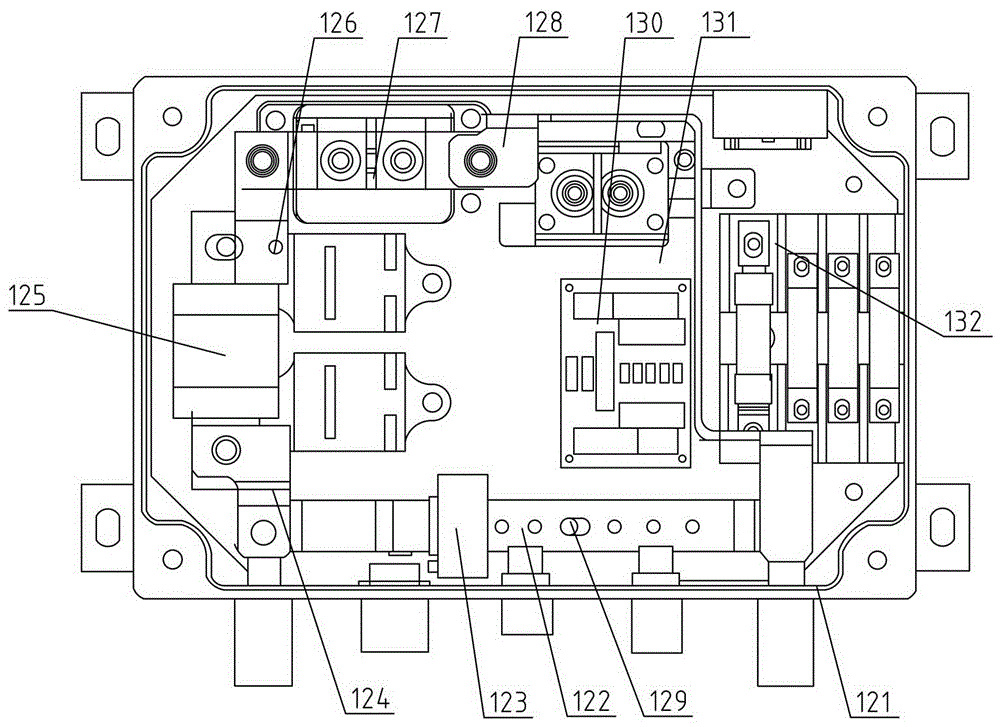

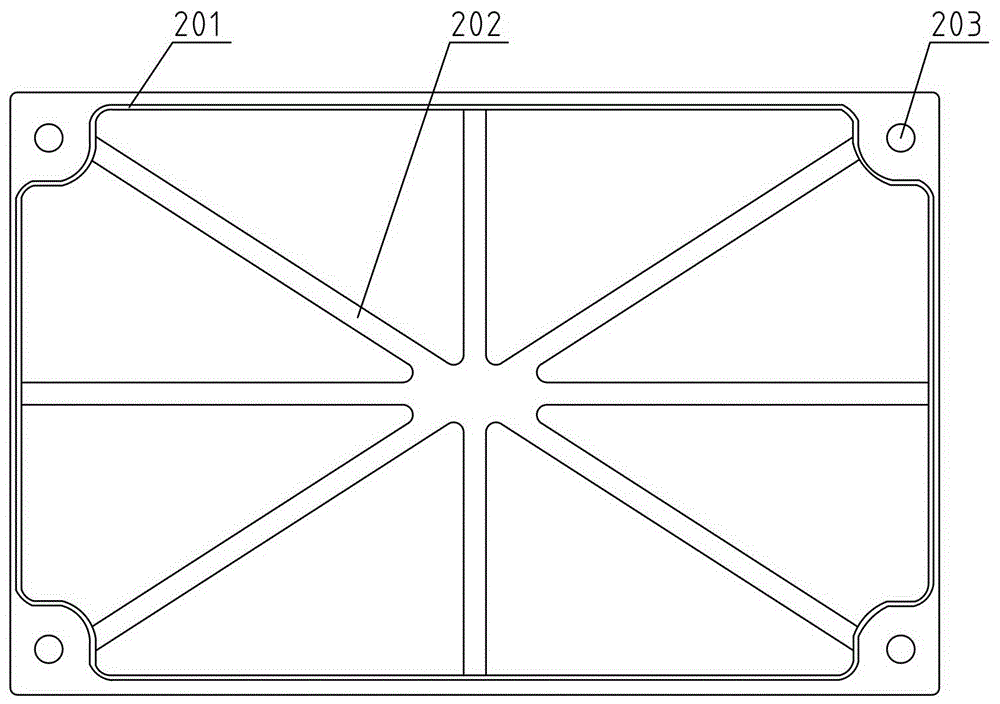

[0033] Such as Figure 1 to Figure 4 As shown, a high-voltage distribution box for an electric vehicle of the present invention includes a box body and a box cover. The box body is provided with a concave cavity, and a circuit board, a current detector, and a fuse are installed in the cavity of the box body. , thermistors, relays, copper bars, wires, the outer wall of the box is provided with a plurality of electrically connected connectors, the opening end surface of the concave cavity of the box is provided with bosses in the circumferential direction, and the box The cover is provided with a groove engaged with the boss, and a rubber ring is arranged in the groove of the case cover.

[0034] Specifically, the present invention includes a box body 100, a casting box cover 200, and the box body 100 is provided with a battery positive connector 101, a battery negative connector 102, an electric defrosting connector 103, a vehicle charging connector 104, and an insulation detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com