Reflux device for controlling film thickness of multi-gap pole piece and control method thereof

A reflow device and multi-gap technology, which is applied to the device for coating liquid on the surface, electrode manufacturing, electrode collector coating, etc., can solve the problems of uncontrollable thickness of pole pieces, potential safety hazards, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

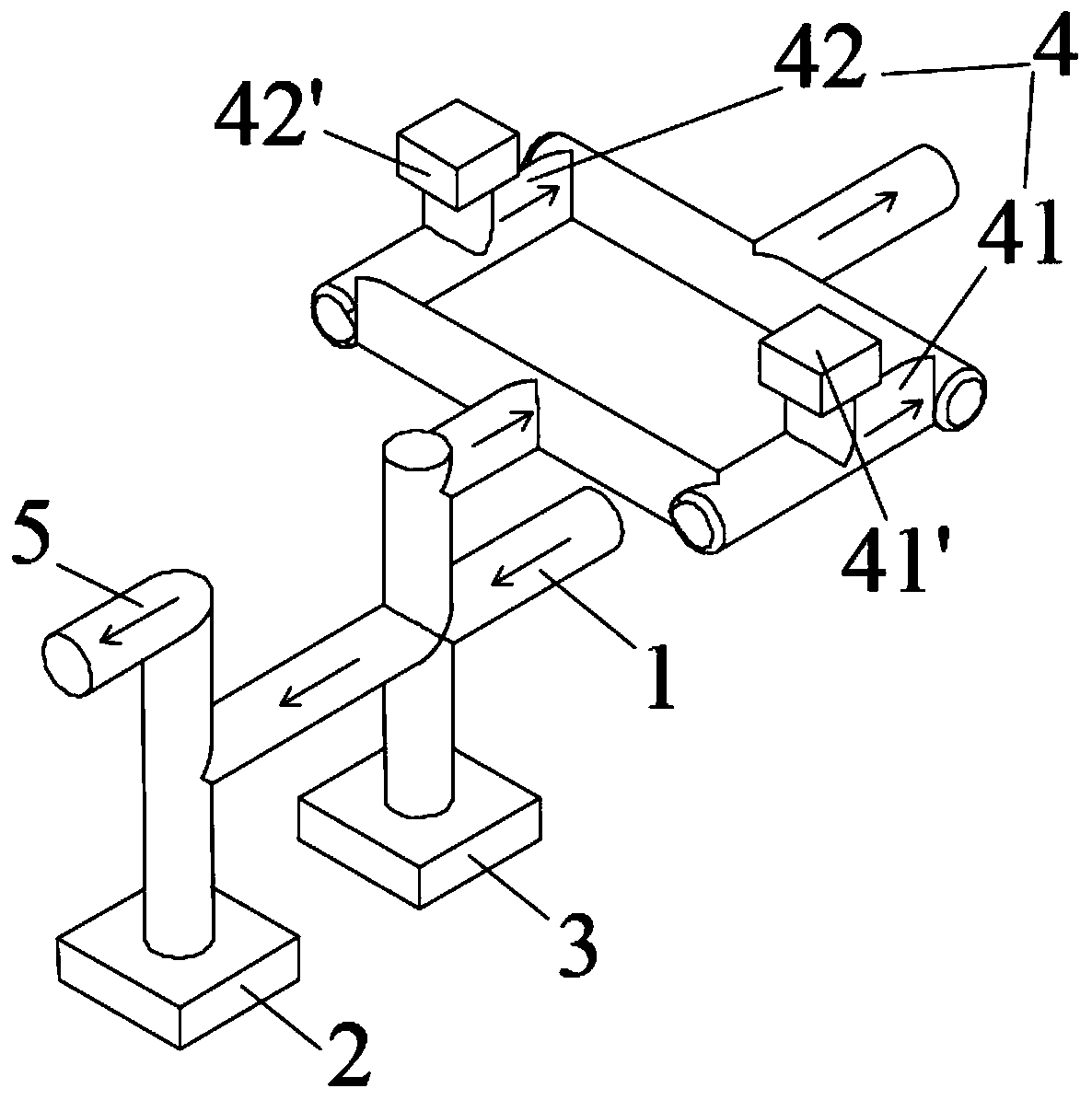

[0037] Such as figure 1As shown, a backflow device for controlling the film thickness of multi-gap pole pieces includes a feed pipe 1, a coating valve 2, a return valve 3, a return pipe 4 and a membrane head pipe 5, and the membrane head pipe 5 communicates with the feed pipe 1 , form the main road, the coating valve 2 and the return valve 3 are sequentially connected in series in the main road, the return pipe 4 communicates with the return valve 3, the return pipe 4 includes a first pipeline 41 and a second pipeline 42, the first pipeline 41 and the second pipeline 42 in parallel. In operation, when coating the membrane area, the screw pump enters the cavity of the membrane head tube 5 to form coating pressure. At this time, the return valve 3 is closed, the coating valve 2 is opened, and the slurry enters the coating membrane head 61 for coating. To the current collector, thereby forming the pole piece; when coating the blank area with large and small gaps, the coating val...

Embodiment 2

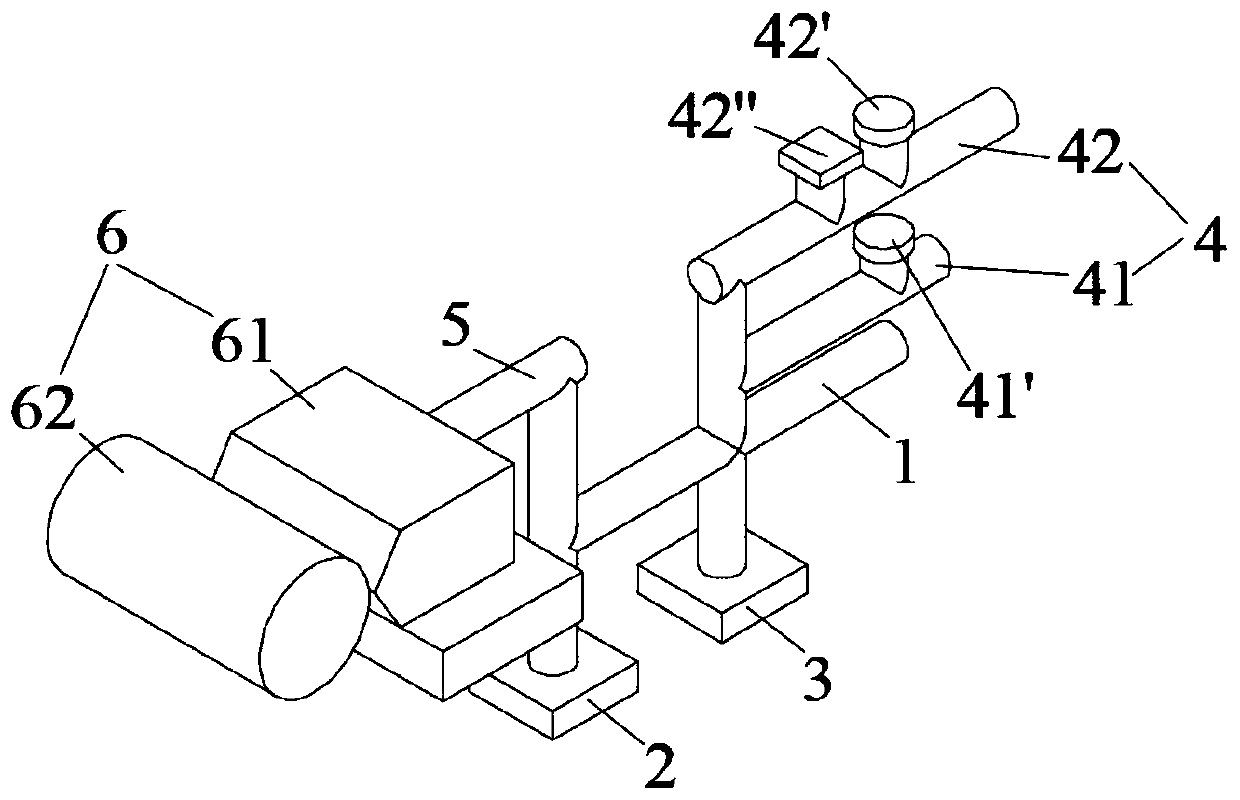

[0047] Such as figure 2 As shown, the difference from Embodiment 1 is that a second manual diaphragm valve 42 ″ is connected in series in the second pipeline 42 in this embodiment. This structural design increases the control mode of the conduction state of the second pipeline 42, which is beneficial to production.

[0048] Preferably, the second manual diaphragm valve 42'' is connected in series between the return valve 3 and the air-operated diaphragm valve 42'. This structural design makes the work of the second manual diaphragm valve 42 ″ unaffected by the air-operated diaphragm valve 42 ′, thereby increasing the stability of the work.

[0049] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0051] Such as Figure 1-2 As shown, a method for controlling the reflow device of Embodiment 1 or 2 to control the film thickness of the multi-gap pole piece includes the following steps:

[0052] Coating diaphragm area, the screw pump enters the cavity of the membrane head tube 5 to form the coating pressure, at this time the return valve 3 is closed, the coating valve 2 is opened, the slurry enters the coating membrane head 61 and is applied to the current collector, forming Pole piece;

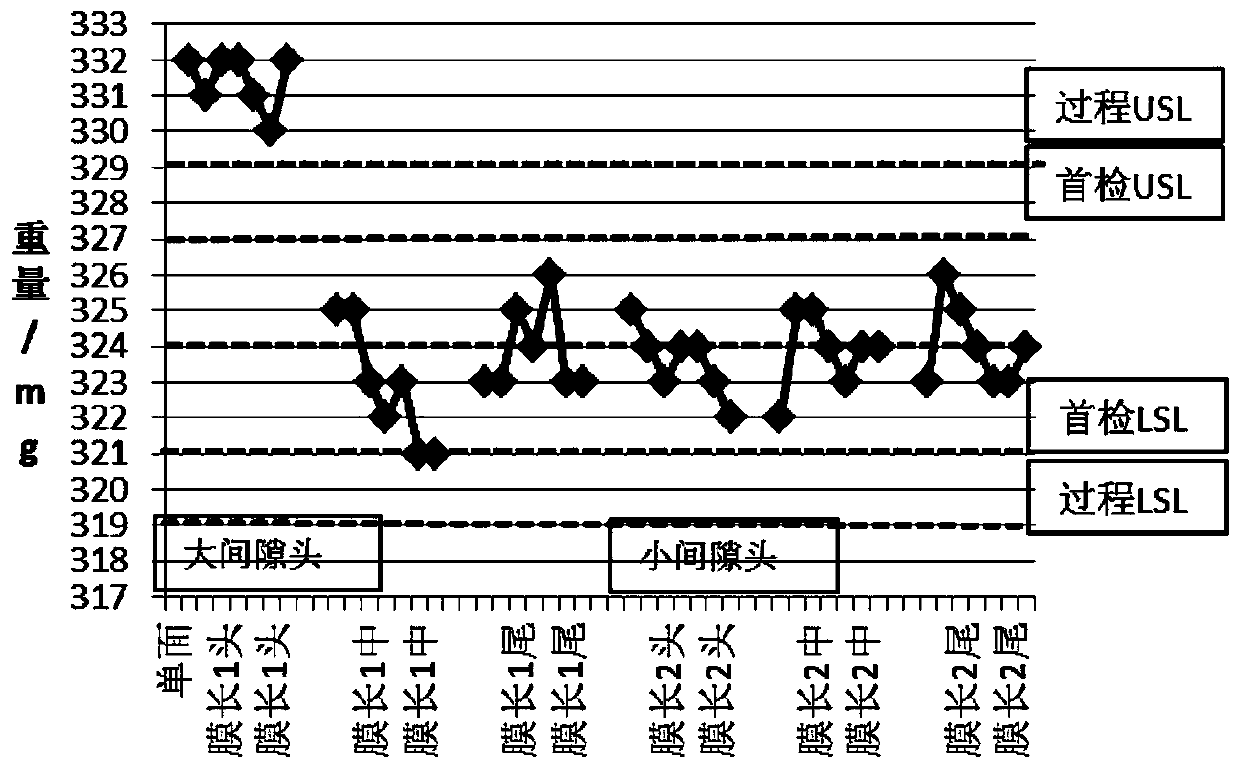

[0053] When coating the blank area with large and small gaps, the coating valve 2 is closed, and the slurry backflow adopts the first pipeline 41 and the second pipeline 42 dual-path return slurry to return to the buffer irrigation, and the dual-path return device controls the large and small gap slurry reflow;

[0054] When coating a small gap, the first manual diaphragm valve 41' in the first pipeline 41 is opened, the air-operated diaphragm valve 42' in the second pipeline 42 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com