Batch machining workbench suitable for CNC machine tool and detection machining method

A technology of batch processing and processing methods, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inability to remove workpiece size, product quality decline, defect rate increase, etc., to achieve good foolproof effect, improve Quality and the effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

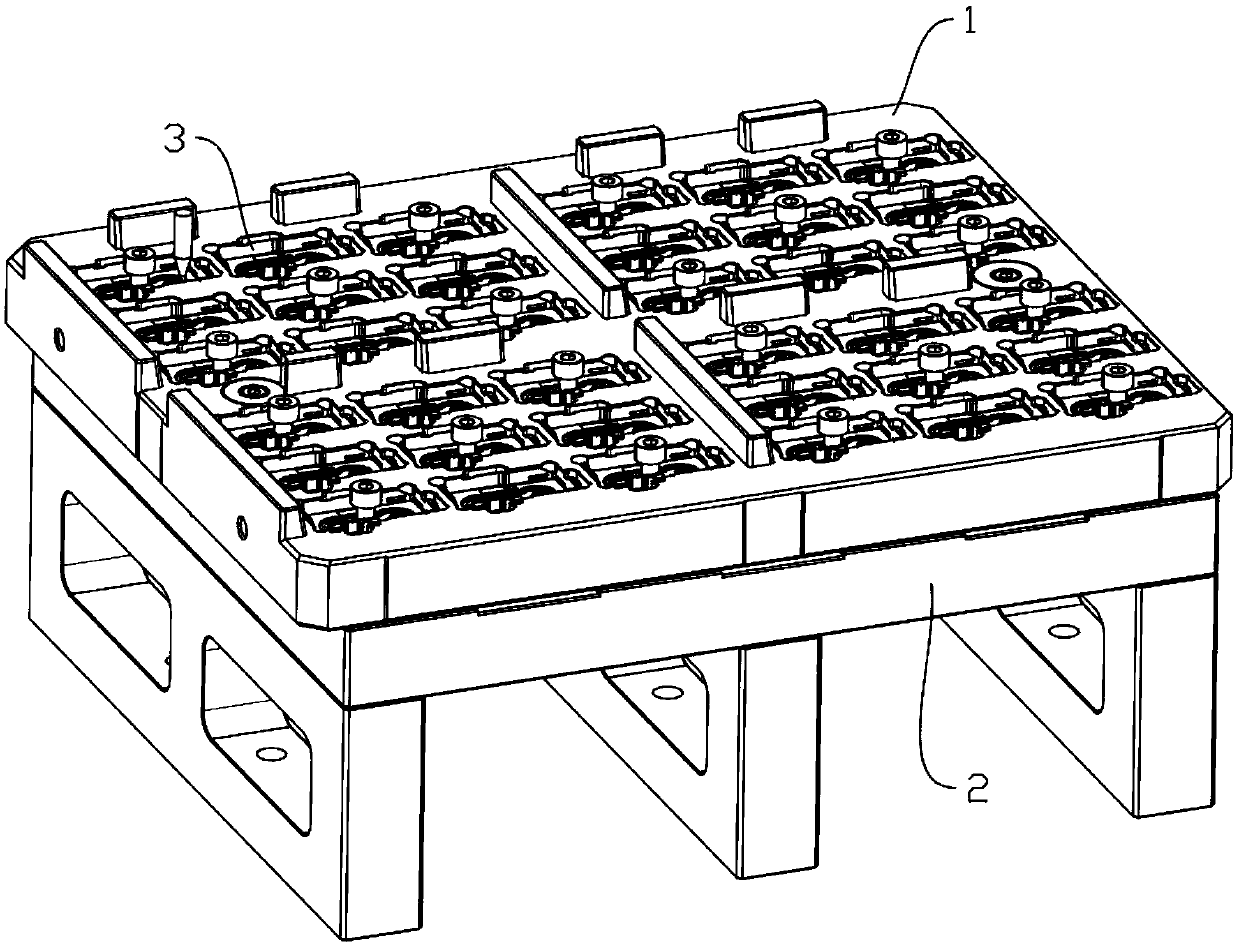

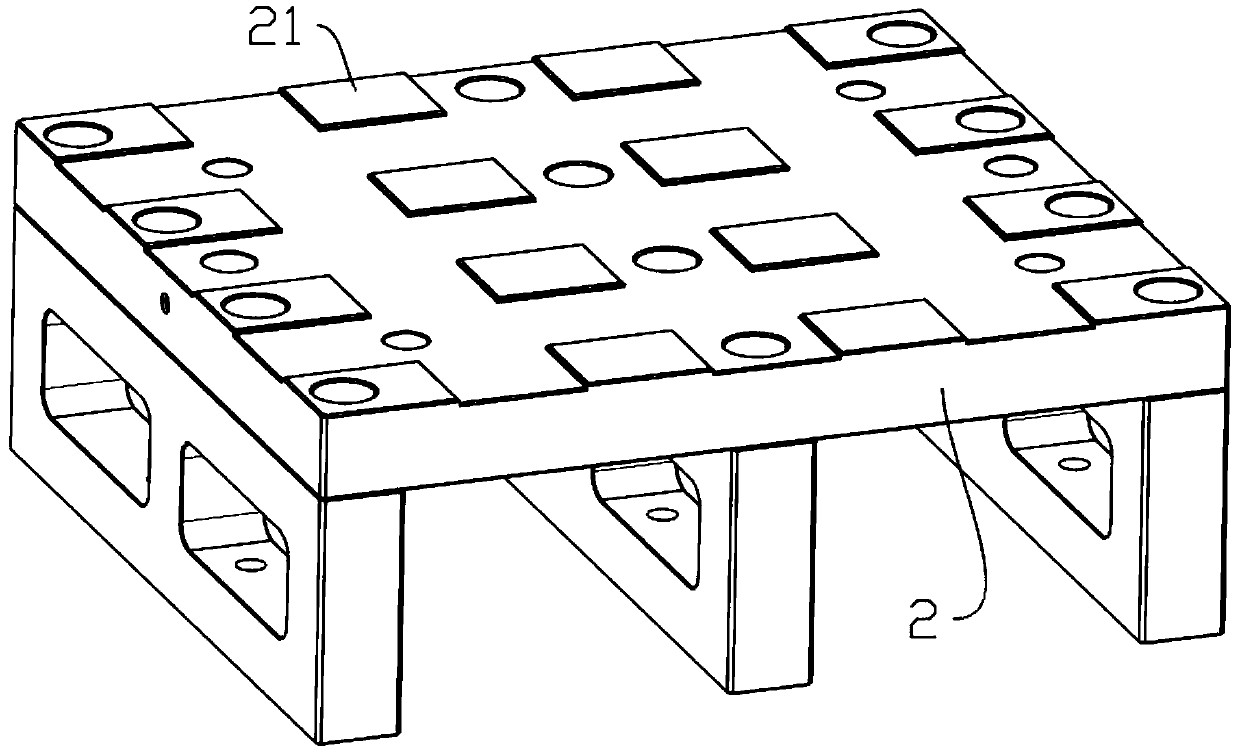

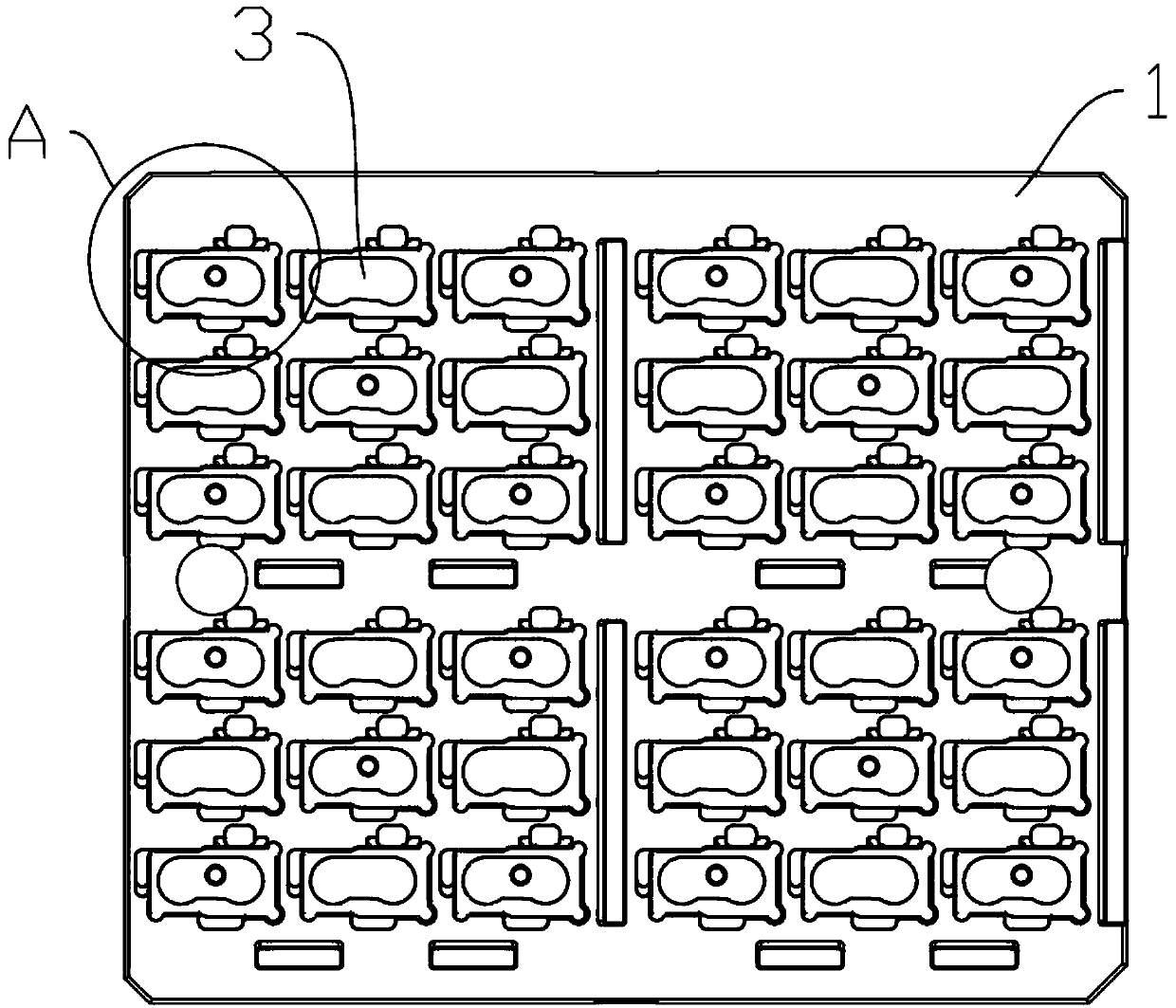

[0026] Examples, see Figure 1 to Figure 5 , a batch processing workbench suitable for CNC machine tools provided in this embodiment includes a workpiece positioning and placing plate 1 and a machine tool coupling seat 2, and the workpiece positioning and placing plate 1 is fixedly connected to the upper surface of the machine tool coupling seat 2 On the upper surface of the workpiece positioning and placing plate 1, a plurality of acupoints 3 for placing workpieces are evenly arranged and sequentially arranged, and the outer ring of the acupoints 3 is provided with a plurality of pick-up slots 31. There is a feeding inclined surface 32 on the inner wall. The acupoints 3 are evenly spaced and sequentially arranged to facilitate the batch processing of workpieces and make the processing more efficient. The setting of the feeding slope 32 and the picking groove 31 facilitates the taking and discharging of the workpieces. The structures and realized functions of the multiple acu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com