Patents

Literature

66results about How to "Reduce electric shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

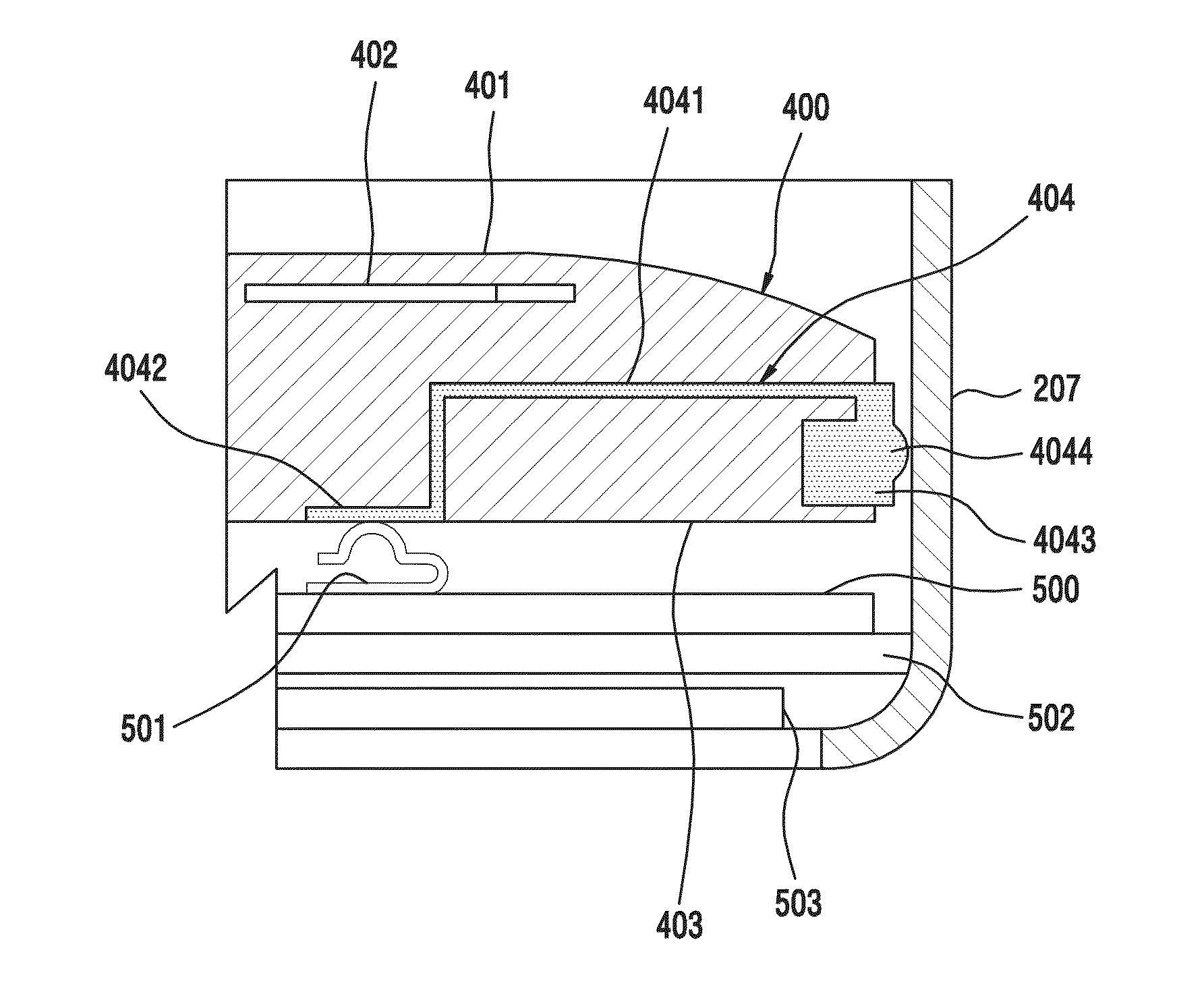

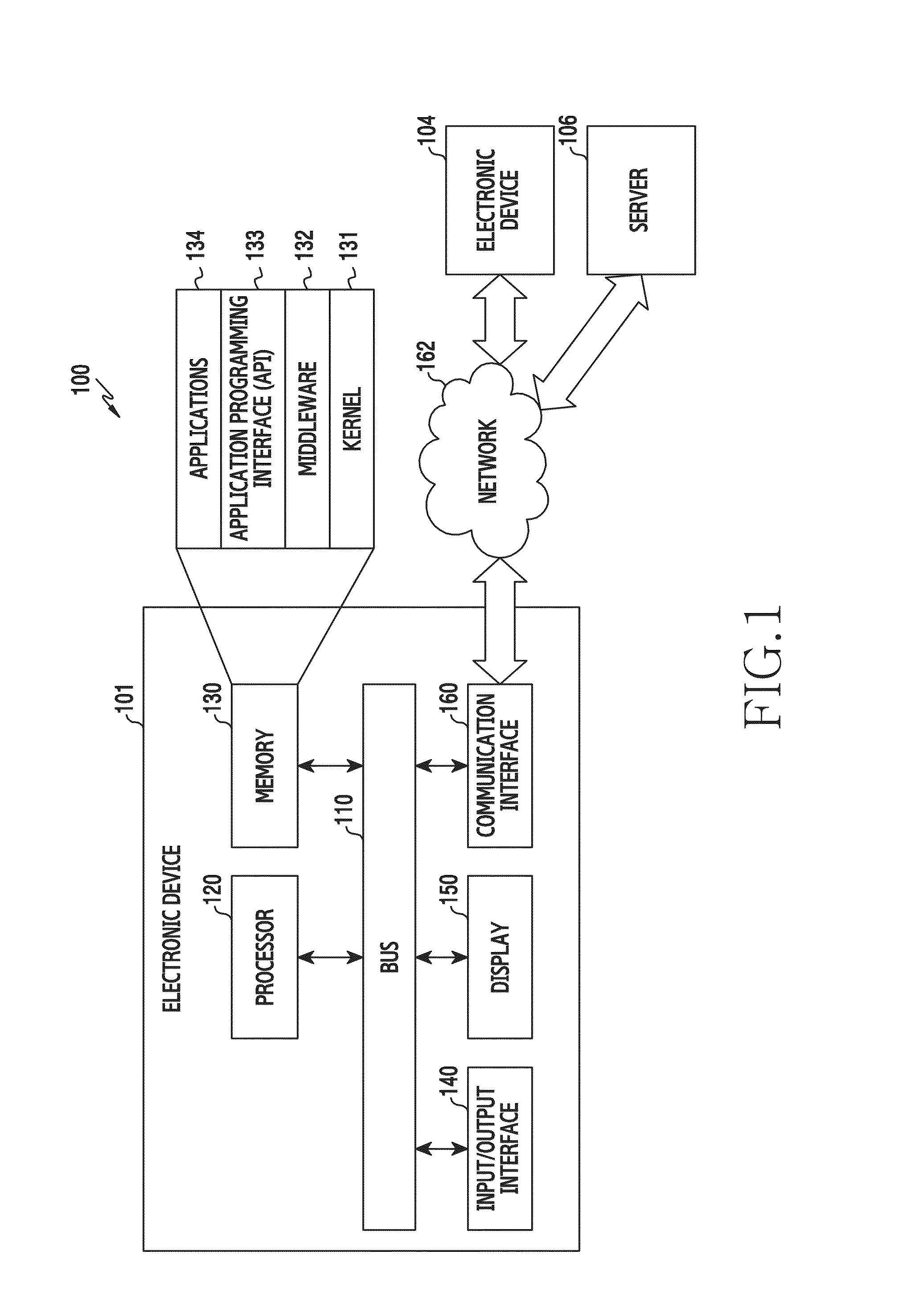

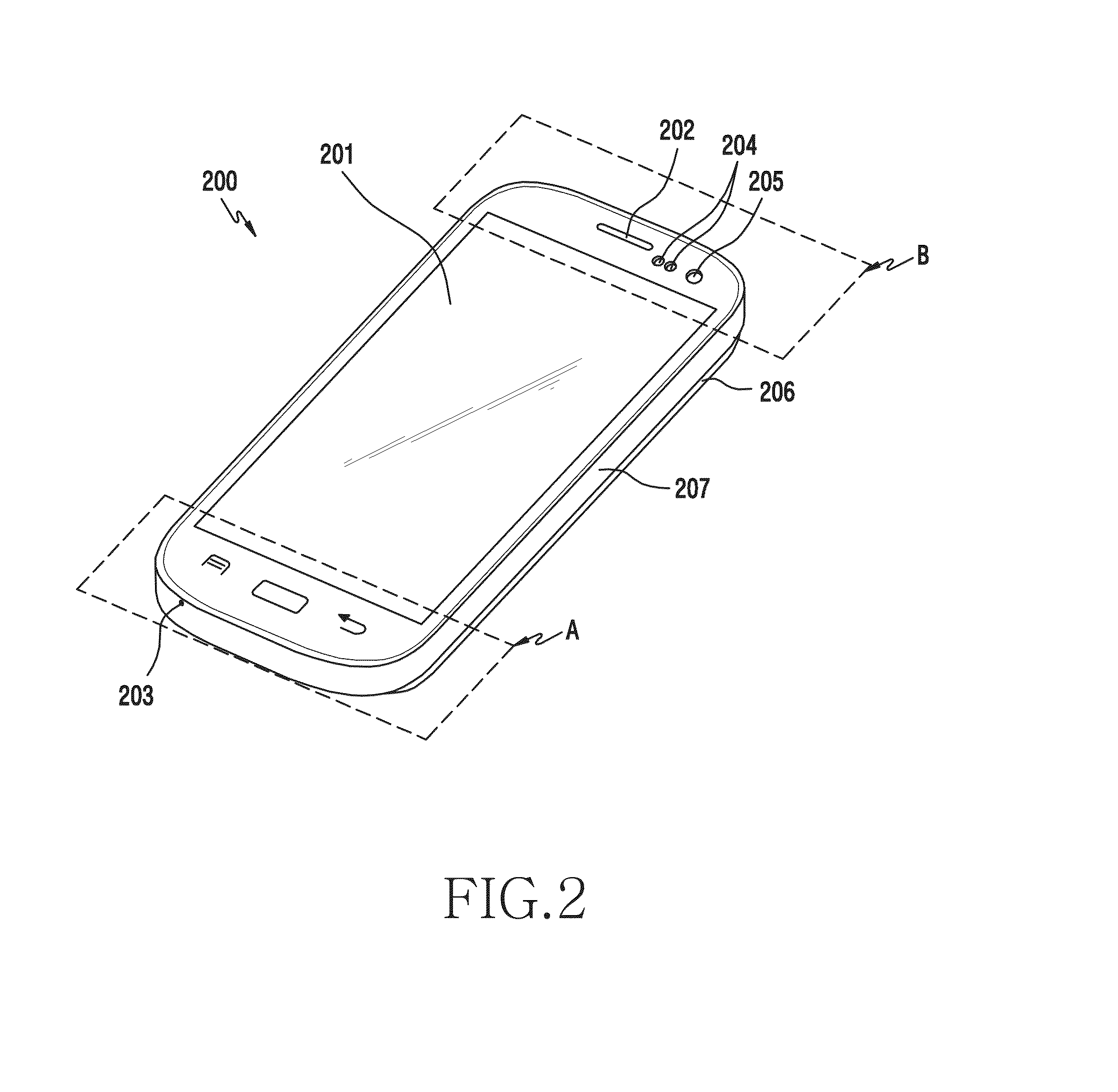

Electrical connection device and electronic device having same

ActiveUS20160018856A1Improve antenna performanceReduce electric shockDigital data processing detailsSubstation equipmentElectricityElectrical conductor

An electronic device includes a substrate, a structure arranged near the substrate and includes at least one electronic component, a conductive structure provided in the electronic device, and a conductor arranged in the structure, grounding the conductive structure to a ground of the substrate. Electronic components spaced within the electronic device are electrically connected to each other using the existing structure to be installed, so that a mounting space for preparing an electrical connector is prevented from being wasted, thereby making the electronic device slim. The embodiments according to the present disclosure can reduce the number of assembling processes and manufacturing costs.

Owner:SAMSUNG ELECTRONICS CO LTD

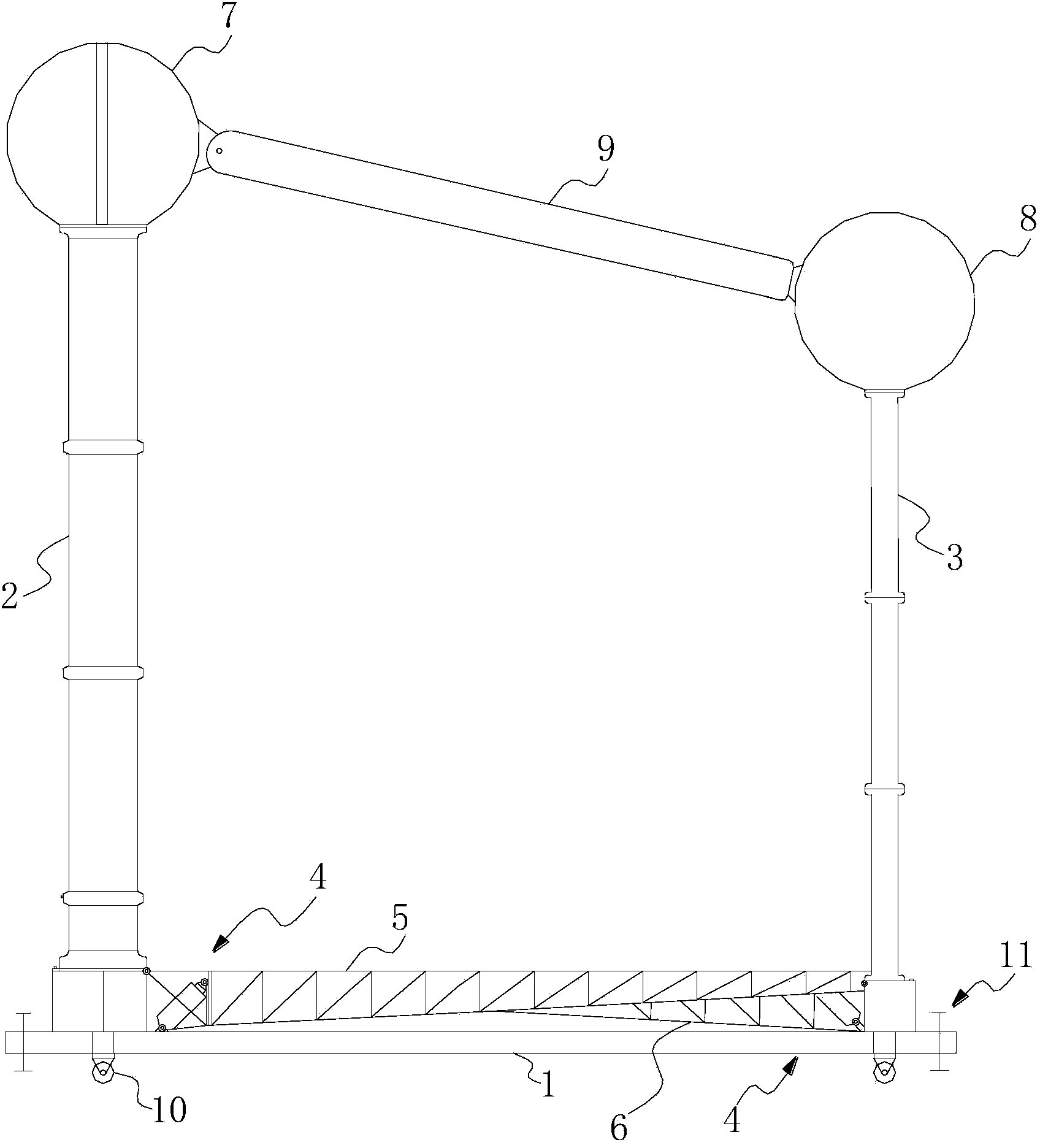

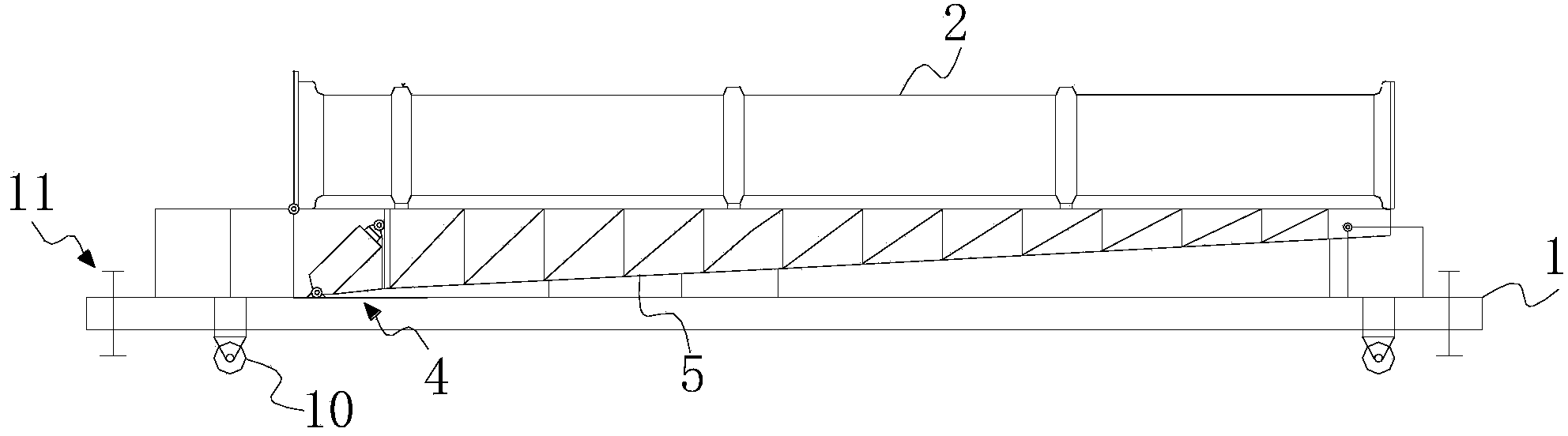

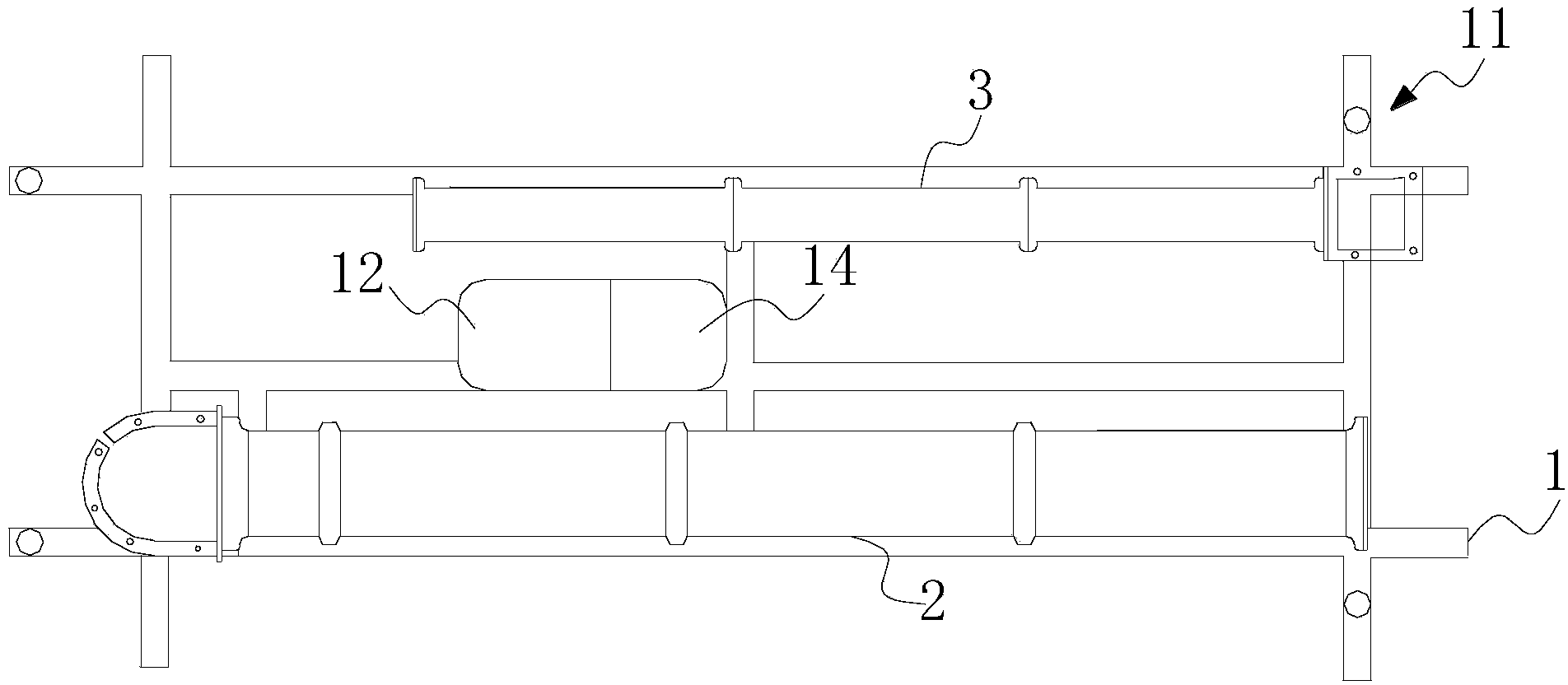

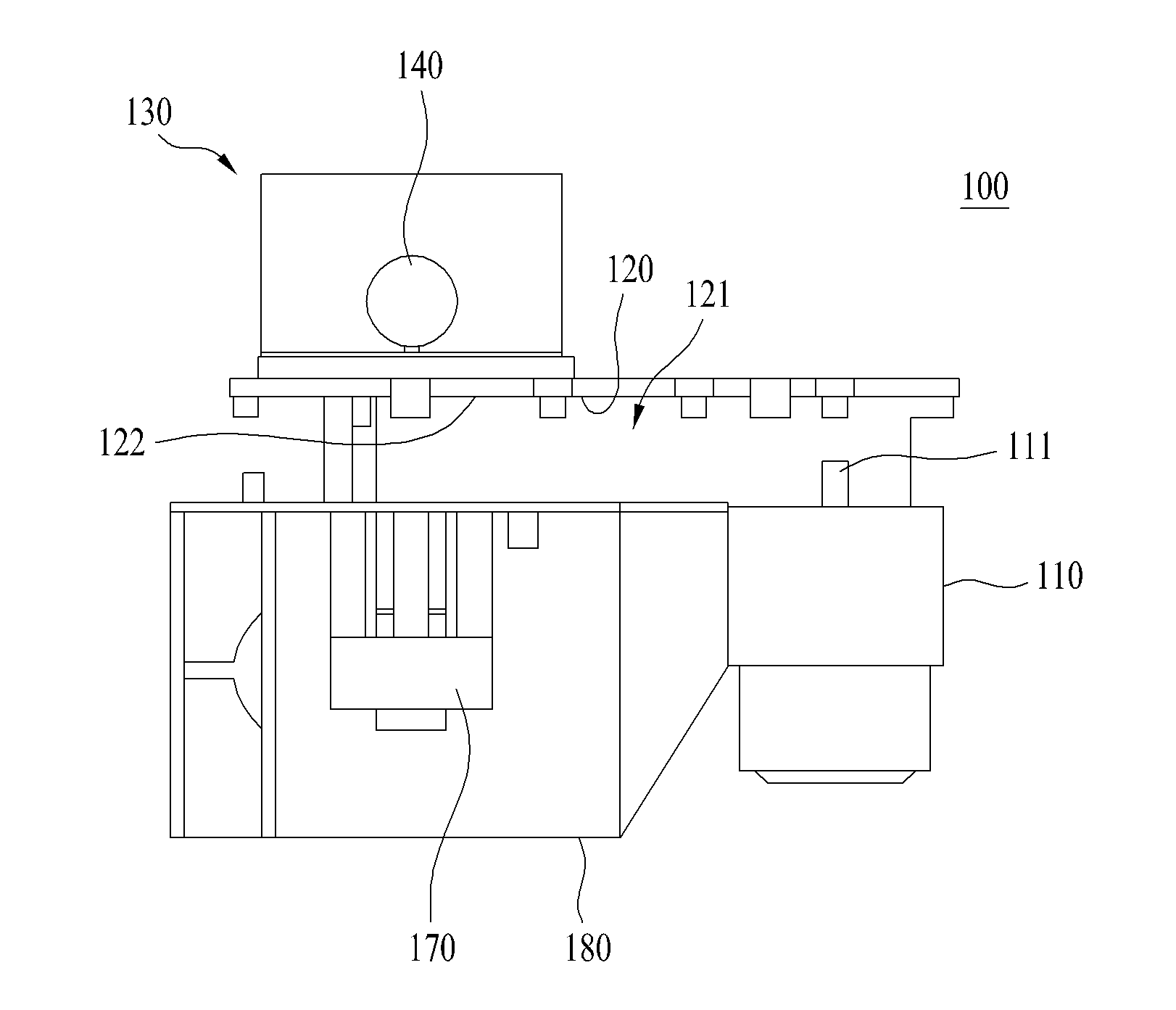

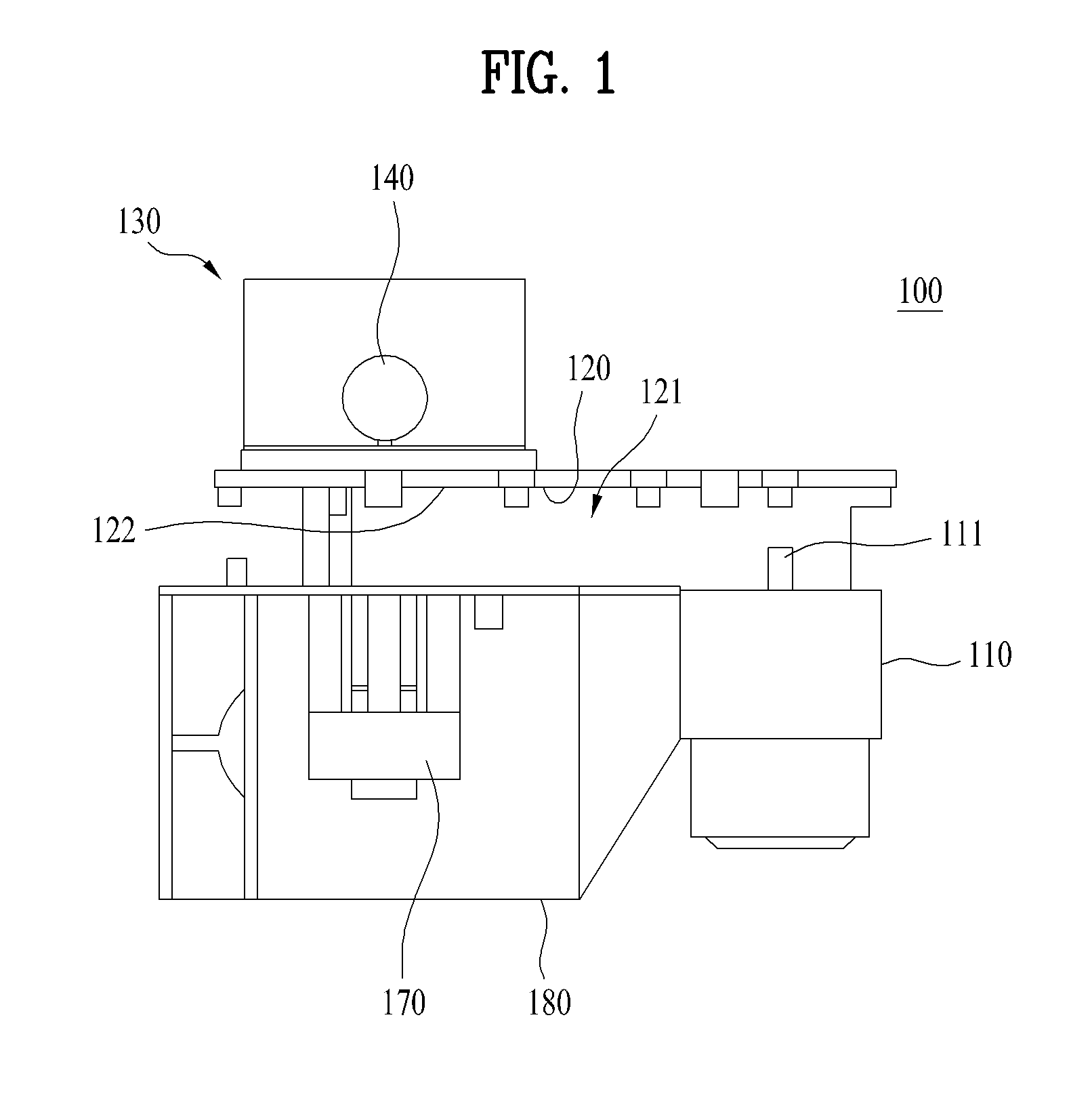

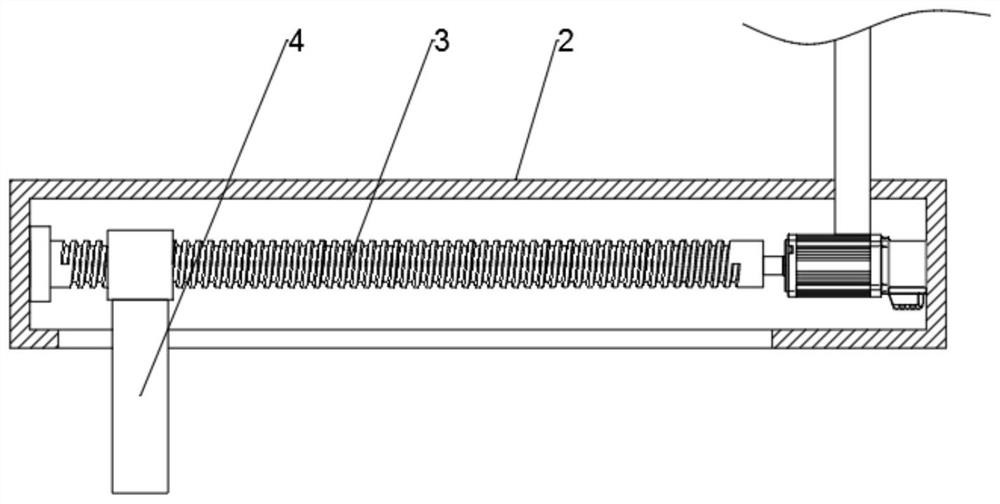

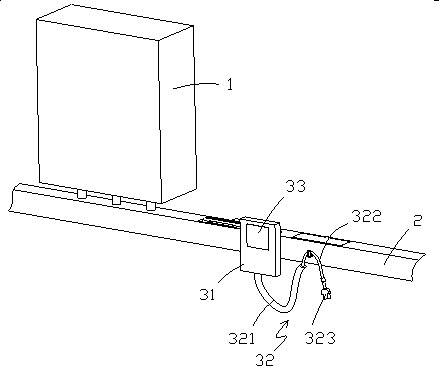

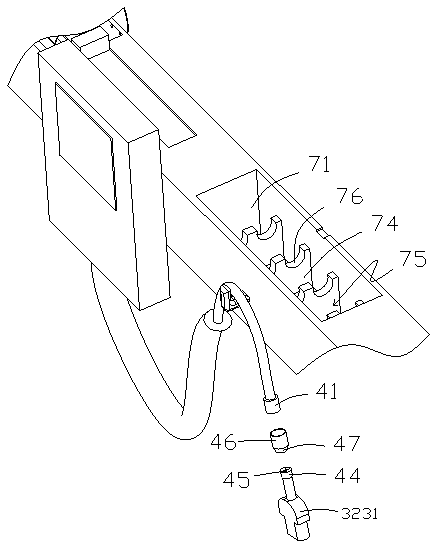

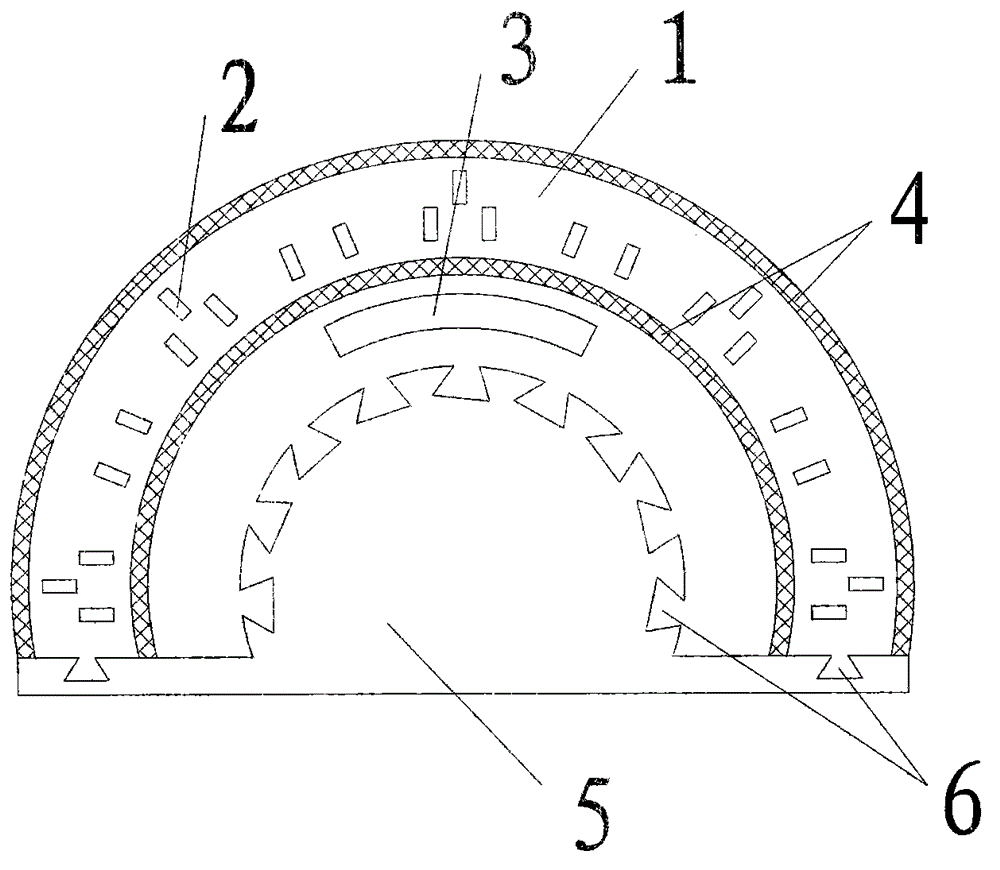

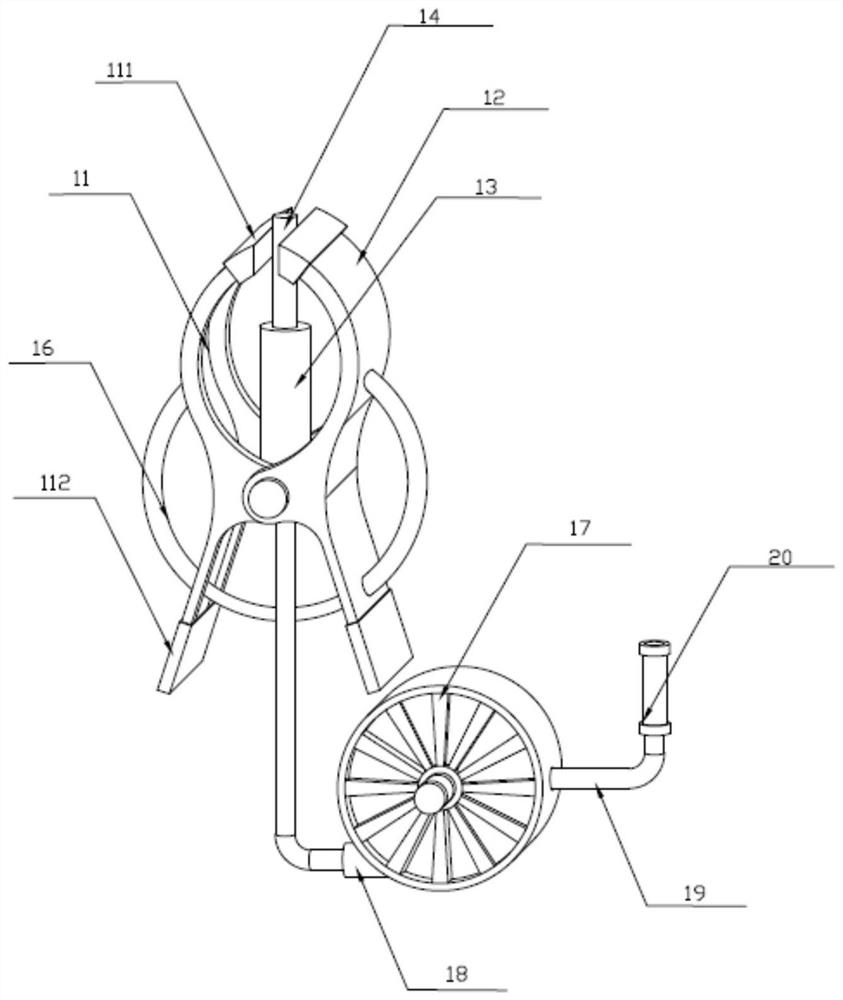

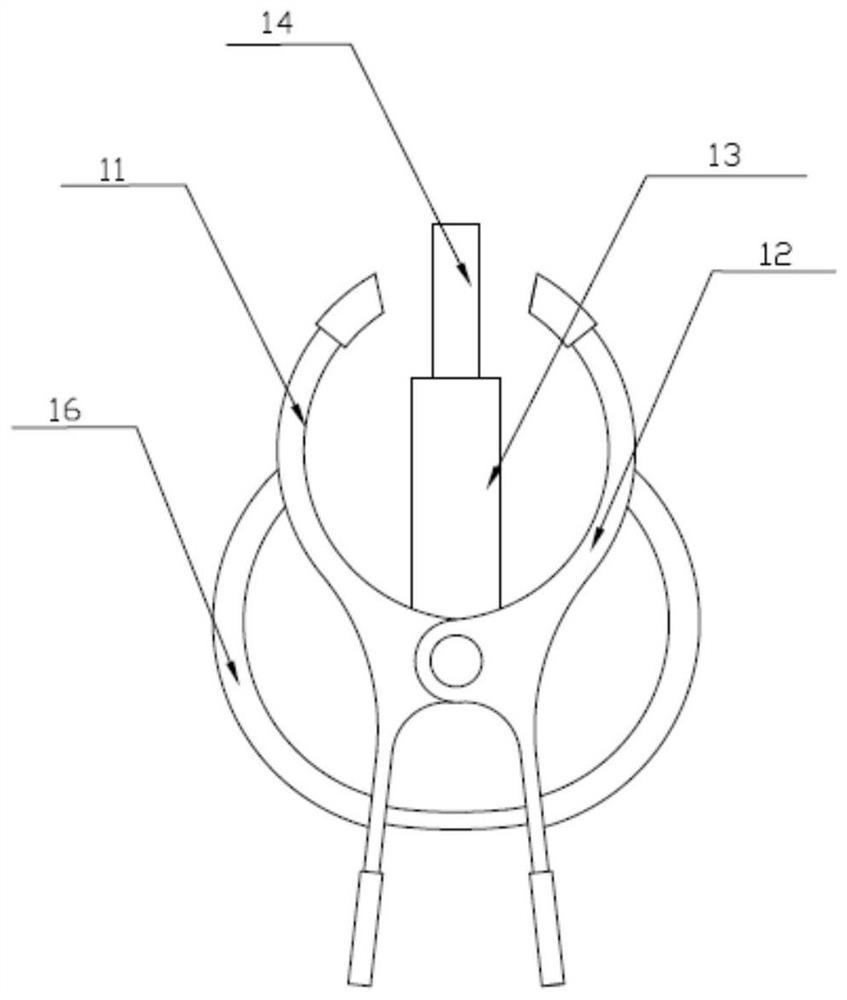

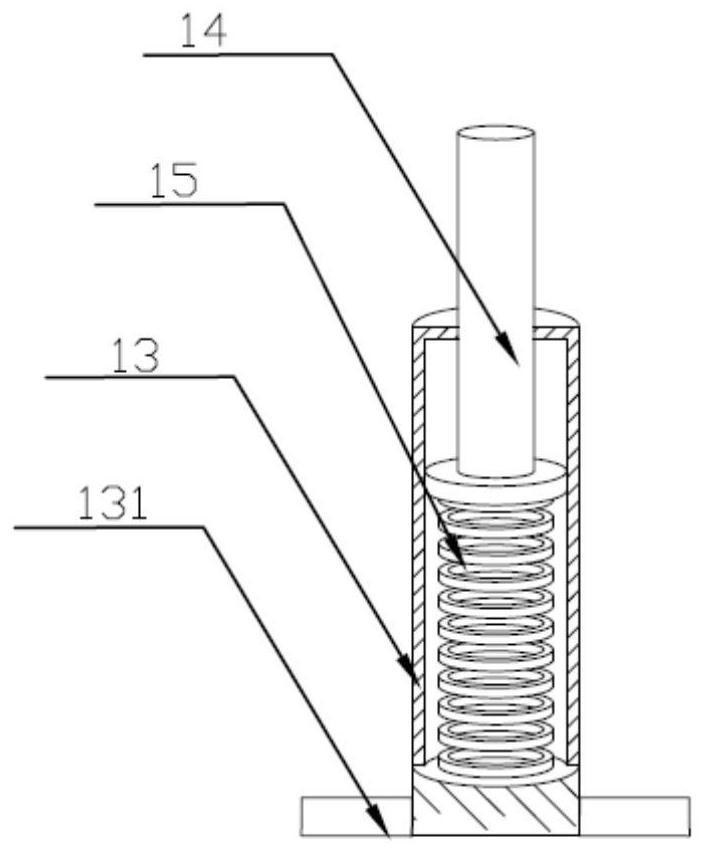

Withstand voltage testing system and assembly method thereof

ActiveCN103777122AAvoid drudgeryReduce electric shockTesting dielectric strengthFree rotationCapacitive voltage divider

The invention relates to the technical field of high-voltage electrical withstand voltage testing equipment, in particular to a withstand voltage testing system and an assembly method thereof. The withstand voltage testing system comprises a base, a high-voltage electric reactor capable of being fixed onto the base, a capacitive voltage divider capable of being fixed onto the base, a hydraulic lifting device, a first voltage-sharing shield, a second voltage-sharing shield and a contact tube. The hydraulic lifting device is arranged on the base in a free rotation mode and comprises a first hydraulic lifting arm for supporting the high-voltage reactor to be positioned at any position from the horizontal direction to the vertical direction and a second hydraulic lifting arm for supporting the capacitive voltage divider to be positioned at any position from the horizontal direction to the vertical direction; the first voltage-sharing shield is detachably connected to the end of the high-voltage reactor; the second voltage-sharing shield is detachably connected to the end of the capacitive voltage divider; the contact tube is movably connected between the first voltage-sharing shield and the second voltage-sharing shield. The withstand voltage testing system is convenient to transport, does not need to be disassembled or assembled frequently, is convenient and fast to operate and high in safety coefficient, and meets the requirements of withstand voltage tests.

Owner:符棠

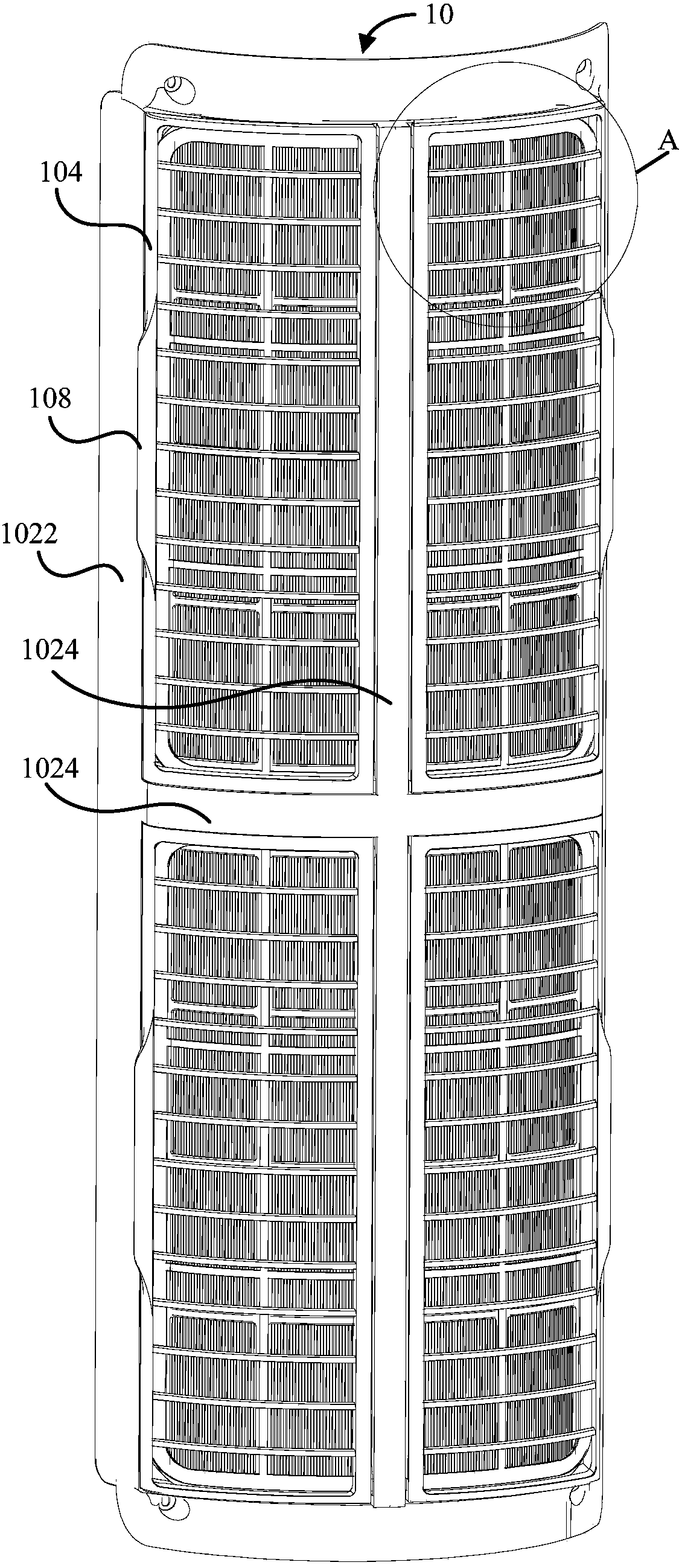

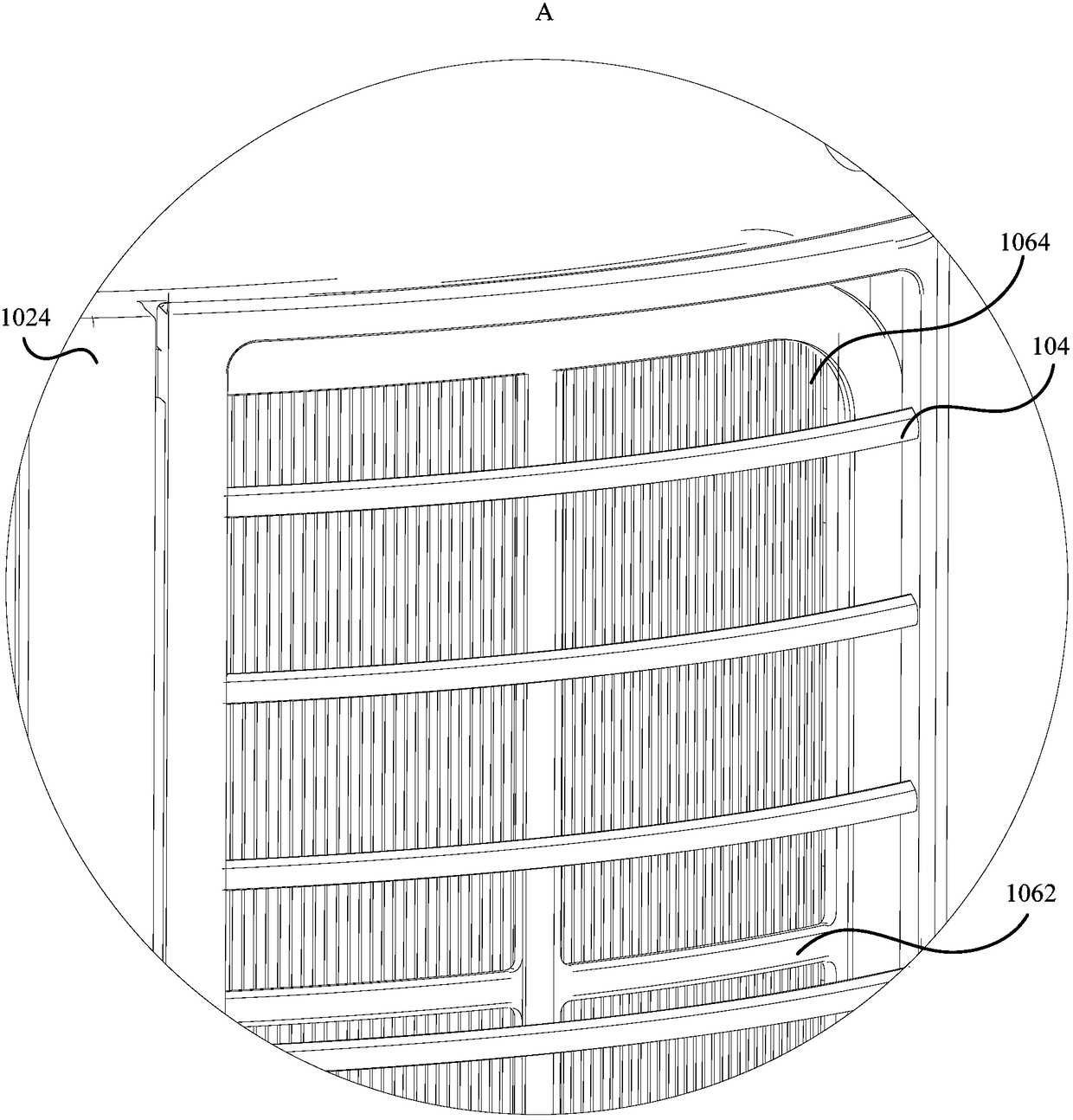

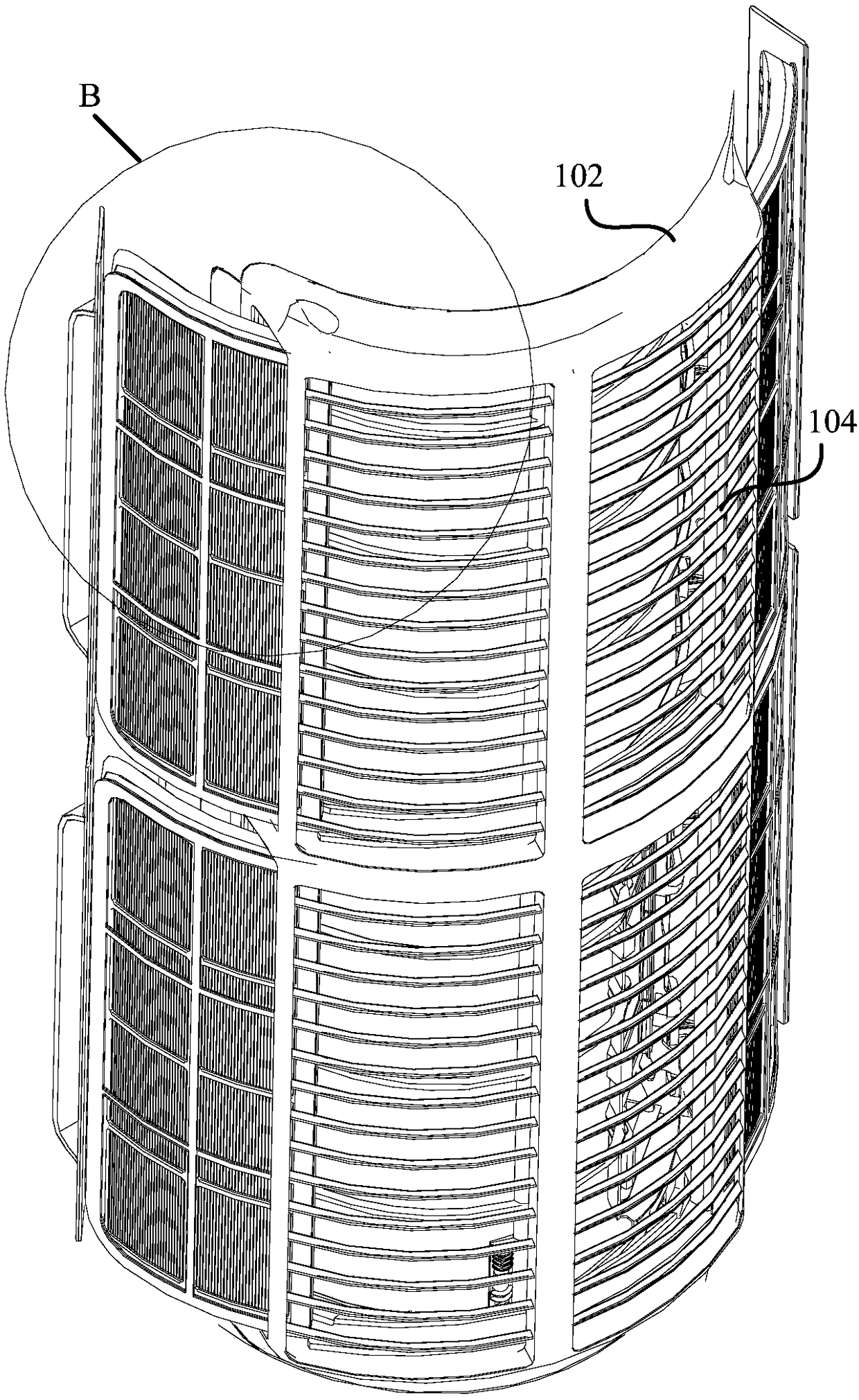

Purifying module and air conditioner

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Terminal short circuit protection method and device

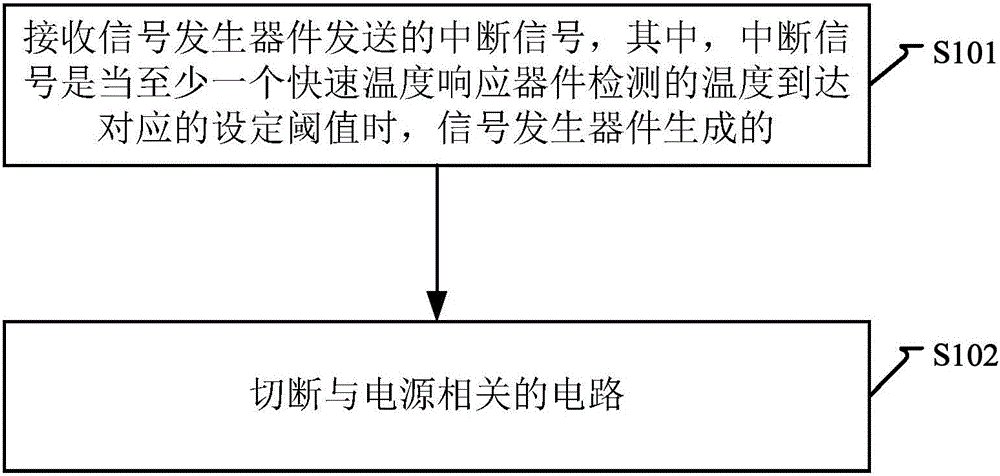

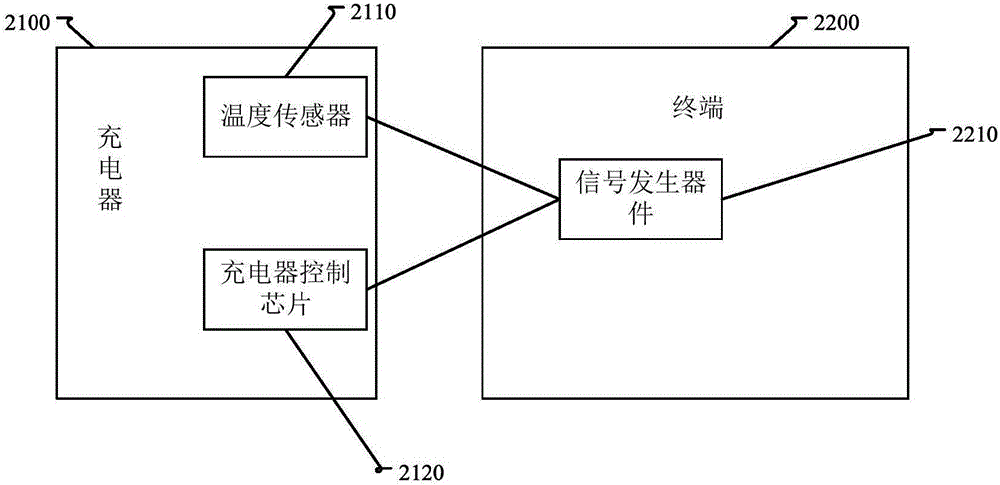

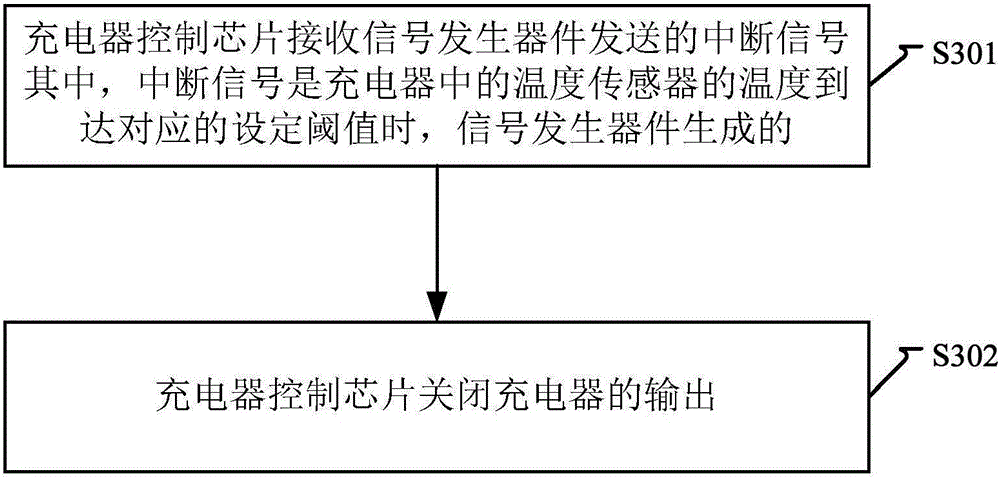

ActiveCN106026264AReduce the probability of short circuit misjudgmentImprove accuracyElectric powerBattery disconnect circuitsTemperature responseShort circuit protection

The invention relates to a terminal short circuit protection method and a device. At least one first electronic component which is in a system of a terminal and is relevant to charging and discharging is equipped with a corresponding rapid temperature response device, and at least one electronic control component of the system of the terminal corresponding to the first electronic component is connected with a signal generation device corresponding to the rapid temperature response device. The method comprises steps that an interruption signal sent by the signal generation device is received by the electronic control component, the interruption signal is generated by the signal generation device when detection temperature of at least one rapid temperature response device reaches a corresponding set threshold, and circuits related to a power source are cut off. Through the method and the device, the circuits related to the power source can be cut off through the electronic control component after the temperature of the electronic component rises to the set threshold because of short circuit, the terminal can be prevented from being damaged by continuous energy, and safety of the terminal is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

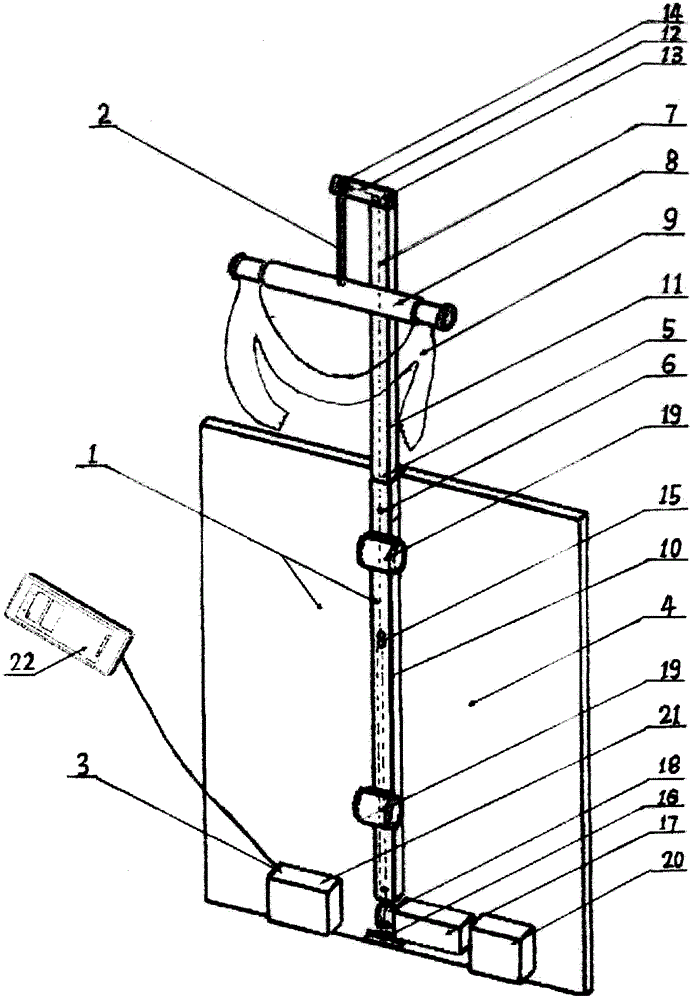

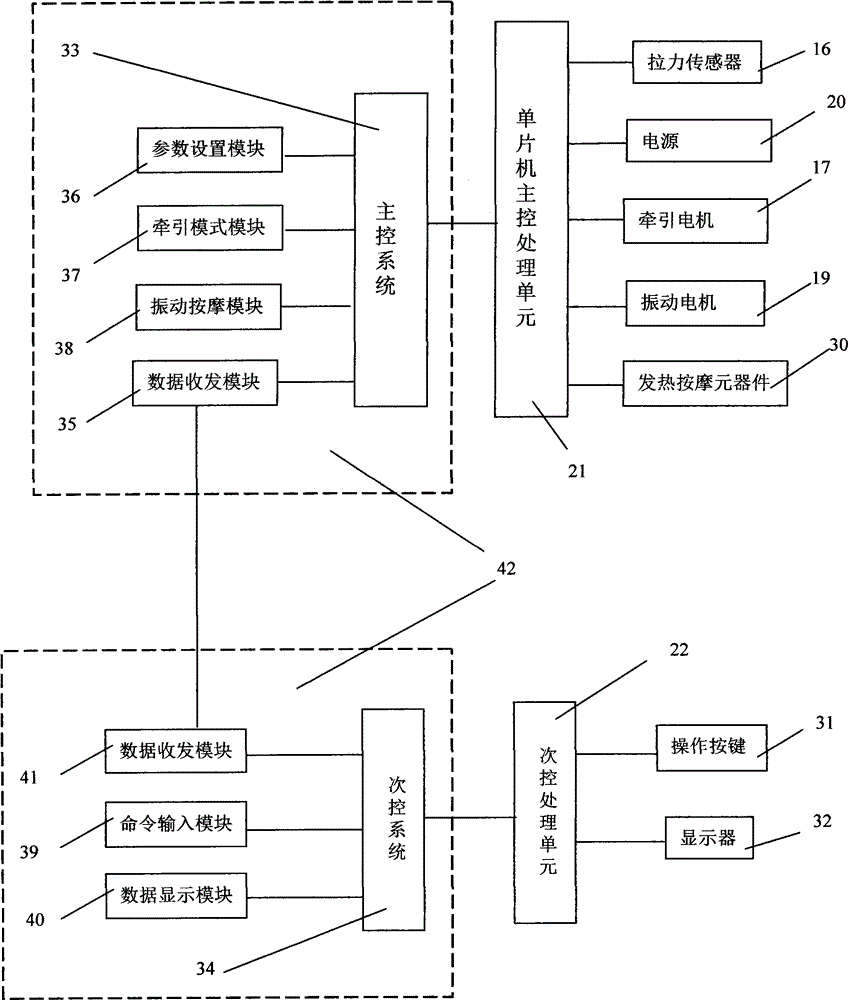

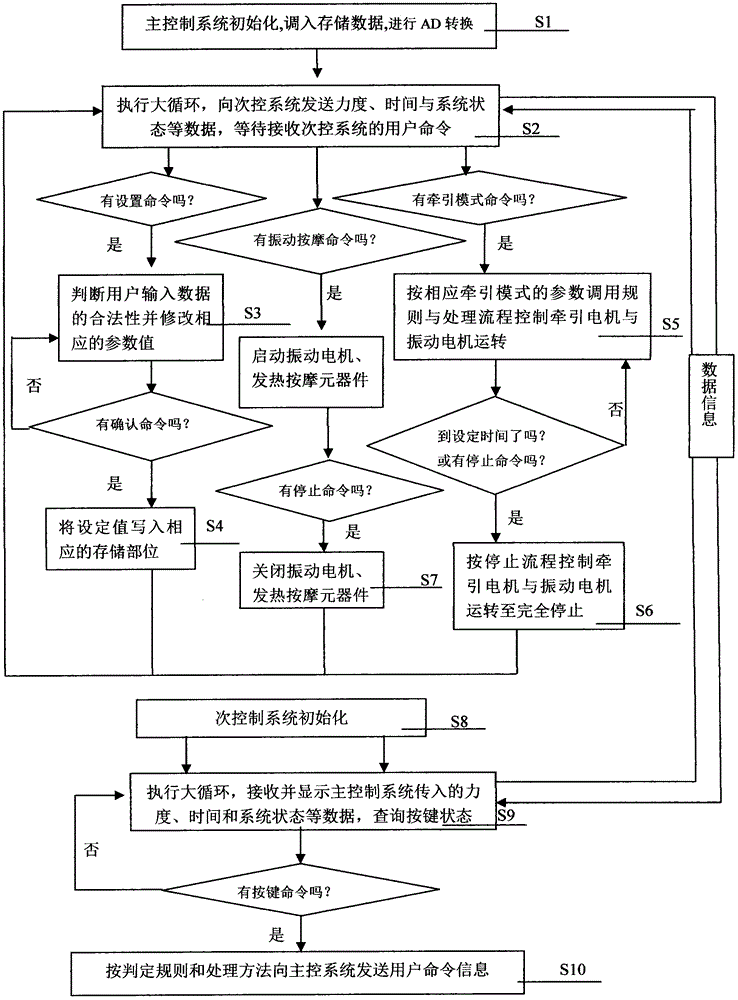

Pulse vibration type spine traction device which can be embedded into furniture

The invention discloses a pulse vibration type spine traction device which can be embedded into a piece of furniture. The pulse vibration type spine traction device comprises a traction supporting mechanism, a traction transmission mechanism and a power and operation system, wherein the traction supporting mechanism comprises a base formed by a back plate or a base frame of the furniture and a supporting module composed of a sleeve, the traction transmission mechanism comprises a flexible transmission member formed by connecting a rope-shaped object and a pulley, a traction hanger and a traction belt, and the power and operation system comprises a power supply, a motor, a sensor, a control unit, an operating key, a displayer and a software system. The pulse vibration type spine traction device has the advantages that complete integration of special traction facilities, chairs, sofa and household furniture is achieved, the original appearance and functions of the furniture are kept, an automatic dynamic pulse vibration type traction function is added, the rationality, safety, comfort and convenience in the traction process are improved, an application range is widened, and spinal disease prevention and control are conveniently introduced to homes and office places.

Owner:三门峡市同成医疗设备有限公司

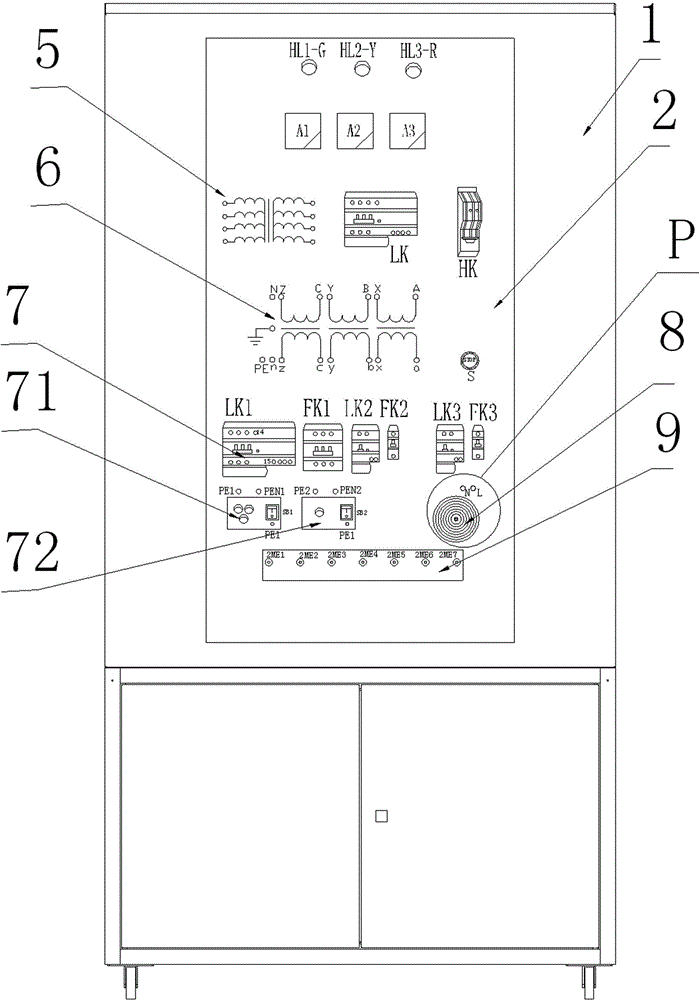

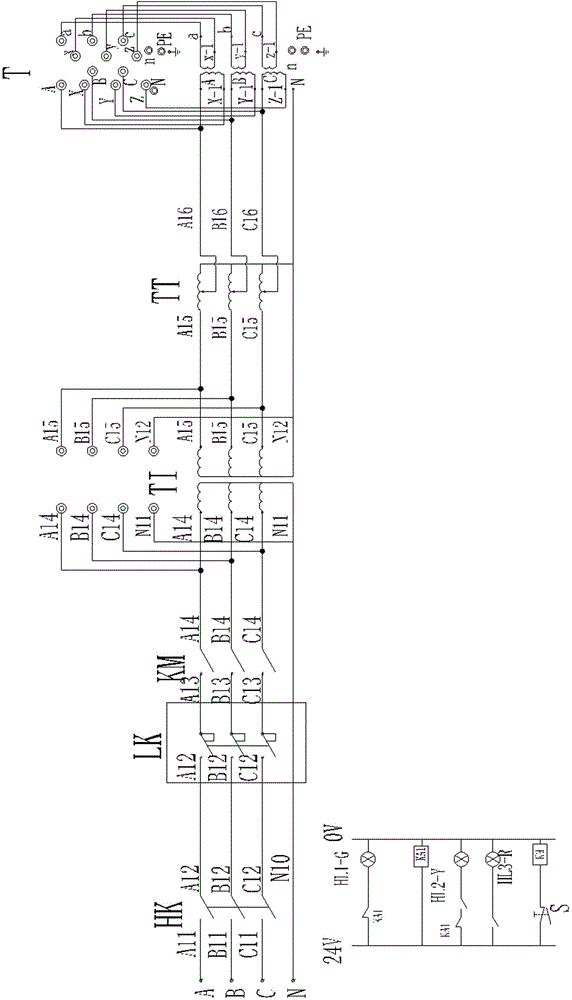

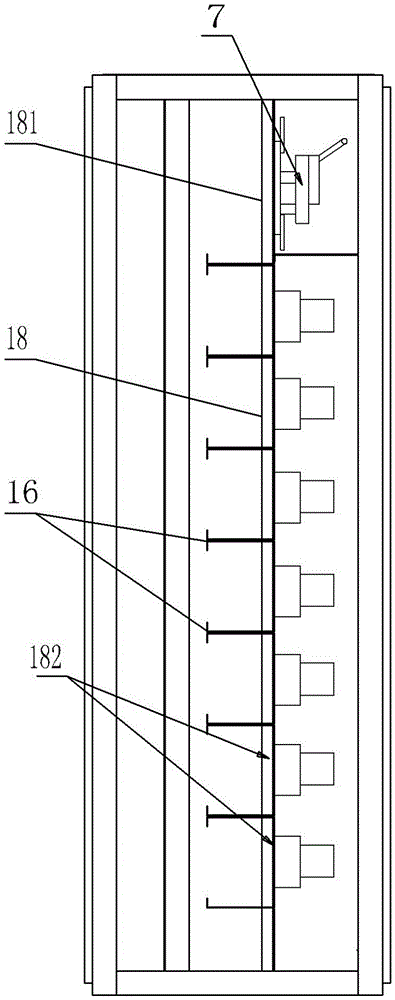

Electrical teaching practical training multifunctional cabinet

ActiveCN103559823AIncrease profitEasy to keepCosmonautic condition simulationsEducational modelsPower utilityElectric power

The invention relates to an electrical teaching practical training multifunctional cabinet. The electrical teaching practical training multifunctional cabinet comprises a vertical cabinet body, wherein a teaching practical training device for electrical power safety utilization protection is arranged on the front face of the vertical cabinet body, a teaching practical training device for electrical energy saving displaying is arranged on the left side face of the vertical cabinet body, and a teaching practical training device for photovoltaic power generation is arranged on the right side face of the vertical cabinet body. According to the electrical teaching practical training multifunctional cabinet, the plurality of scattered practical training devices are integrated onto the same cabinet body, and therefore the scattered practical training devices can be conveniently moved, carried and stored without being lost, training efficiency is greatly improved, practical training cost is reduced, and electrical scientific propaganda of an electric power company is facilitated.

Owner:STATE GRID CORP OF CHINA +1

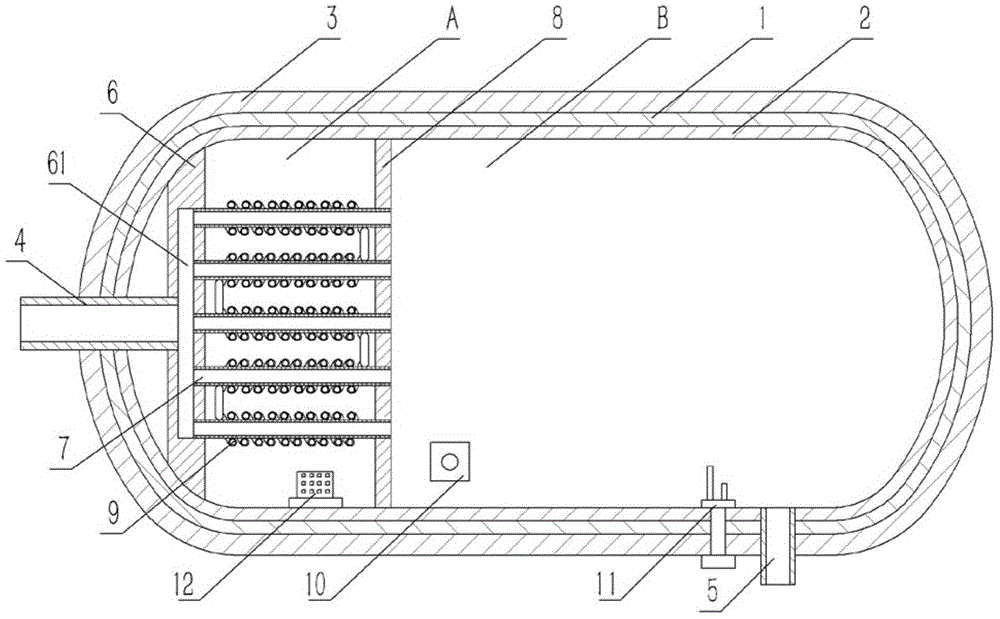

Insulation safety type electrical water heater

The invention relates to an insulation safety type electrical water heater, which comprises a water storage inner container of the water heater, a water inlet pipe and a water outlet pipe, wherein the water inlet pipe and the water outlet pipe are respectively fixed on the water storage inner container and is communicated with the inner cavity of the water storage inner container; a ceramic insulating layer is fixed on the inner side wall of the water storage inner container; an insulating layer is fixed on the outer side wall of the water storage inner container; a division board is fixed in the water storage inner container and divides the inner cavity of the water storage inner container into a water storage cavity and a heating cavity; a heating pipe is fixedly connected into the heating cavity and is spirally wound on a plurality of quartz glass tubes; one ends of the quartz glass tubes are fixed on the division board and are communicated with the water storage cavity; the other ends of the quartz glass tubes are fixed on a splitter plate; the splitter plate is fixed on the water storage inner container; a water channel is formed in the splitter plate and is respectively communicated with the quartz glass tubes and the water inlet pipe; the outlet end of the water inlet pipe is fixed on the splitter plate; a humidity sensor is fixed on the bottom part of the heating cavity. The safety of the electrical water heater is improved.

Owner:杨秀枝

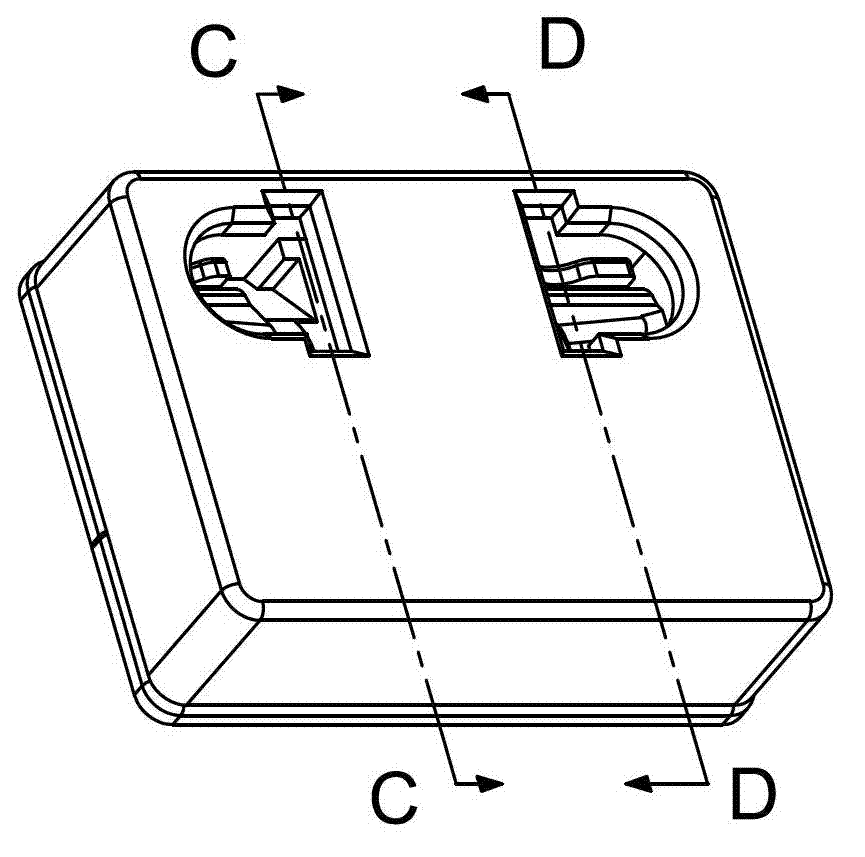

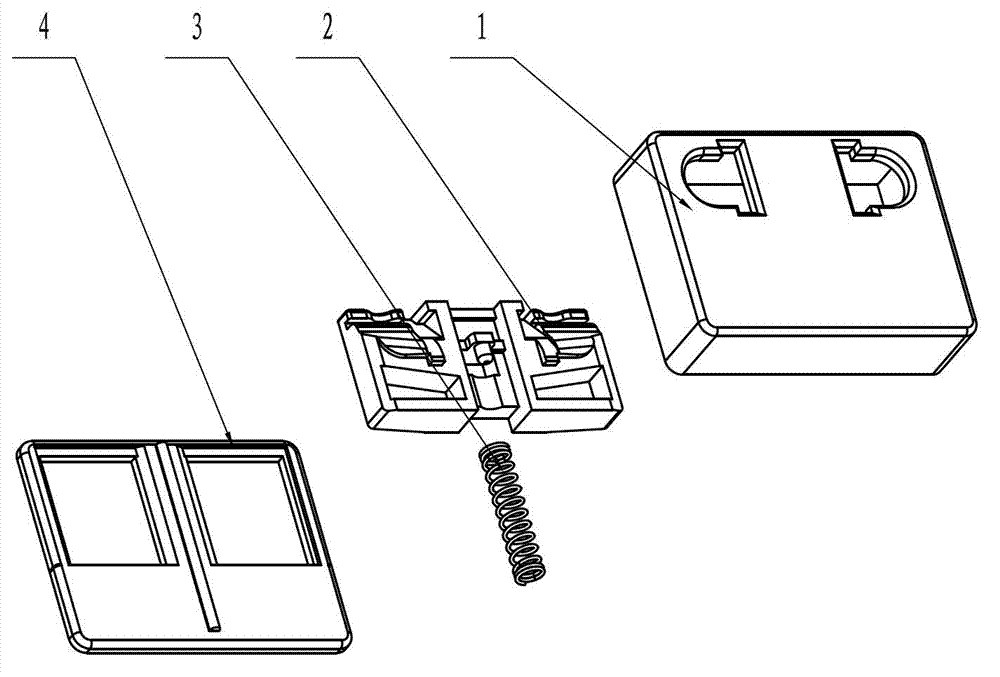

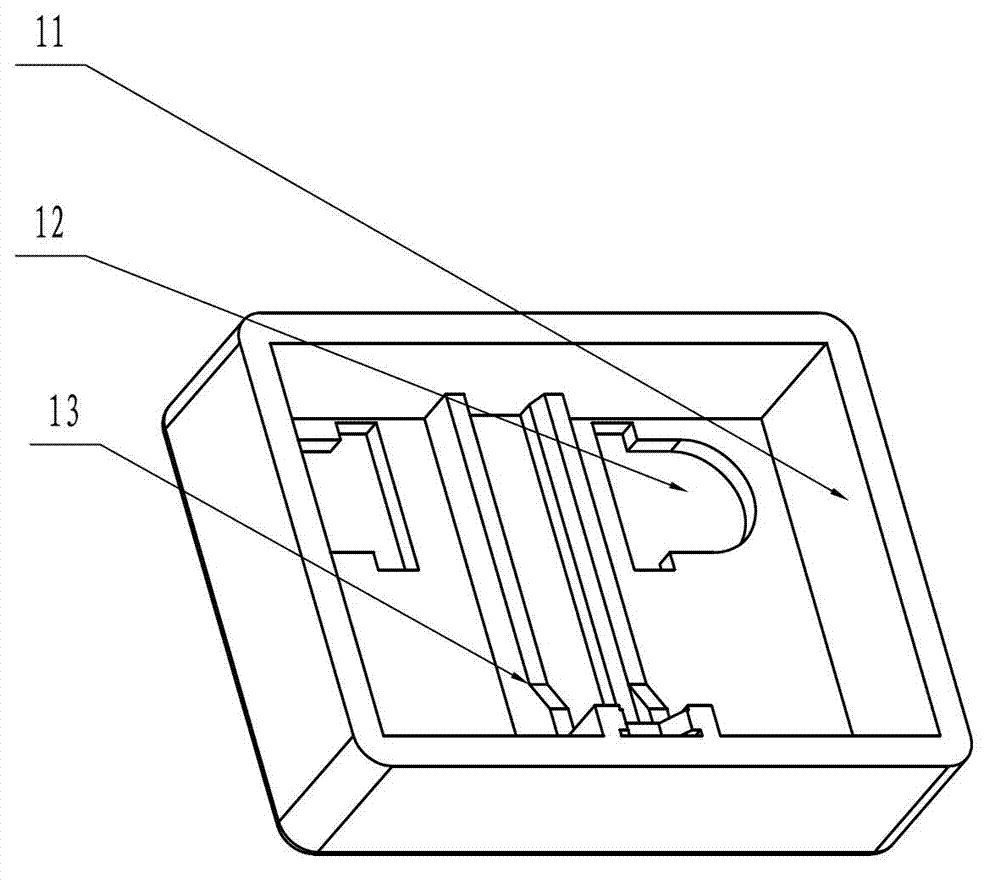

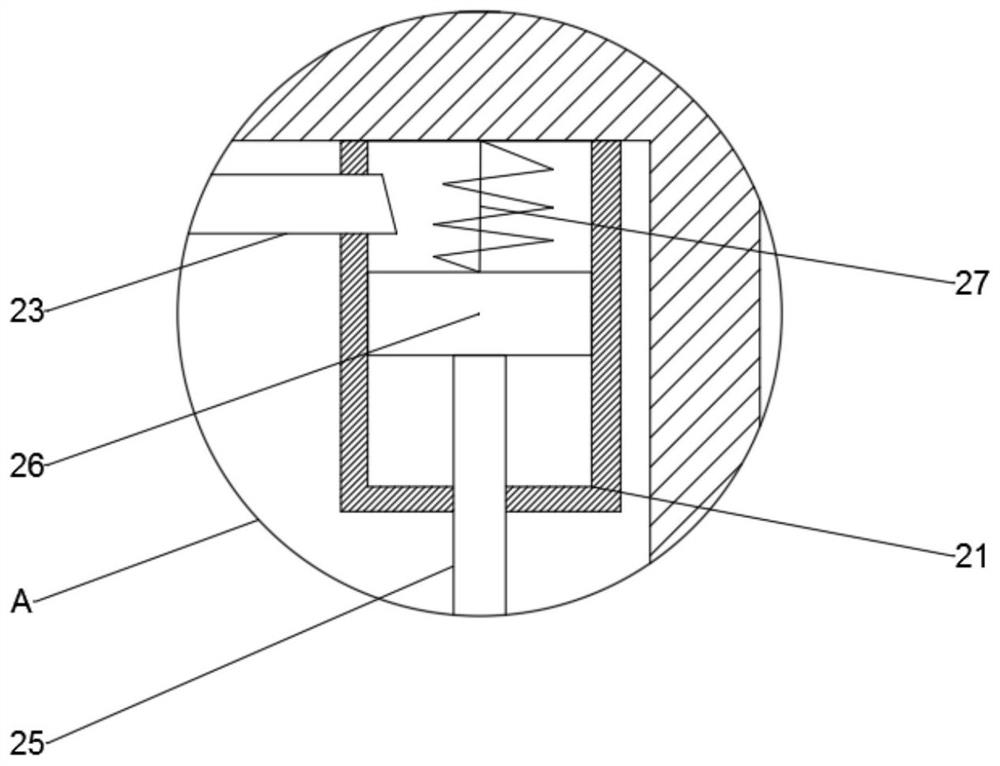

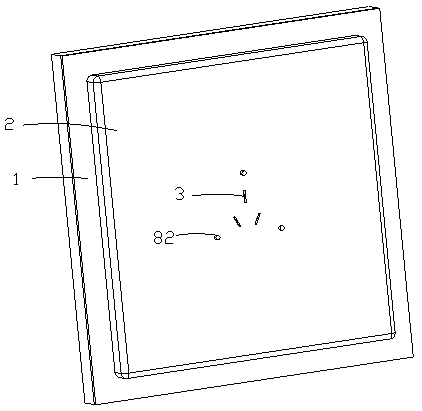

Safety mechanism

ActiveCN102931514AEffective anti-insertionAnti-insertionCoupling device detailsElectric shockClosed state

The invention discloses a safety mechanism. The safety mechanism comprises a cover plate, a bottom plate, a protection door and a return spring. A second inclined plane, a first inclined plane, rib plates, a middle groove and a limiting boss are arranged on the front face of the protection door. The cover plate is provided with side plates, two bolt holes and two paralleled rib plates. The bottom plate is provided with a protruding rib and two through holes. The middle groove of the front face of the protection door is matched with the two paralleled rib plates, and enables the protection door to move along the two paralleled rib plates front to back to form opening and closing when the return spring is compressed and extended. When the protection door is stressed on one side, the protection door deflects towards the other side, a sinking edge sinks into the through holes of the bottom plate and stops the protection door from sliding towards one side, and the limiting boss of an cocking-up edge of the protection door is inserted into an inserting hole of the cover plate and prevents the protection door from sliding backwards and being opened. The side plates surrounding the cover plate can guarantee the protection door to slide horizontally so that the protection door is always arranged in a closed state. Besides, thin and long conducting materials can be prevented from contacting live parts when being inserted from the inserting hole in any angle, and therefore possibility of electric shock is reduced.

Owner:ZHEJIANG CHINT BUILDING ELECTRICS

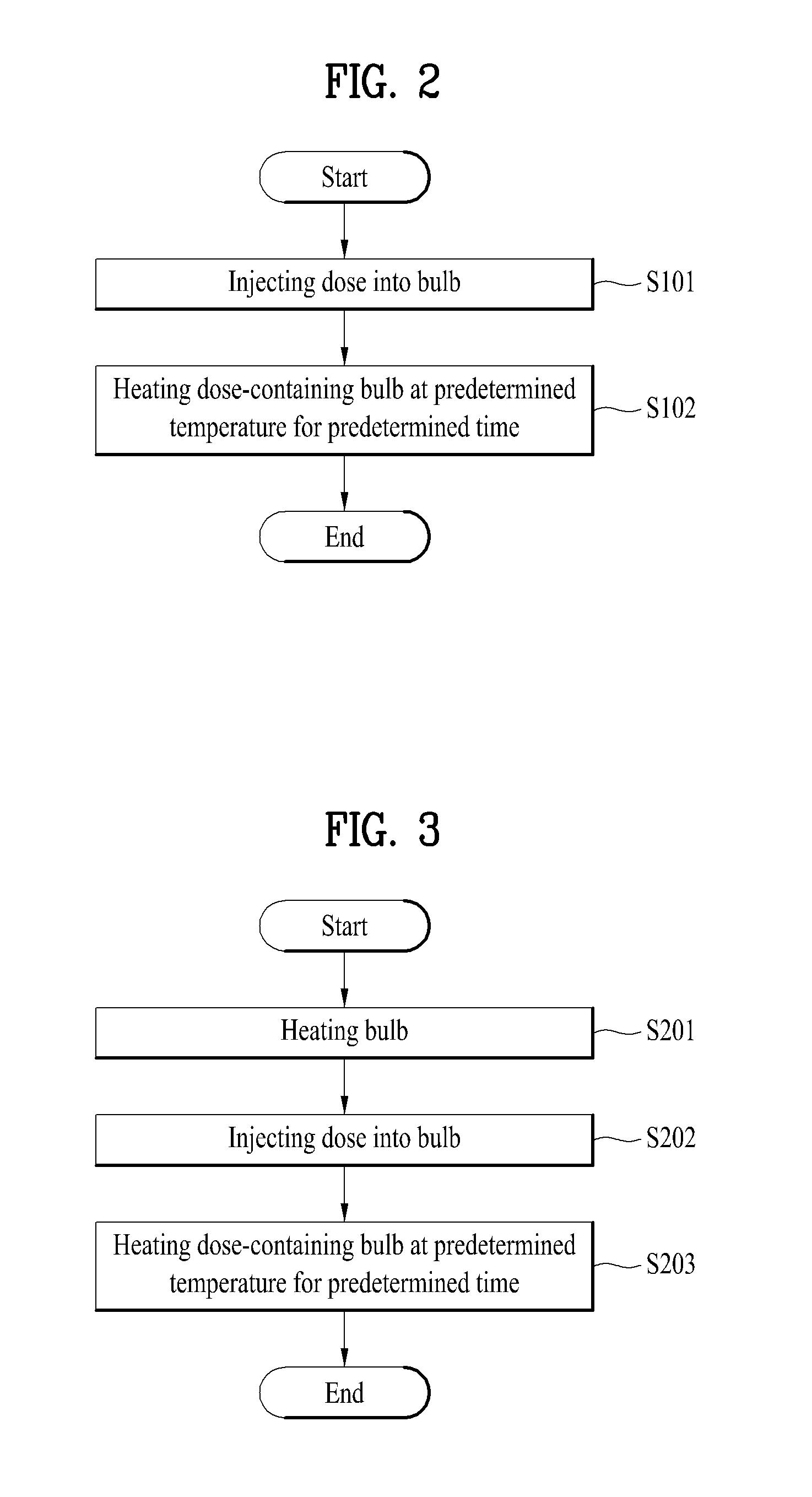

Electrodeless lighting device and method for manufacturing the same

InactiveUS20140167607A1Improve initial lighting propertyImprove luminous efficiencyTube/lamp vessel fillingVessels or leading-in conductors manufactureEffect lightEngineering

An electrodeless lighting device and methods for manufacturing the same are provided. The method includes inserting a dose into the bulb and at least one of heating a vacuum line for applying a vacuum to the bulb at first predetermined temperature and heating the bulb containing the dose at a second predetermined temperature for a predetermined time.

Owner:LG ELECTRONICS INC

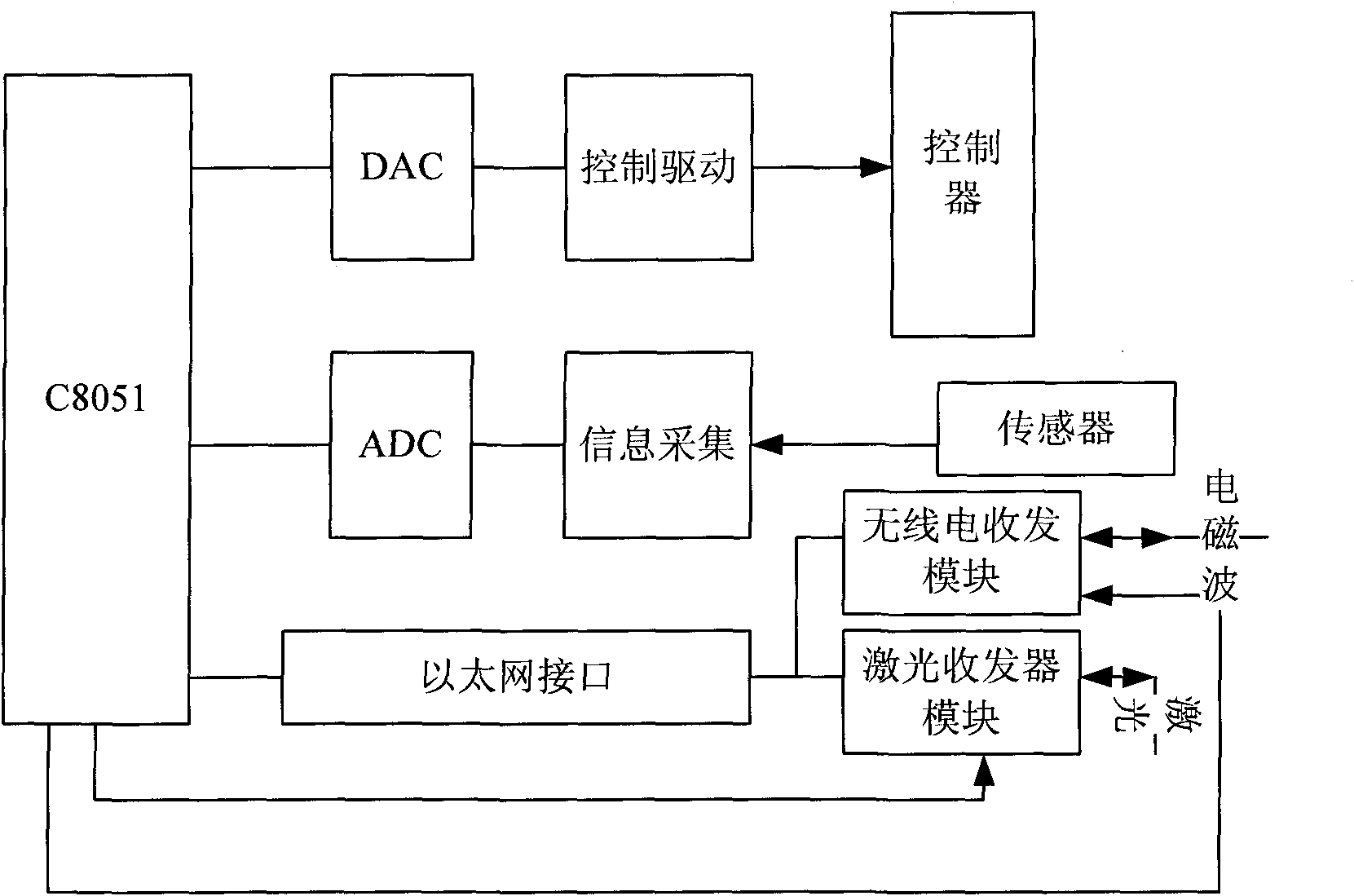

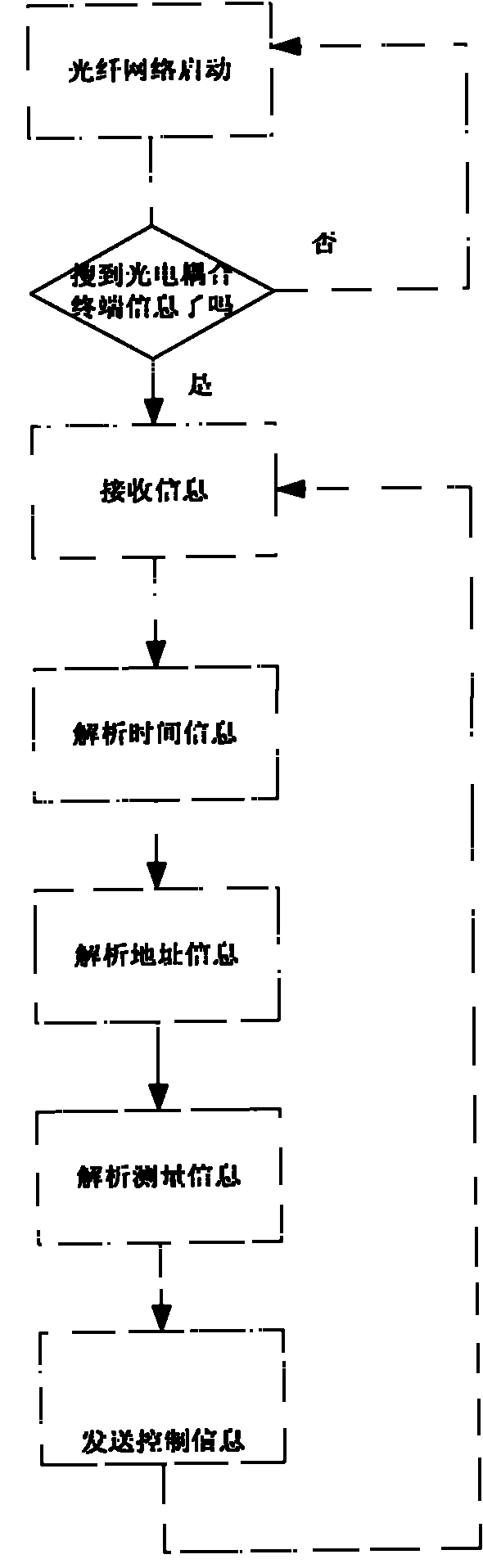

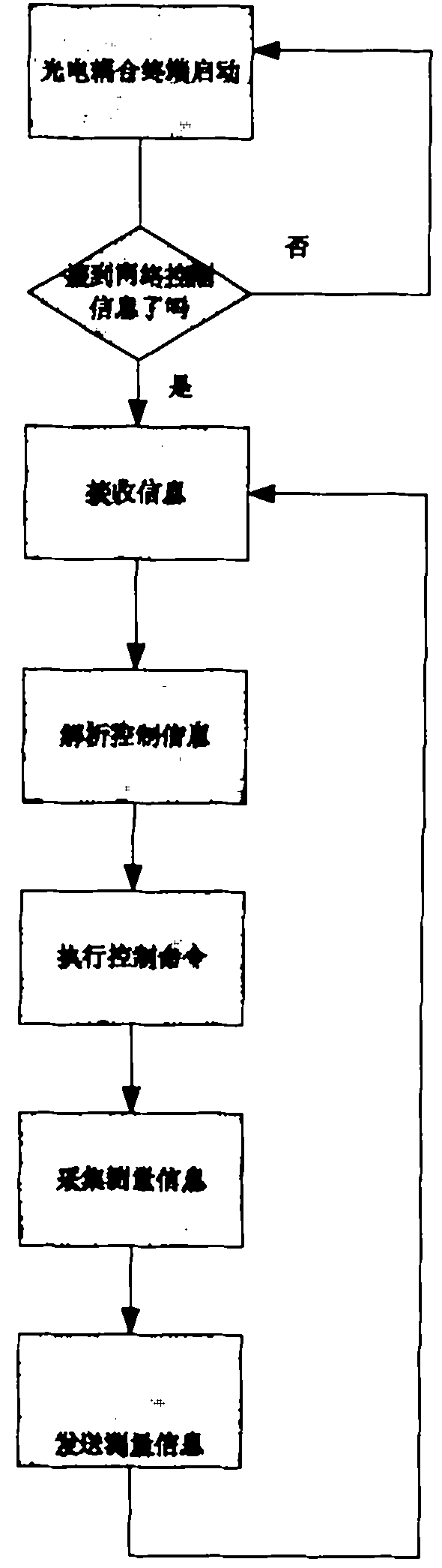

Photoelectrical coupling type terminal device

InactiveCN101833312AImprove exchange capacityOvercome power supply challengesData switching by path configurationElectromagnetic transmissionTransceiverFrequency spectrum

The invention relates to a photoelectrical coupling type terminal device characterized in that a terminal computer C8051 collects information through an ADC (Analog to Digital Converter) module, a wireless receiving and transmitting module and a laser transceiver module are used for communication through multi-frequency spectrum wireless photoelectrical signals and an optical network to transmit measuring information to a control center and then are used for communication through the multi-frequency spectrum wireless photoelectrical signals and the optical network to transmit the control information of the control center to the terminal computer C8051, and then the terminal computer C8051 inputs the information for control through a DAC (Digital-to-Analog Converter) module. The device can overcome the defects of coupling simplicity and immovability of the current terminal information and strengthen the exchange capacity of network information so that a bus can be measured and controlled through various kinds of media information to form a mobile network measuring and control bus.

Owner:HARBIN ENG UNIV

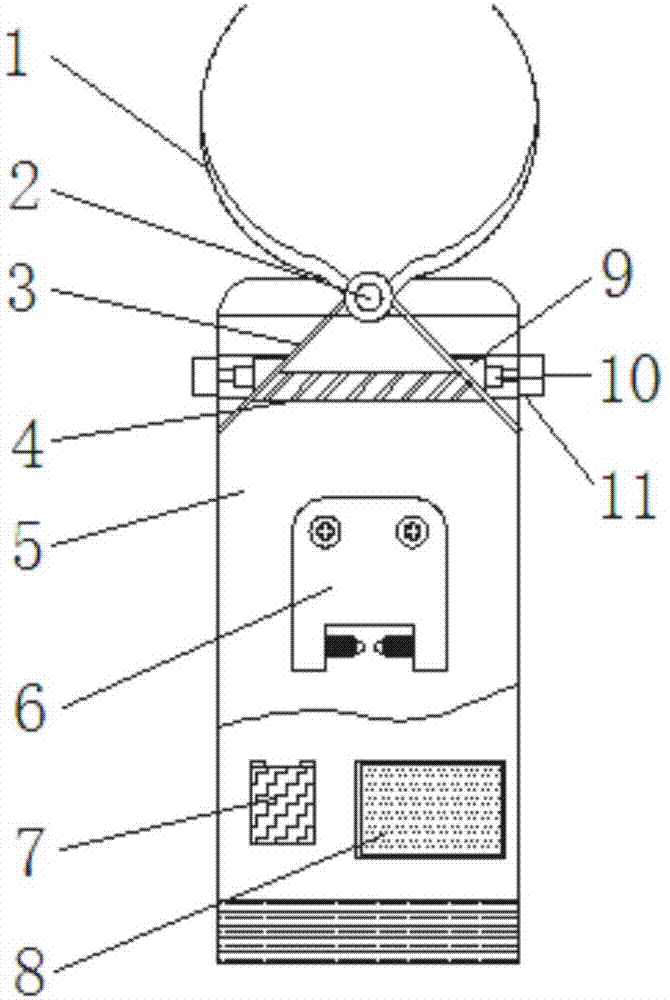

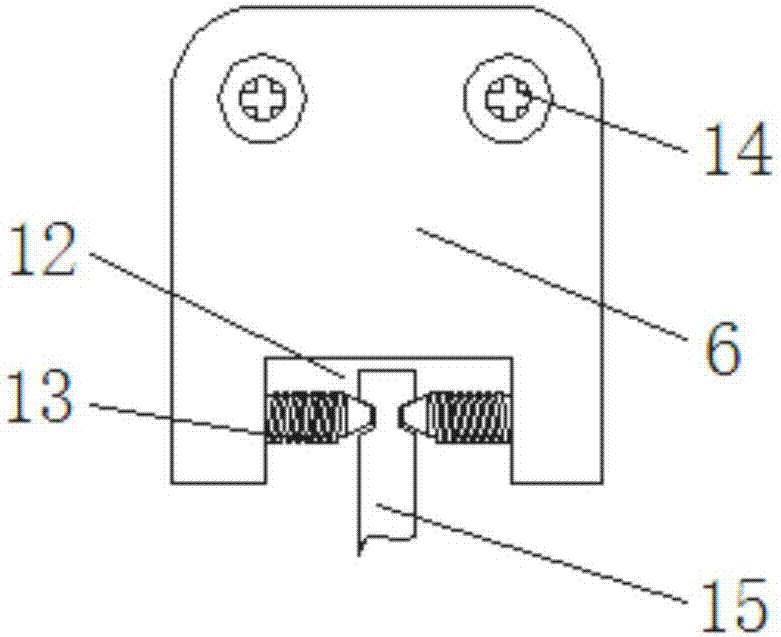

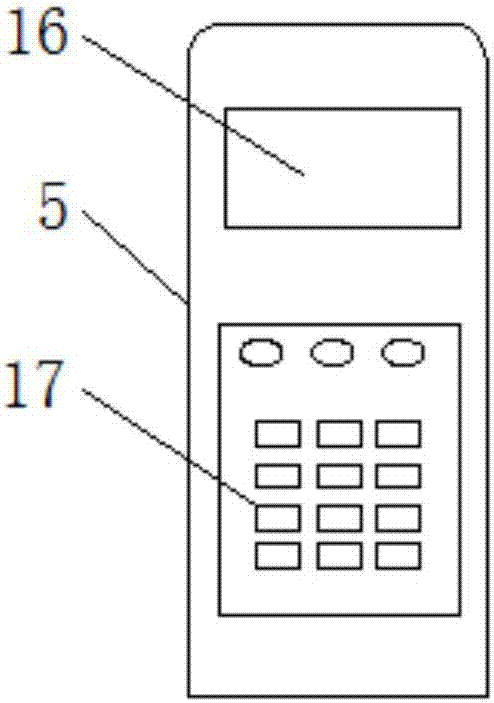

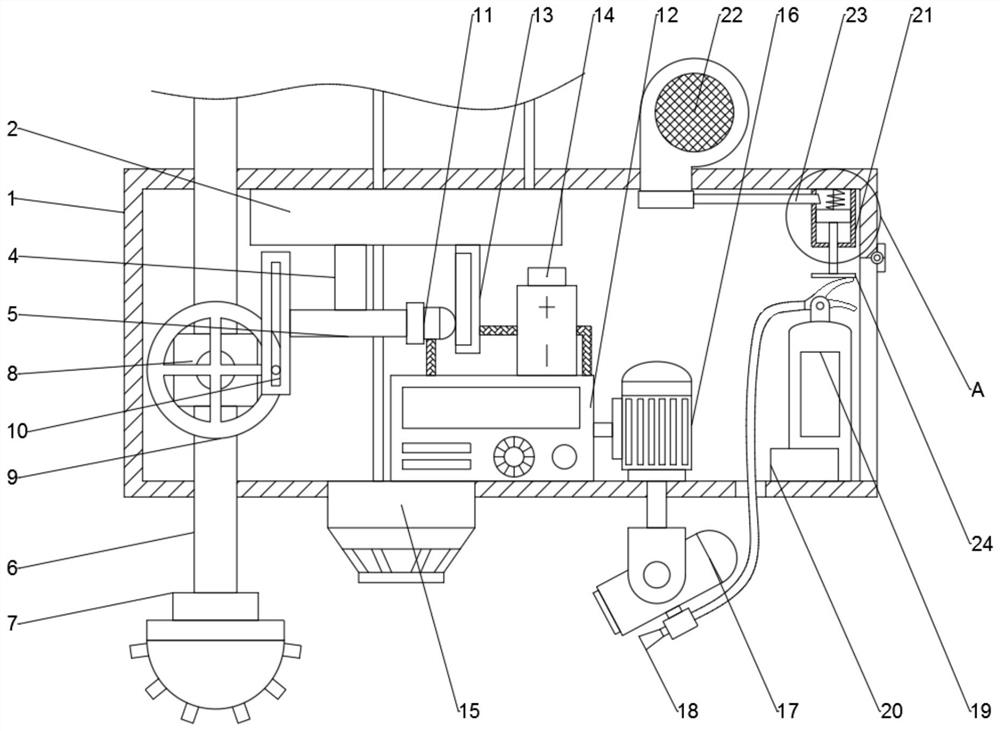

Portable electric leakage safety detection device

InactiveCN107390013AEasy to useImprove securityElectrical testingCurrent measurements onlyComputer moduleElectric shock

The invention discloses a portable electric leakage safety detection device. The portable electric leakage safety detection device comprises a device body, a wire clamp is connected to the top of the device body through a rotary knob, supporting arms are symmetrically arranged at the lower end of the rotary knob in a clamping mode, a restoration spring is connected between the two supporting arms, and a transformation module is arranged at one side of the bottom inside the device body. According to the portable electric leakage safety detection device, high voltage is generated mainly through the transformation module, then the wire clamp is clamped on the part to be detected of a cable, whether electric leakage occurs on the part or not is judged through a flowing current value, when the wire clamp is clamped on the cable, the rotary knob is clamped in a toothed groove, when the detection device is not in use, the wire clamp does not need to be held by the hand, the possibility of an electric shock is reduced, a connecting buckle is further arranged at the back of the detection device, an insulating telescopic rod can be inserted on the connecting buckle in a clamping mode, and in this way, when some high wire sections and dangerous wire sections are detected, since the sections are far away from the human body, the portable electric leakage safety detection device is safer.

Owner:CHENGDU ZHONGFU LIXIANG TECH

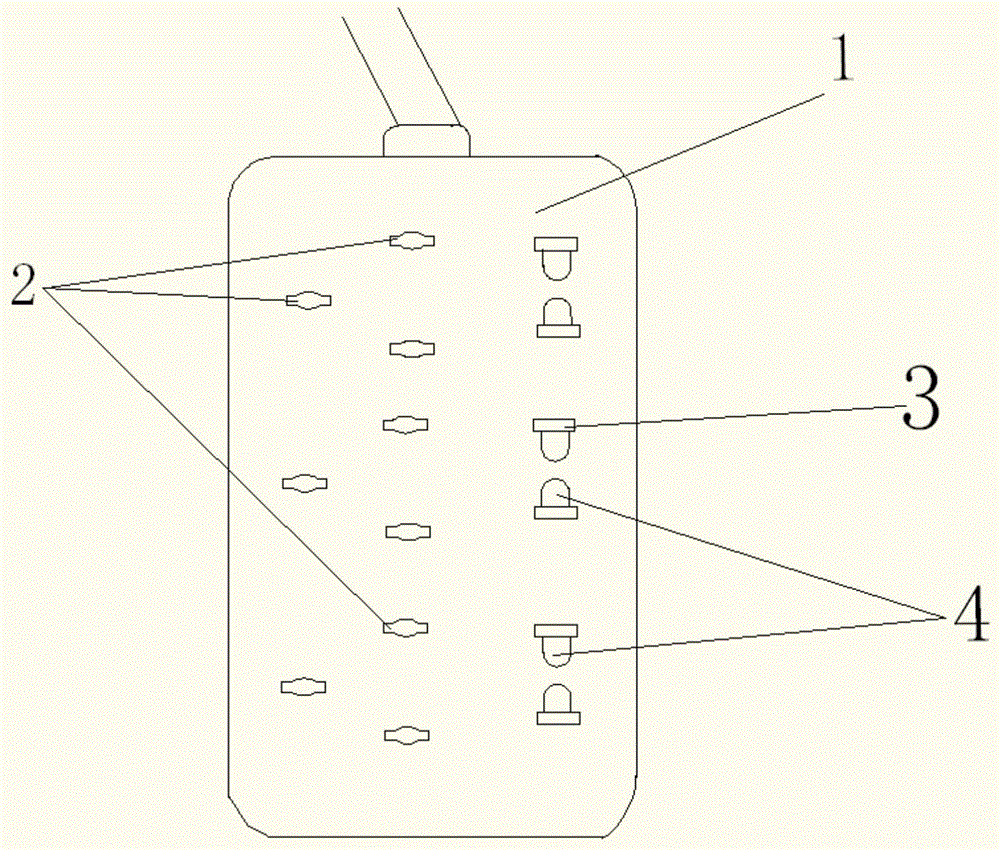

Locking socket capable of fixing plug connecting wire

InactiveCN104393447AEasy to usePlay a release effectLive contact access preventionEngineeringElectric shock

The invention relates to a locking socket capable of fixing a plug connecting wire. The locking socket comprises a socket base with at least two power jacks; a locking device is arranged under the power jacks, and comprises a supporting structure and a fastener arranged on the supporting structure. The locking socket capable of fixing the plug connecting wire has the beneficial effects that a power wire is fixed on the locking device when the plug and the socket are used, and then the power wire can be locked conveniently and safety accidents such as electric shock can be reduced; the locking socket is simple in structure, and safe and convenient to use, and has certain market prospect.

Owner:陈伟群

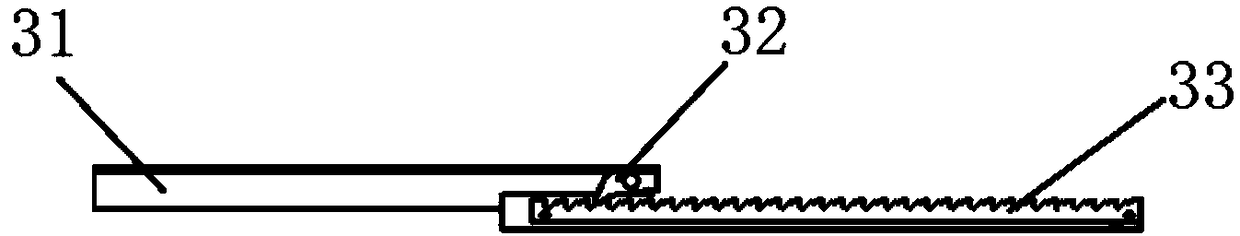

High-voltage insulation contact

ActiveCN104240873AIncrease working lengthReduce electric shockInsulating bodiesMetallic materialsEngineering

A high-voltage insulation contact comprises a working portion which comprises an extending portion and a working end connected to the extending portion, the extending portion is composed of multiple telescopic barrels in a nested mode, the diameters of the telescopic barrels are gradually reduced, and the telescopic barrels and the working end are made of metal. According to the high-voltage insulation contact, the extending section of the working portion can stretch out and draw back freely, working length is increased, an operator can remotely operate the high-voltage insulation contact, and the possibility of electric shock is reduced. The working portion and an insulation portion can relatively rotate freely by certain angles, and the high-voltage insulation contact is convenient to use, simple in structure and especially suitable for hot-line work at natural hazard places or accident sites.

Owner:STATE GRID CORP OF CHINA +1

Fire alarm for municipal engineering construction

InactiveCN112419649AReduce electric shockShorten the timeFire rescueFire alarm electric actuationEnvironmental resource managementFire - disasters

The invention discloses a fire alarm for municipal engineering construction. The fire alarm comprises a central processing unit and an external box body, a water spraying mechanism, a smoke alarm, a camera and a dry powder extinguisher are arranged in the external box body, the smoke alarm is fixedly connected with the external box body, and the smoke alarm is electrically connected with the central processing unit. According to the fire alarm for municipal engineering construction, through cooperation of the central processing unit, the water spraying mechanism, the smoke alarm, the camera, arotating piece, a control mechanism, the dry powder extinguisher and other mechanisms, when a fire occurs, whether a circuit catches fire or not can be judged firstly, then water spraying or dry powder spraying is decided, and the possibility of electric shock is reduced; and moreover, professionals can remotely control the fire extinguisher to spray dry powder, so that the time is saved, the fire can be accurately controlled, and the problems that electric power is possibly leaked when water is directly sprayed in case of a fire, the danger of electric shock of people is increased and the rescue difficulty is increased are solved.

Owner:邹永洋

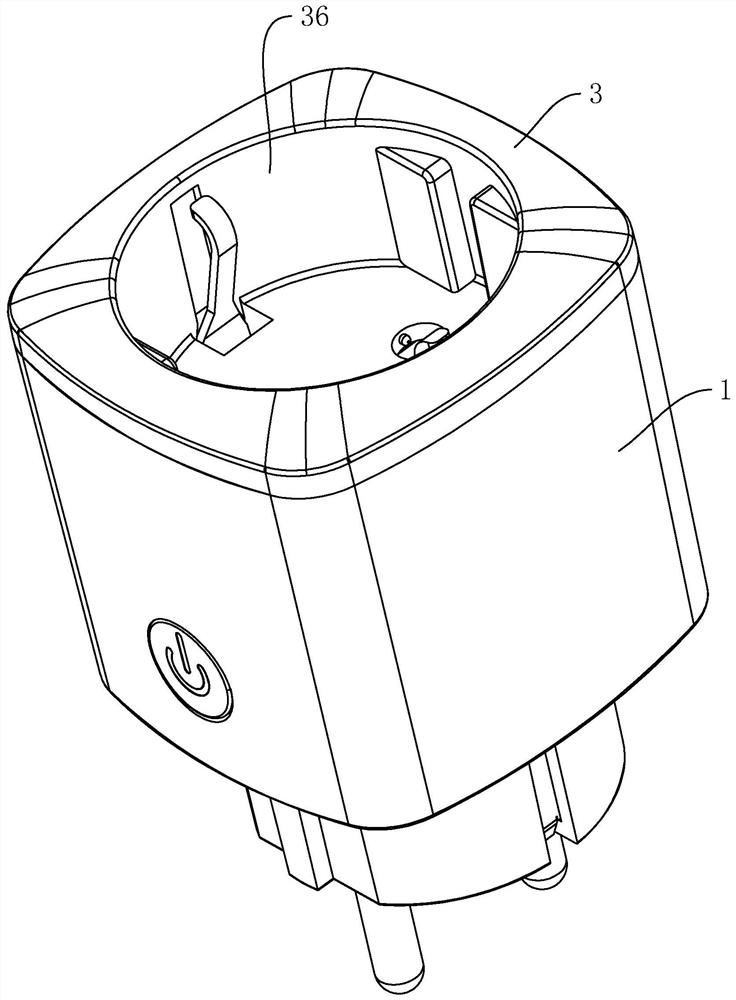

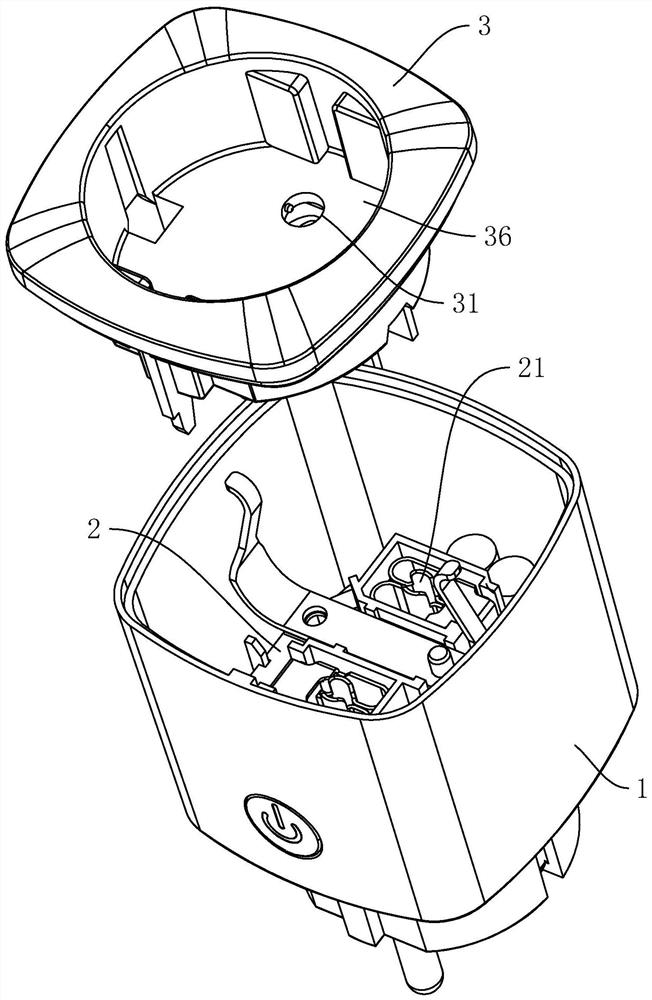

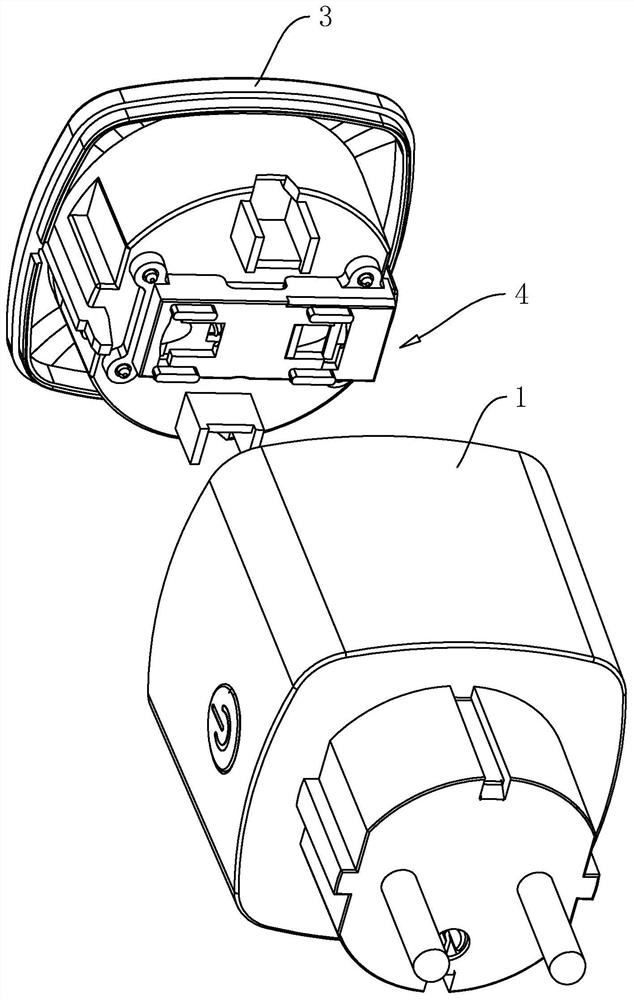

Intelligent socket with child protection function

ActiveCN112803189AImprove securityReduce electric shockCoupling device detailsElectrical connectionStructural engineering

The invention relates to an intelligent socket with a child protection function, and relates to the field of sockets. The intelligent socket comprises a lower shell, a circuit board arranged in the lower shell and an upper shell covering one side of the lower shell. The upper shell is provided with two electrode jacks, the circuit board is electrically connected with terminal metal contact pieces in one-to-one correspondence with the electrode jacks, a protection assembly arranged between the electrode jacks and the terminal metal contact pieces is included, the protection assembly comprises a partition plate and a limiting cover, the partition plate is connected to one side, close to the terminal metal contact pieces, of the upper shell in a sliding mode, the limiting cover is fixed to one side, close to the terminal metal contact pieces, of the upper shell, and a sliding cavity for the partition plate to slide is formed between the limiting cover and the upper shell; and the partition plate is provided with guide surfaces in one-to-one correspondence with the electrode jacks, and the limiting cover is provided with two through holes in one-to-one correspondence with the electrodes and allowing the electrodes to penetrate through. The socket has the advantages that the metal contact pieces are isolated, the occurrence of electric shock of children when the children insert things into the jacks is reduced, and the use safety of the socket is improved.

Owner:NINGBO CHUANGGUAN ELECTRIC APPLIANCE CO LTD

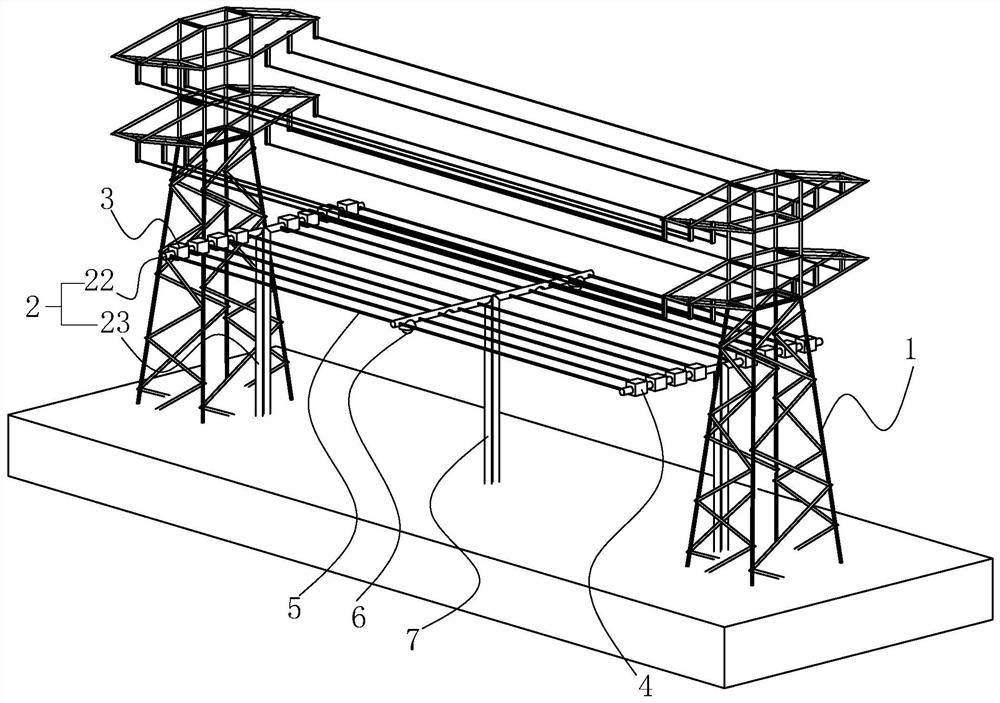

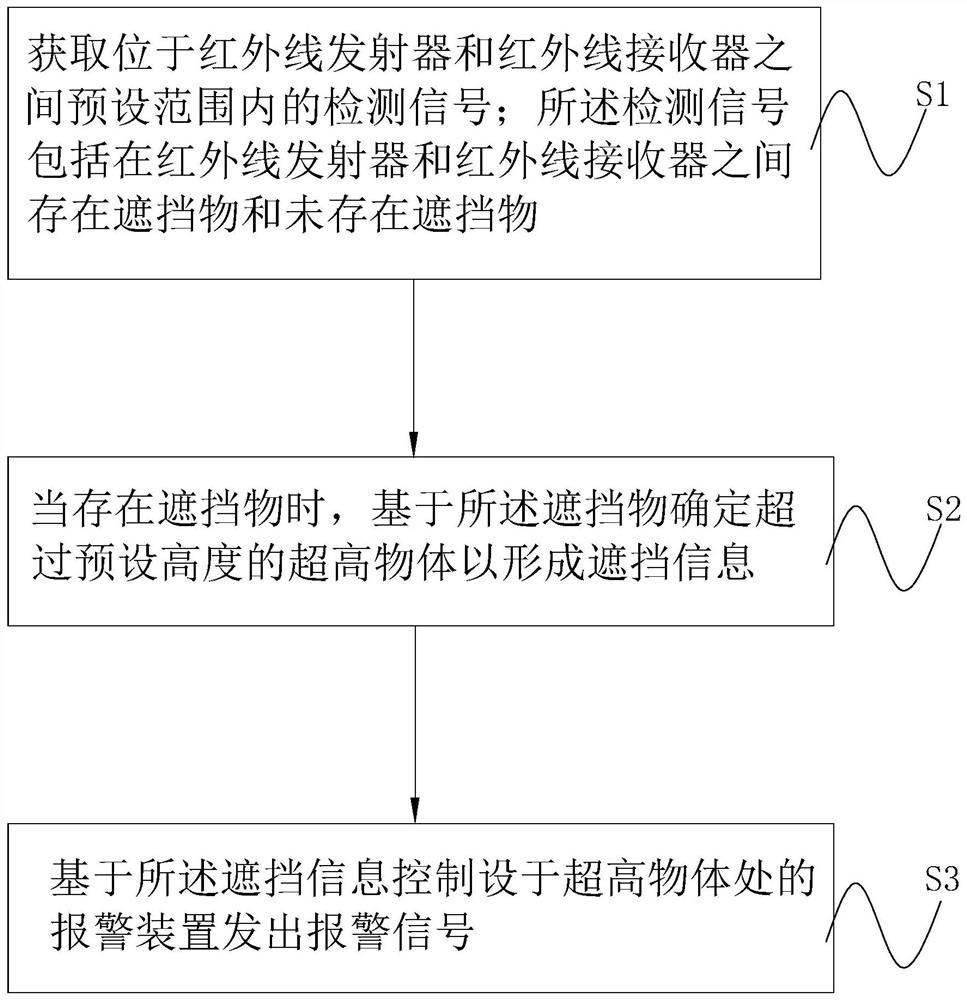

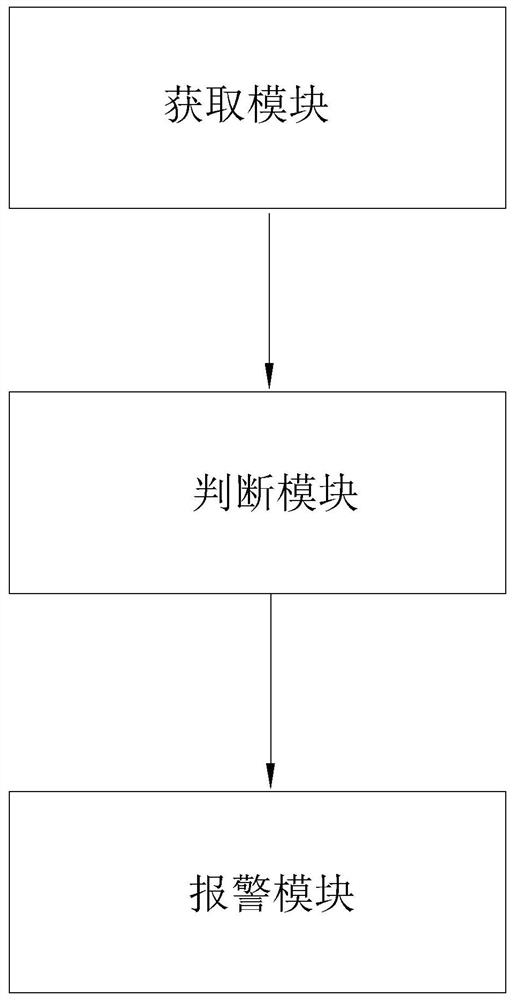

Early warning protection method and system under high-voltage line, computer equipment and storage medium thereof

ActiveCN112288996AEnsure safetyDifficult to touchMeasurement devicesCharacter and pattern recognitionInformation controlElectric shock

The invention relates to an early warning protection method and system under a high-voltage line, computer equipment and a storage medium thereof. The early warning protection method comprises the following steps: acquiring a detection signal located in a preset range between an infrared emitter and an infrared receiver; when a shielding object exists, determining an ultrahigh object exceeding a preset height based on the shielding object to form shielding information; and controlling an alarm device arranged at the ultrahigh object to send out an alarm signal based on the shielding information. The signal transmitted by the infrared transmitter is shielded by an object, so that the infrared receiver cannot receive the signal transmitted by the infrared transmitter, an ultrahigh object which enters a preset range and exceeds a preset height is determined according to the generated shielding information, and the alarm device sends the alarm signal. Therefore, the ultrahigh object is reminded to exit from the preset protection area of an electric iron tower, the ultrahigh object is not prone to colliding with a high-voltage line, safety of site construction to the electric iron toweris guaranteed, and electric shock accidents are reduced.

Owner:CRPCEC SHENZHEN ENG +1

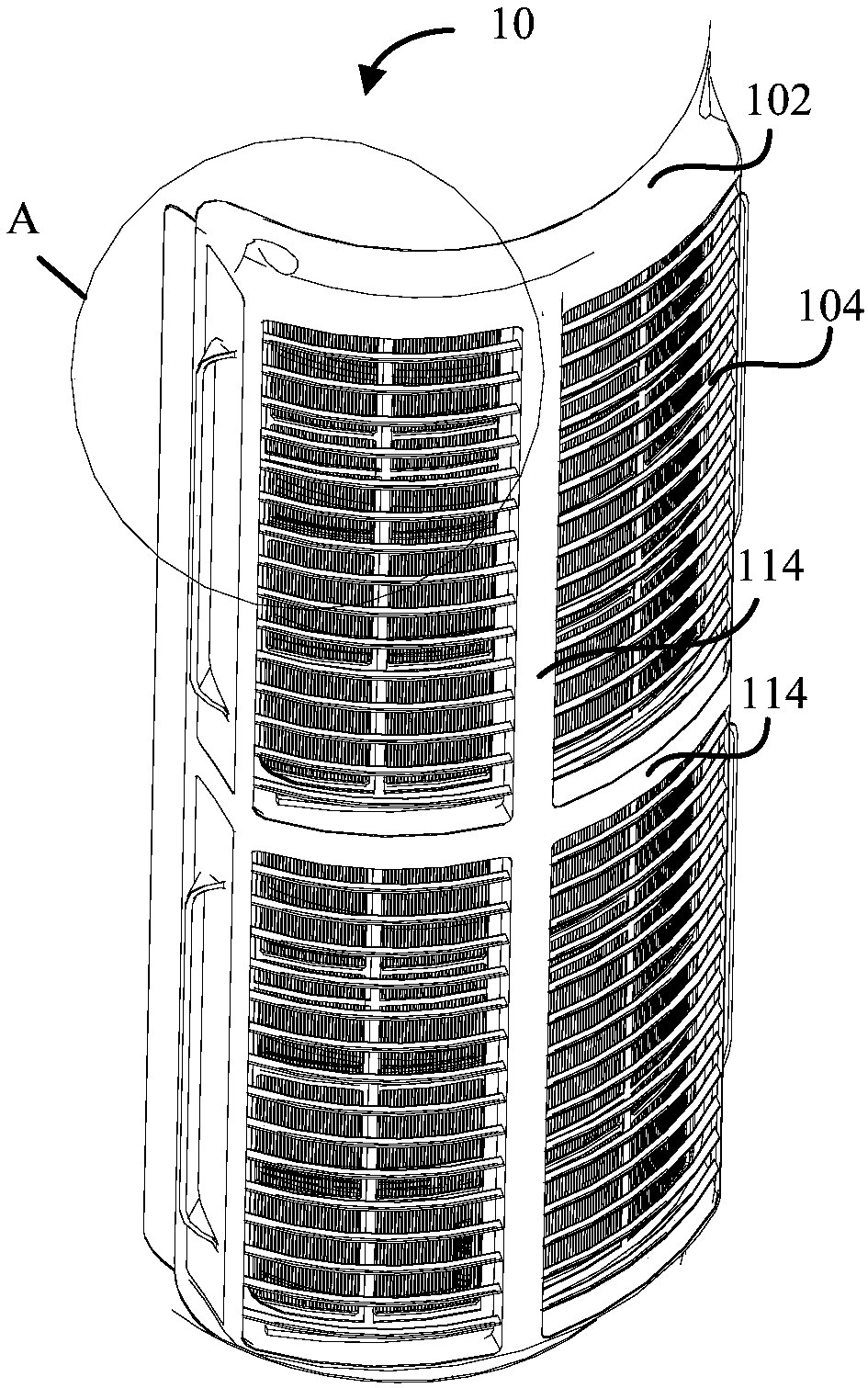

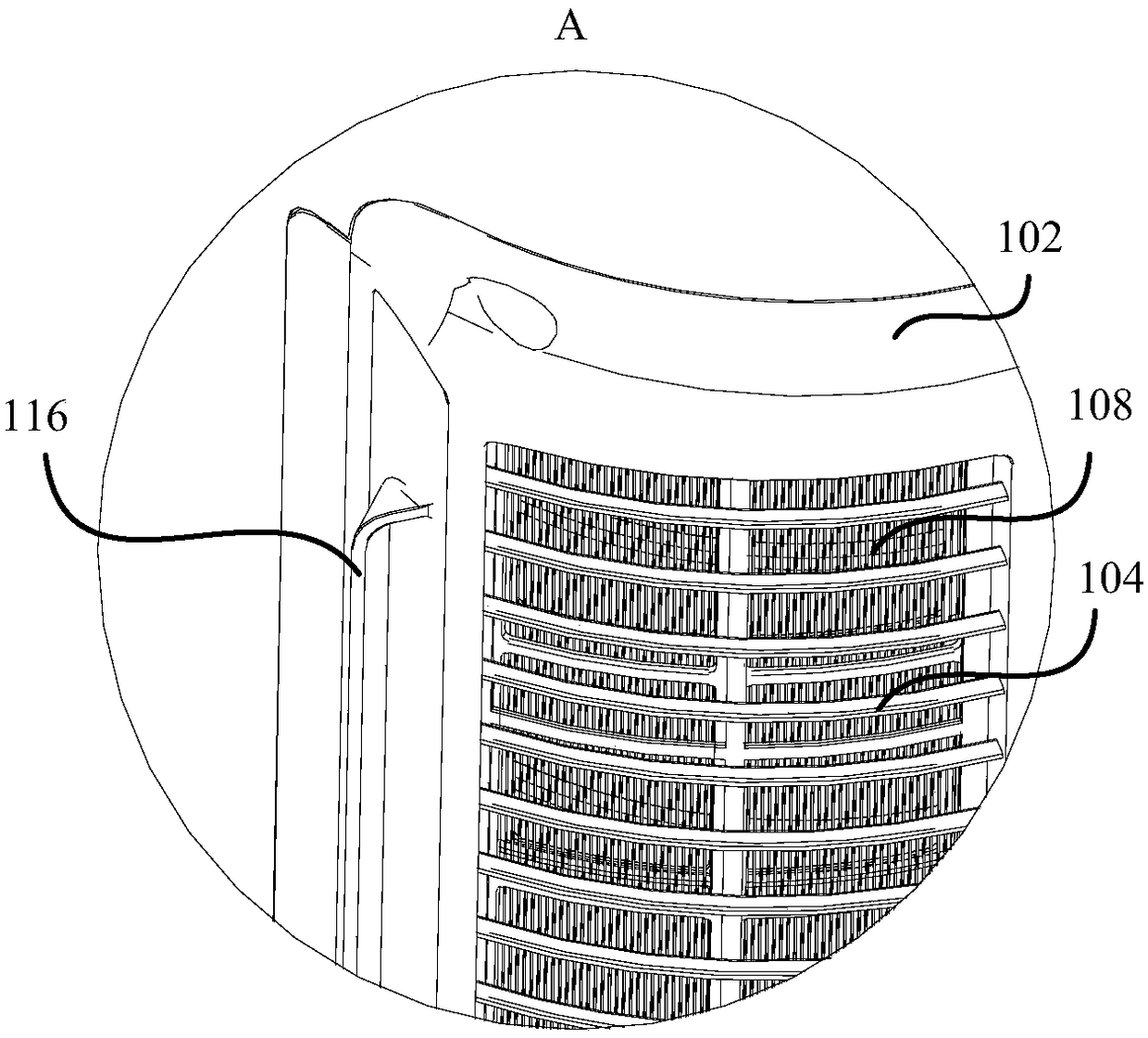

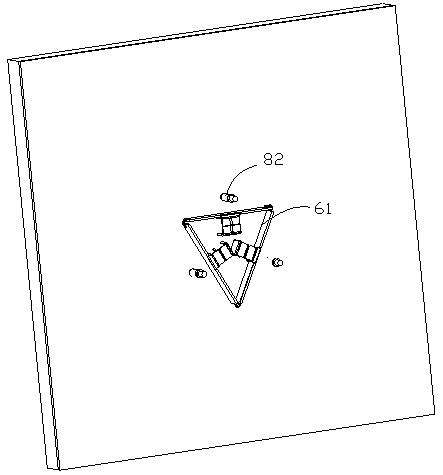

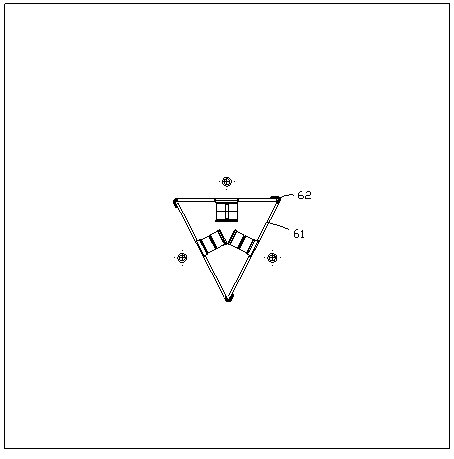

Purification module and air conditioner

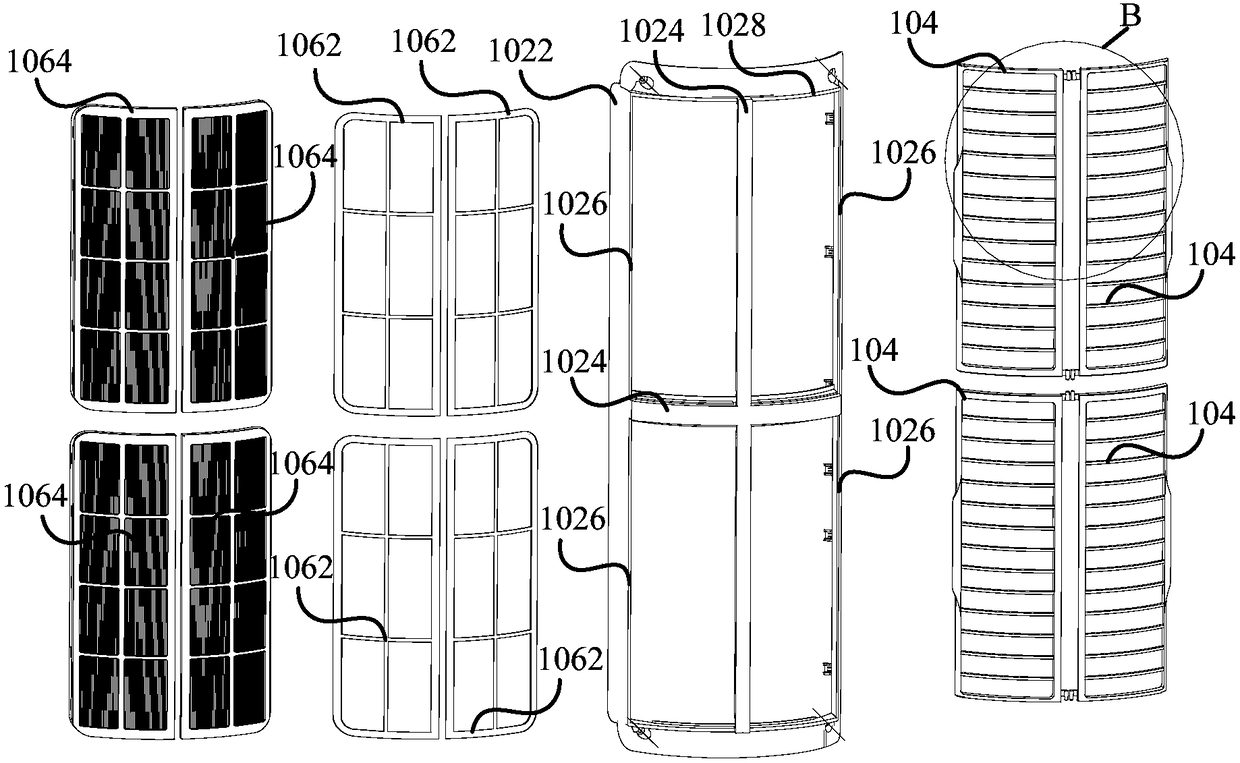

PendingCN108302750AEasy to operateLow costMechanical apparatusCondensate preventionEngineeringSupport plane

The invention provides a purification module and an air conditioner. The purification module comprises a support frame, a grille assembly, one or more mounting openings and one or more purification module bodies, wherein the grille assembly is arranged on an air inlet face of the support frame; each mounting opening is formed in the side face, connected with the air inlet face, in the support frame; each purification module body is arranged in a containing cavity which is defined by the air inlet face and the corresponding side face; and all the purification module bodies cover the ventilatingarea of the support frame so that air can pass through the support frame through the purification module bodies. According to the purification module and the air conditioner, the purification modulebodies in the purification module are convenient to mount and dismount, and the purification module bodies can be taken out conveniently to be replaced or repaired or maintained, so that purificationperformance of the purification module is more stable. When any purification module body breaks down, only the corresponding purification module body needs to be replaced, and the whole purification module does not need to be replaced, so that the repair or maintenance cost is lower.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

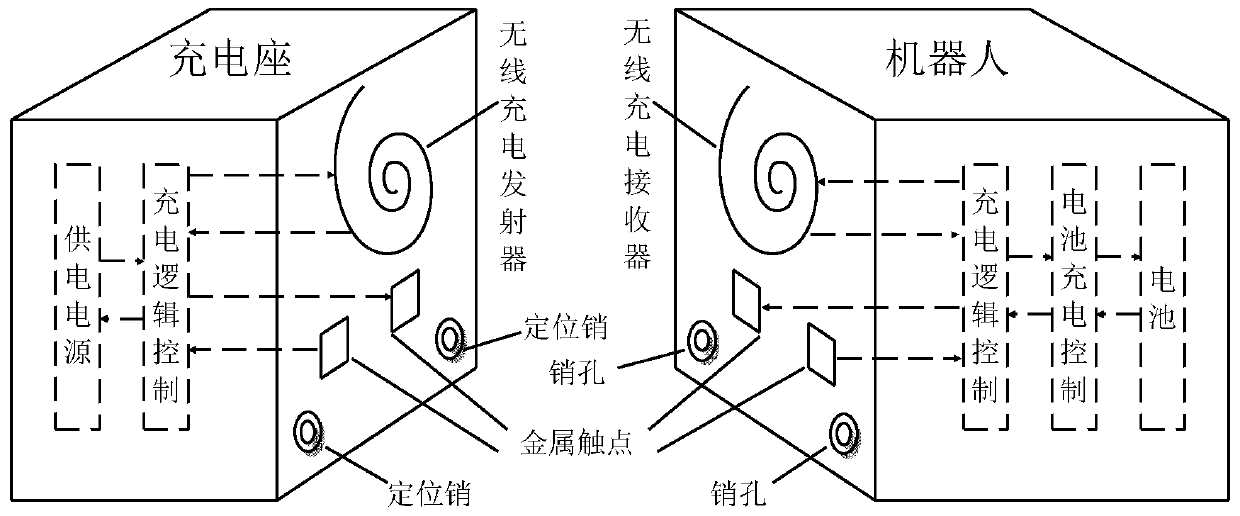

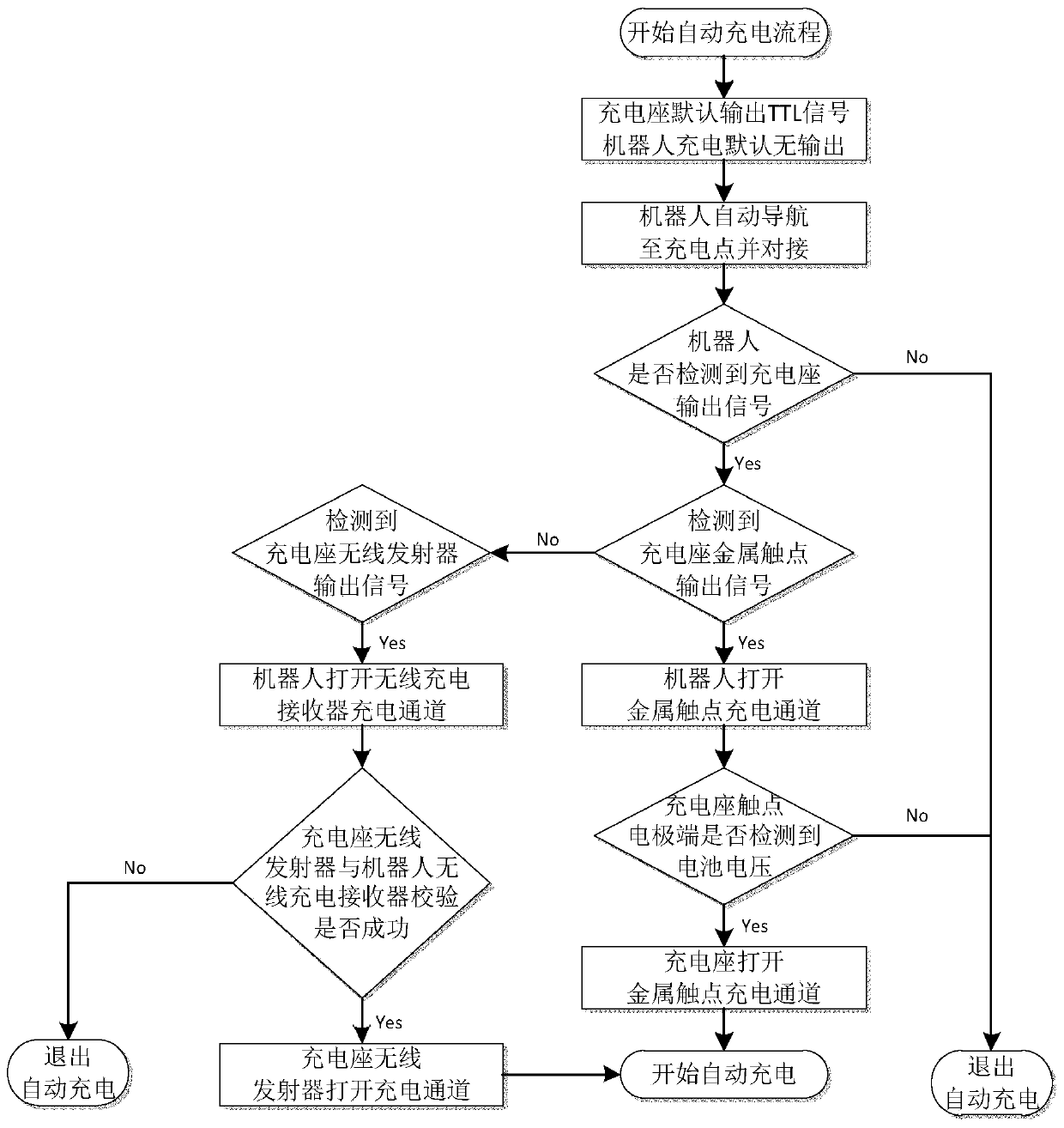

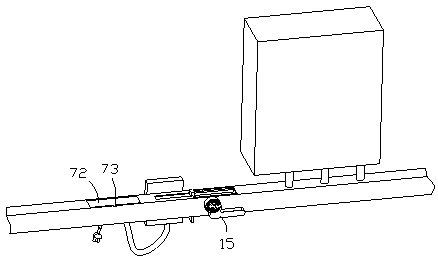

Intelligent control automatic charging system and method used by robot

ActiveCN109768607AFast chargingReduce the risk of agingBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

The invention belongs to the technical field of robots, and particularly relates to an intelligent control automatic charging system and method used by a robot. According to the scheme, the advantagesand disadvantages of metal contact touching charging / wireless charging are integrated, the alignment accuracy of charging contacts is improved, the risk of electric shock or spark caused by the touching of the contacts is reduced, the advantages that the metal contact touching charging has high efficiency and the wireless charging has a high connection speed can be exerted, the charging connection mode can be automatically identified, the intelligent control of the metal contact touching charging / wireless charging can be realized according to the scene requirements, and a battery charging curve can be reasonably dynamically controlled to reduce the charging loss.

Owner:广州高新兴机器人有限公司

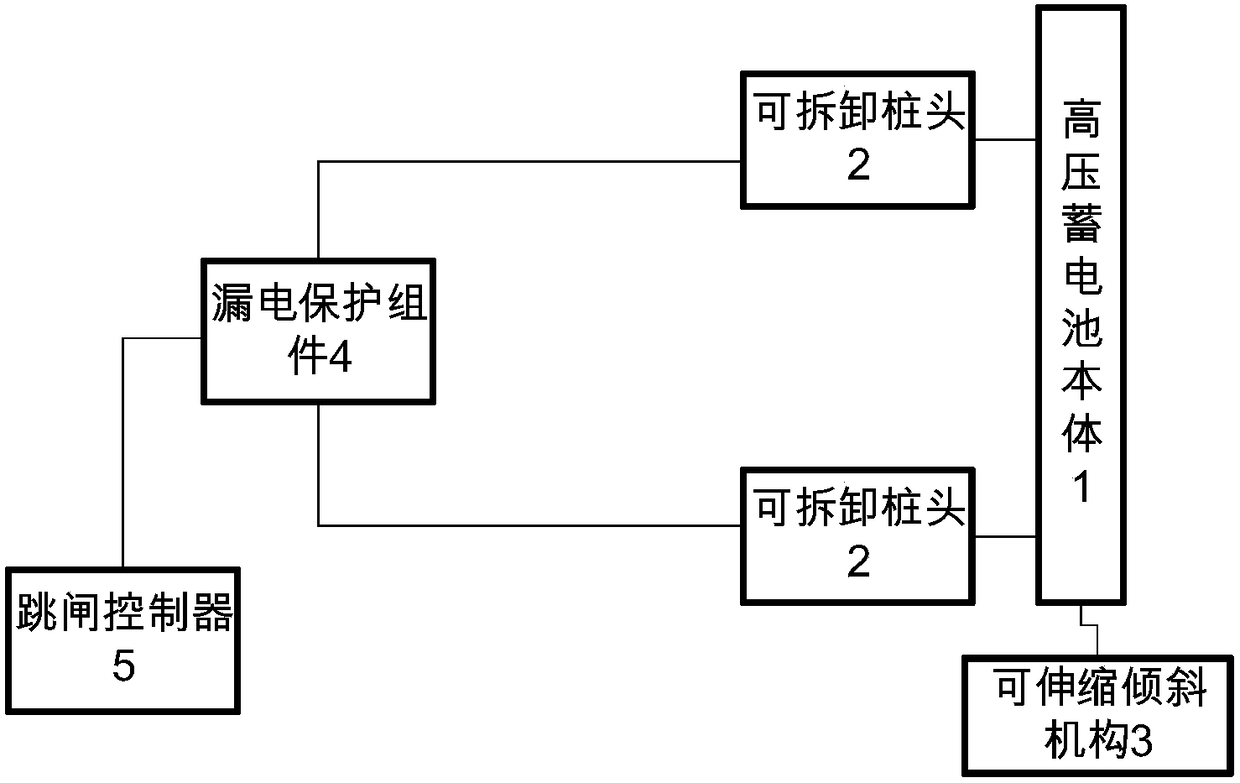

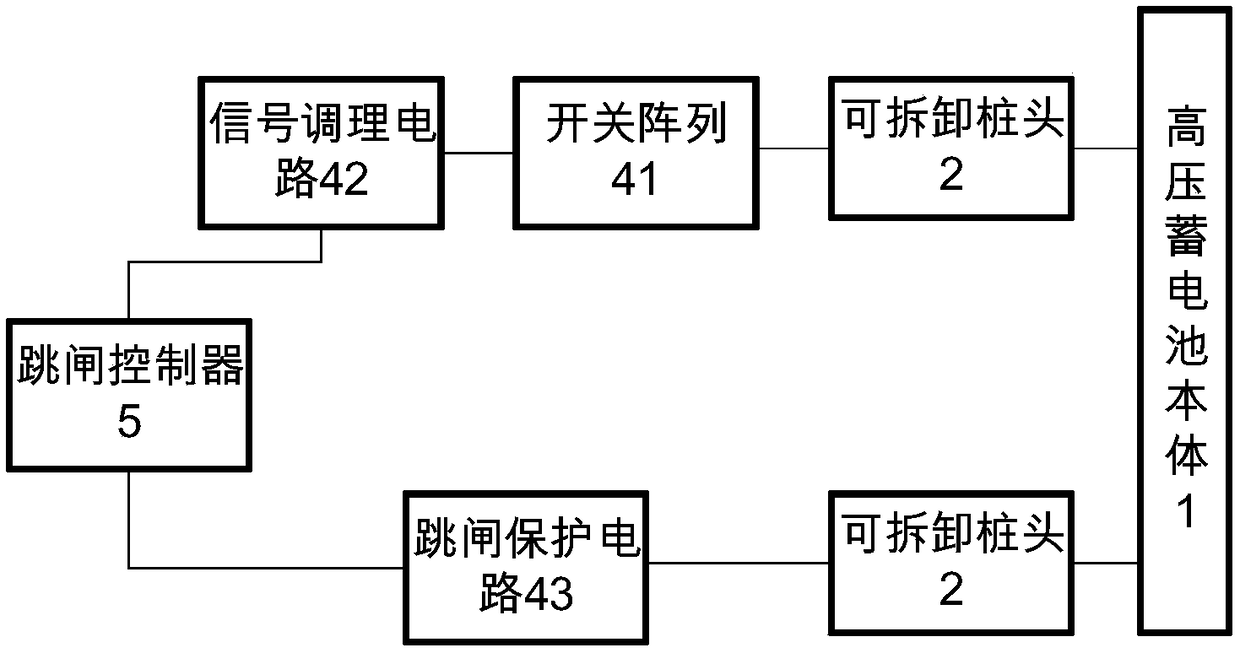

High-voltage battery system easy to replace

InactiveCN108237935AEasy to replaceAvoid life threateningCharging stationsElectric propulsion mountingHigh voltage batteryEngineering

The invention relates to a high-voltage battery system easy to replace, and the rapid replacement of a high-voltage battery in an electric car can be realized by coordinating with a shared battery base station. The high-voltage battery system comprises a detachable high-voltage battery module and a leakage protection module, wherein the detachable high-voltage battery module is arranged in the electric car and used for supplying power to the electric car; and the leakage protection module is arranged in the electric car and connected with the detachable high-voltage battery module, and the leakage protection module is used for ensuring the safety of operators in the process of replacing high-voltage battery. Compared with the prior art, the high-voltage battery system easy to replace has the advantages that replacement is simple, the safety performance is high and time is saved.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

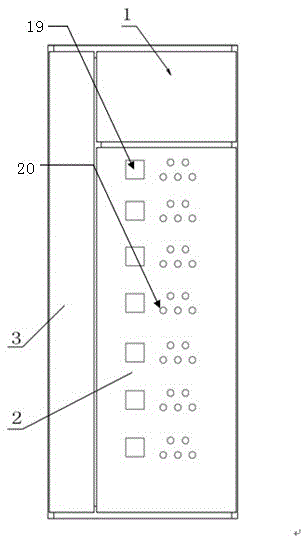

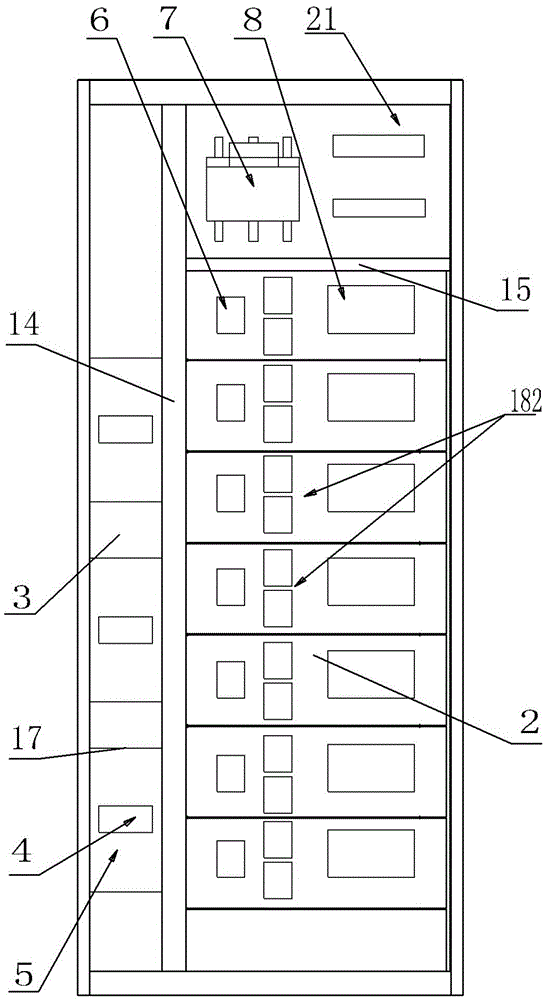

Low-voltage wire-inlet/outlet cabinet and low-voltage wire-inlet/outlet equipment

InactiveCN105576518ABeautiful appearanceReduce electric shockBus-bar/wiring layoutsSubstation/switching arrangement casingsStructural engineeringMechanical engineering

The invention relates to a low-voltage wire-inlet / outlet cabinet and low-voltage wire-inlet / outlet equipment. The low-voltage wire-inlet / outlet cabinet comprises a cabinet body, wherein a wire inlet / outlet chamber partitioning plate for dividing the interior of the cabinet body into a wire inlet chamber and a wire outlet chamber is arranged in the cabinet body; a wire inlet chamber mounting plate is arranged in the wire inlet chamber; a wire outlet chamber mounting plate is arranged in the wire outlet chamber; the wire inlet chamber mounting plate is provided with a wire inlet chamber mounting plate front plate surface for mounting electric appliance elements; a wire inlet chamber routing space for routing is formed between the wire inlet chamber mounting plate and a back side plate of the cabinet body; the wire outlet chamber mounting plate is provided with a wire outlet chamber mounting plate front plate surface for mounting the electric appliance elements; a wire outlet chamber routing space communicated with the wire inlet chamber routing space through a wiring channel is formed between the wire outlet chamber mounting plate and the back side plate of the cabinet body. According to the low-voltage wire-inlet / outlet cabinet, the technical problem of high potential safety hazard caused by a condition that a technical staff is liable to be in contact with a cable in post maintenance and overhaul in the prior art is solved.

Owner:STATE GRID CORP OF CHINA +2

Intelligent charging station based on internet of things communication

ActiveCN110774911AAvoid LeakageReduce electric shockCharging stationsElectric vehicle charging technologyTelecommunicationsElectrical battery

The invention discloses an intelligent charging station based on internet of things communication. The intelligent charging station comprises a host, a mounting rod arranged on a building wall face, multiple charging devices distributed on the mounting rod at intervals, a battery remaining capacity detection module and an APP module, wherein the charging devices are electrically connected with thehost, the battery remaining capacity detection module is used for detecting the remaining capacity of a storage battery of an electric bicycle to be charged and displaying the remaining capacity on the host, the APP module is arranged in mobile electronic equipment and connected with the host through the GPRS network, and the APP module is used for informing the host to charge the corresponding electric bicycle after a client finishes money charging through the APP module. A charging station of the electric bicycle is independent, unified management is carried out, and hidden fire hazards areavoided; the charging station is directly provided with a charging adapter, the quality of each charging adapter is effectively guaranteed, and fire hazards caused by quality problems are avoided; and moreover, the operation can be carried out through the APP, and the operation is more practical and convenient.

Owner:玉环县兴发动力有限公司

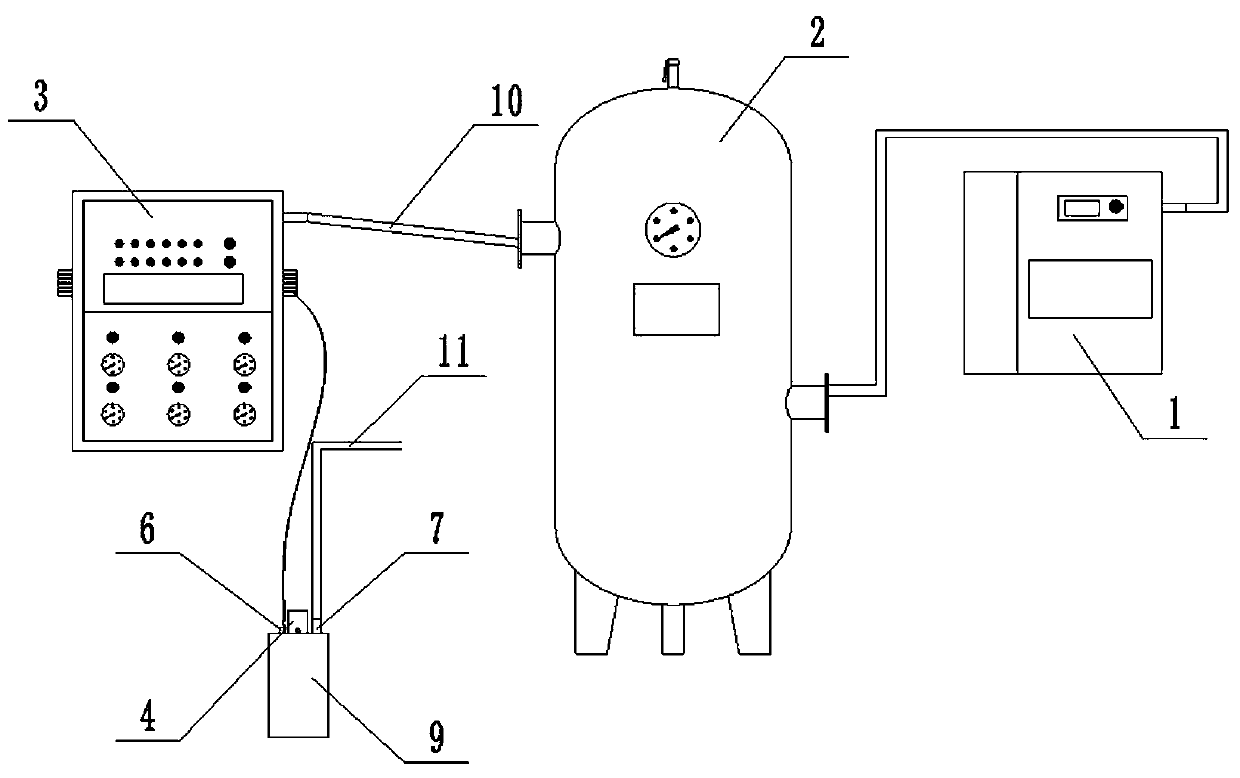

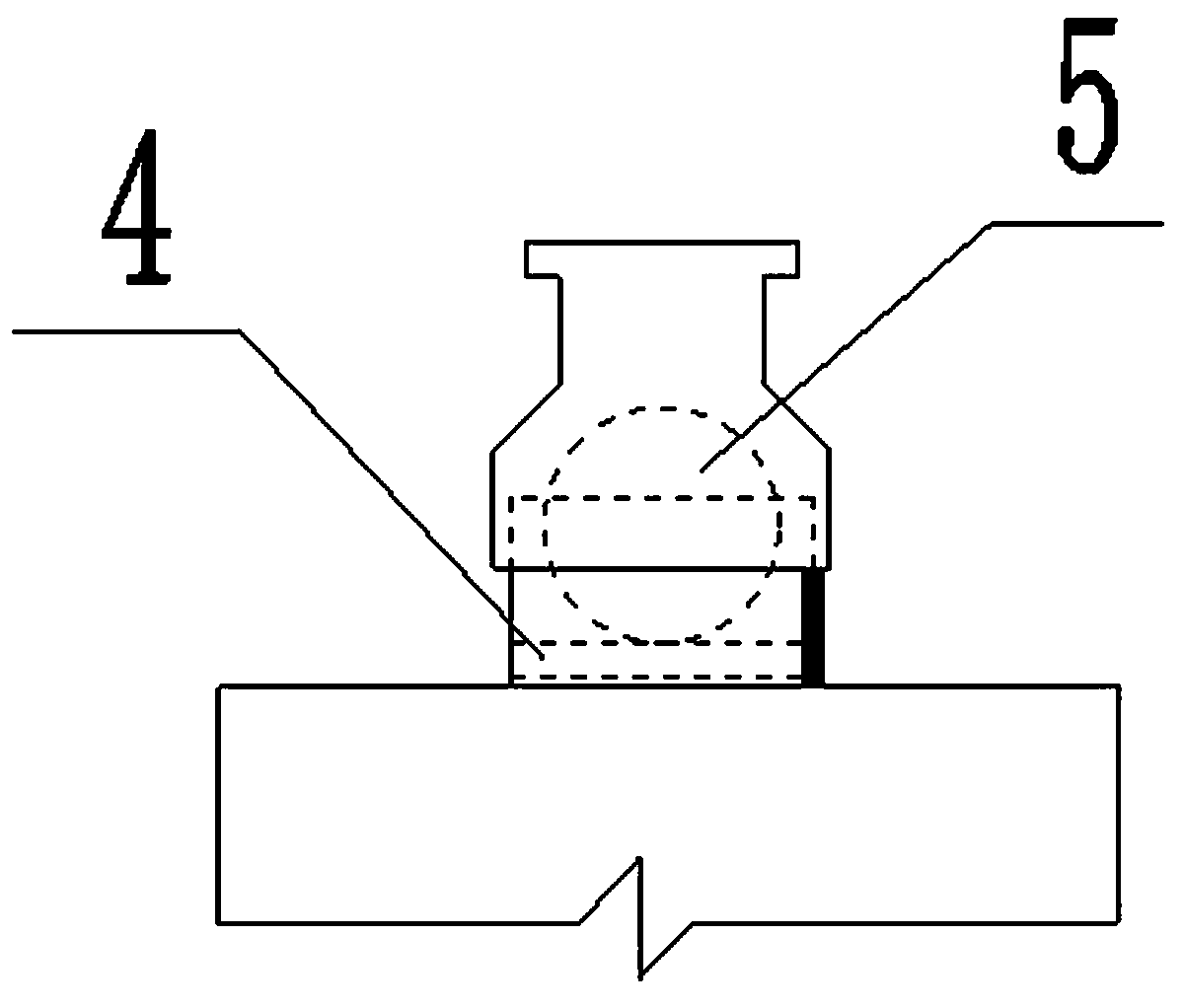

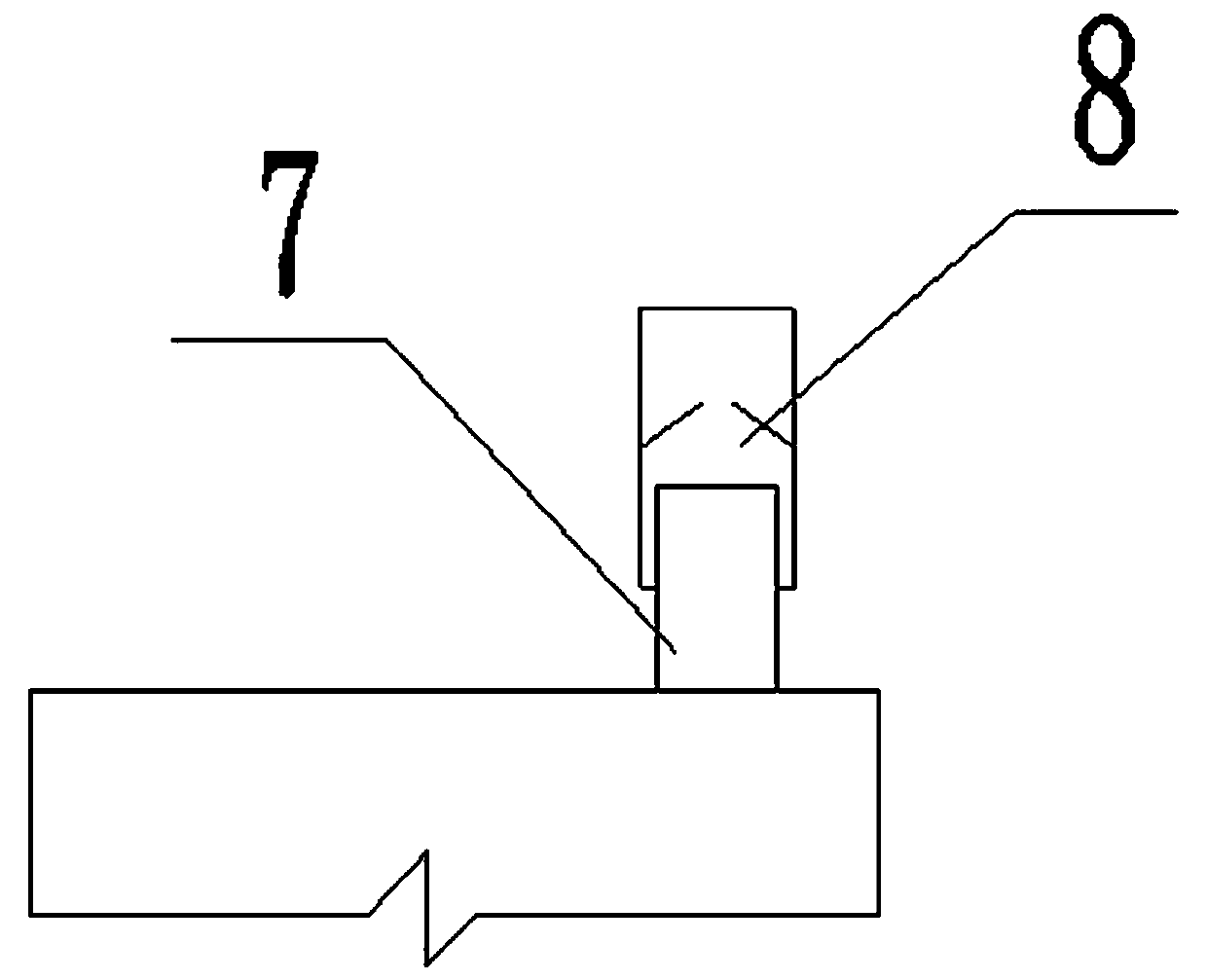

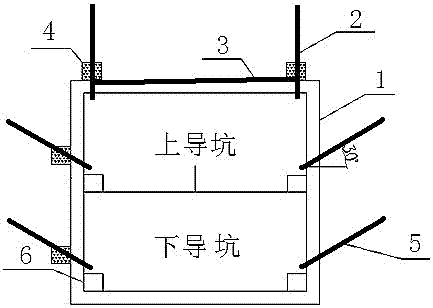

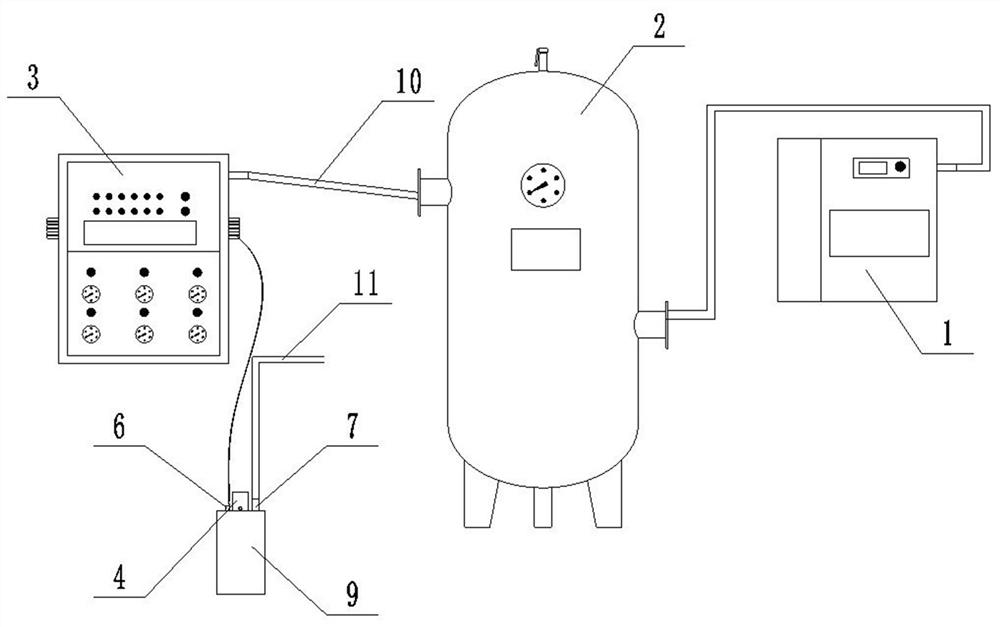

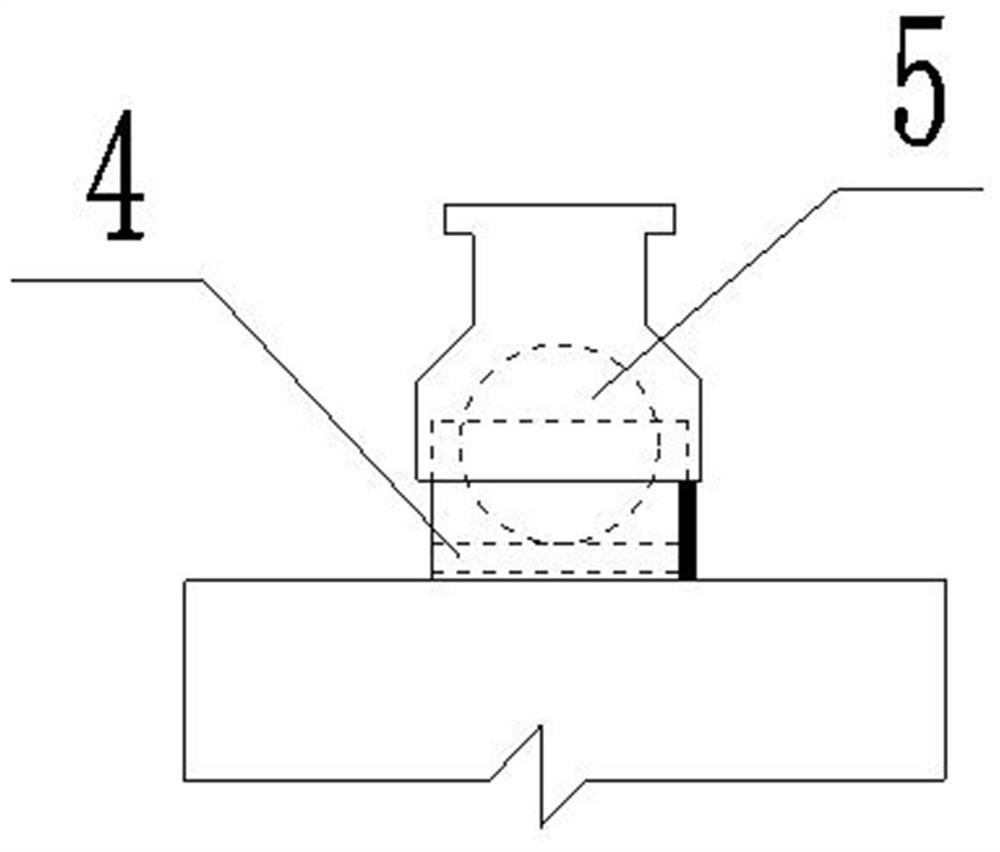

Automatic air pressure drainage kettle device for foundation pit and use method thereof

ActiveCN109811777AAvoid safety issues caused by breakageEnsure electricity safetyFoundation engineeringEngineeringAir compressor

The invention discloses an automatic air pressure drainage kettle device for a foundation pit. The automatic air pressure drainage kettle device comprises an air compressor, an air storage tank, an air pressure control device, a floating bulb stopper, an air inlet, a water outlet, an one-way drainage valve, a drainage kettle, air guide pipes and a water guide pipe; wherein the air compressor, theair storage tank and the air pressure control device are successively connected in series through the air guide pipes; the air pressure control device is connected with the air inlet of the drainage kettle; a water inlet and the water outlet are formed at the upper end of the drainage kettle; the floating bulb stopper is installed in the water inlet; and the one-way drainage valve is installed atthe water outlet and connected with drainage equipment on the foundation pit ground through the water guide pipe. When the invention is in use, only the air guide pipes and the water guide pipe are available in a construction site and a foundation pit drainage well, thereby avoiding safety problems caused by an electric pump dropped into the well and on-site construction machinery incorrectly operated to break an electric wire; and the mutual cooperation between the air pressure control device with automatic adjustment function and the drainage kettle is utilized for realizing the efficient management to the construction site, thereby solving the technical problem.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

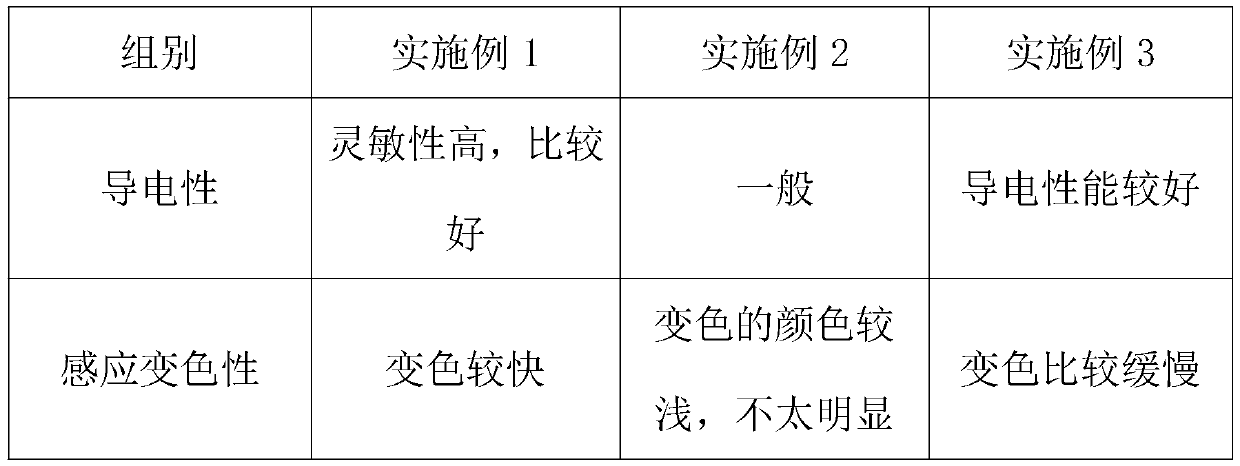

Intelligent textile new material machining method

InactiveCN111155327AGuaranteed smoothAvoid strippingDry-cleaning apparatus for textilesDyeing processYarnFiber

The invention discloses an intelligent textile new material machining method. The intelligent textile new material machining method particularly comprises the following step of: S1, adopting a raw material, i.e., 12s-30s yarns or plied yarns, which is formed by blending pure cotton or cotton and chemical fibers, wherein for 80 to 550g of a fabric per square meter, the yarns are required to have noimpurities and foreign matter and have no oil stain and moisture deterioration, silver-plated or tin-plated red copper conductive wires have a diameter of 0.10 to 0.75mm and tensile strength of 300 to 1,400N / mm<2>, wire distribution in the radial direction of the fabric is 8 to 500 pieces per meter, braided wires at the edge of each electrode are tightened up so as to prevent the electrode wiresfrom being separated from the edges, an interval of 1 to 2cm is kept between the electrodes, and electrode connection pieces are stamped red copper silver-plated connection pieces. The invention relates to the technical field of textile material machining. According to the intelligent textile new material machining method, hydrophilic modification improves moisture absorption is improved and improves the anti-static property, cooperates with a softener to reduce friction and cooperates with graphene oxide conduction to give the anti-static property of a textile fabric, so that the possibilityof an electric shock in the dry environment can be effectively reduced; and the fabric is dyed by adopting an intelligent sensing pigment, so that after the textile fabric is polluted by a great amount of acid substances such as sweat, grease and the like, the color of the fabric can be changed.

Owner:刘家叶

Electric socket

InactiveCN104466494AAvoid confusionAvoid security issuesCouplings bases/casesFlexible lead accommodationThree-phaseEngineering

The invention discloses an electric socket. The electric socket comprises a wall and a power line, wherein a socket body is embedded in the wall and provided with at least one three-phase jack and at least one two-phase jack, and the outer side of each three-phase jack and the outer side of each two-phase jack are each provided with a circle of fluorescent layer which is embedded in the socket body. The upper end and the lower end of the socket body are each provided with a fixing piece which is integrally formed with the socket body, and the fixing pieces and the outer surface of the socket body are not coplanar. The electric socket is simple in structure and reasonable in design. Because the fluorescent layers are arranged on the socket body, a user can conveniently find the jacks in the socket body at night. Because the fixing pieces are arranged, the power line can be conveniently wound on the upper fixing pieces and the lower fixing pieces, and circuit chaos and potential safety hazards caused when the power line is randomly scattered on the ground are avoided.

Owner:合肥沪联电器设备有限公司

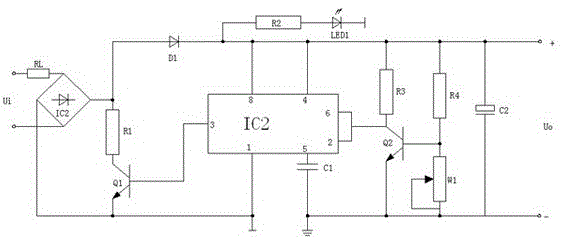

Electronic switching circuit employing capacitor filtering output and with front stage and back stage arranged isolatedly

PendingCN106100619AReal-time observation of normal operationReduce design costElectronic switchingCapacitanceElectronic switch

The invention discloses an electronic switch circuit that adopts capacitor filter output and is isolated from the front and rear stages. It is provided with an input terminal Ui, a load RL, a rectifier circuit and an electronic switch circuit. One end of the input terminal Ui passes through the connection between the load RL and the input terminal of the rectifier circuit. The first end is connected, and the other end of the input terminal Ui is connected to the second end of the input end of the rectifier circuit; the ground terminal of the input terminal of the control circuit is isolated from the ground terminal of the output filter circuit; on the output terminal of the rectifier circuit An indicator light circuit is also provided, and the resistance R1 and LED1 connected in series are arranged in the indicator light circuit, and the ground terminal of the indicator light circuit is connected with the ground terminal of the input terminal of the control circuit; the capacitor is used as the output filter circuit to reduce the design and While applying cost, it has a good filtering effect. It is equipped with an indicator circuit to observe in real time whether the working status of the circuit after the AC rectification output is normal, and to form a detection node for the inspection of the front and rear stages.

Owner:成都立威讯科技有限公司

Three-pin power supply protection seat for a high-speed railway locomotive

ActiveCN110534954AReduce electrical conductivityNo electric shockVehicle connectorsCouplings bases/casesElectricityForeign matter

The invention discloses a three-pin power supply protection seat for a high-speed railway locomotive. The protection seat comprises a base, a cover plate arranged on the base, three jacks formed on the cover plate, a plug core which is arranged on the base and can be electrically connected with a three-pin plug after the three-pin plug is inserted into the three-pin jack, a first protection assembly used for preventing foreign matters from entering the three jacks, a second protection assembly used for preventing a plugging core and the foreign matter from forming a conduction circuit after the foreign matter is inserted into a single hole or double holes in the three jacks, a third protection assembly used for preventing the plugging core and the foreign matter from forming a conduction circuit after the foreign matter is inserted into the three jacks in the three jacks. The protection seat is advantaged in that three groups of protection assemblies are adopted for joint protection, the possibility of electric shock caused by entry of the foreign matter into the jacks is reduced, safety is high, moreover, plugging of the plug is not excessively affected, and plugging is simple, convenient and labor-saving.

Owner:王嘉炜

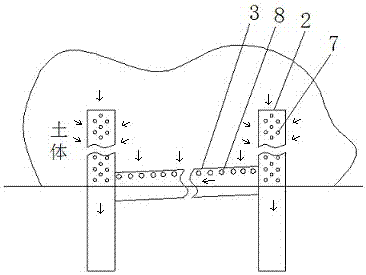

A waterproof and drainage system used in the initial support construction stage of the tunnel

The invention relates to the technical field of tunnel construction, in particular to a waterproof and drainage system used in the construction phase of the initial support of the tunnel. It includes a roof waterproof and drainage system and a straight wall waterproof and drainage system. The roof waterproof and drainage system is mainly composed of roof water diversion pipes that are driven vertically into the soil at the top of the tunnel. The straight wall water diversion pipes on both sides of the soil body are composed. The roof water diversion pipe and the straight wall water diversion pipe are provided with overflow holes in the part driven into the soil body. sump. The invention solves the drainage problem of the water-rich tunnel in the stage of initial support construction, improves the engineering quality, reduces safety risks, and has significant economic benefits.

Owner:JINAN URBAN CONSTR GRP

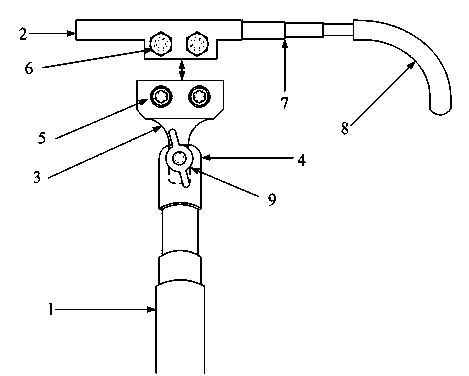

Electrical test wire clamp structure

PendingCN113985077AReduce scratchesReduce electric shockMeasurement instrument housingElectrical connectionStructural engineering

The invention discloses an electrical test wire clamp structure, and the structure comprises: a seat sleeve which is of a hollow tubular structure; a clamping part which is arranged outside the seat sleeve, wherein a pressing assembly is arranged on the clamping part; a conducting rod detachably installed in the socket sleeve and a connecting wire detachably connected to the conducting rod, wherein a connecting plug is arranged on an end of the connecting wire; a wire winding assembly used for storing the connecting wire, wherein a miniature anti-creeping switch connected to the wire winding assembly and used for detecting whether the connecting wire leaks electricity or not, the miniature anti-creeping switch is electrically connected with the connecting wire, and the conducting rod, the connecting wire, the miniature anti-creeping switch and the connecting plug form an electrical path. By implementing the electrical test wire clamp structure, the safety risks of electric shock and short circuit in the use process can be reduced; scratches of the clamping part on the surface of the electrical equipment are reduced, and the structure is simple, safe and reliable.

Owner:SHENZHEN POWER SUPPLY BUREAU

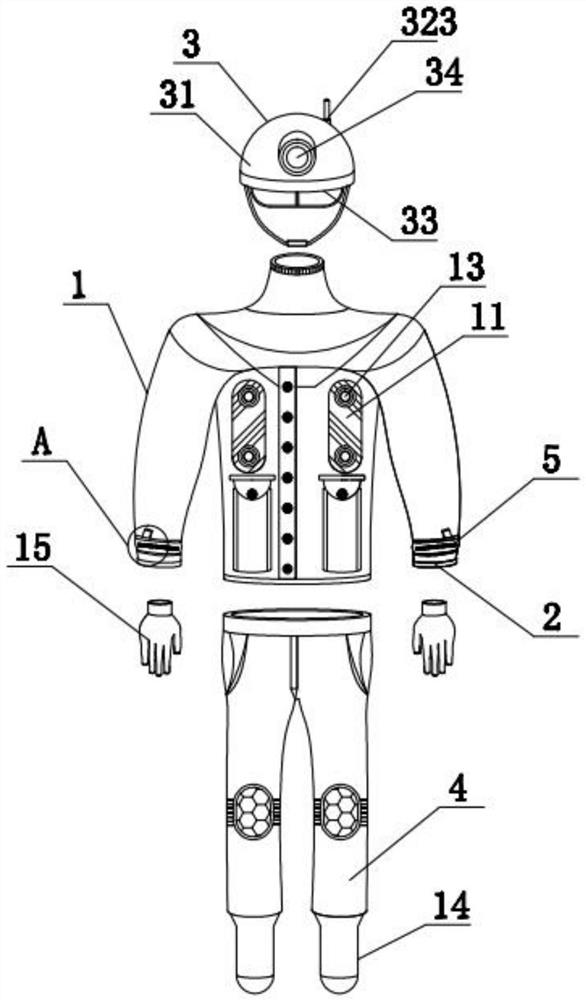

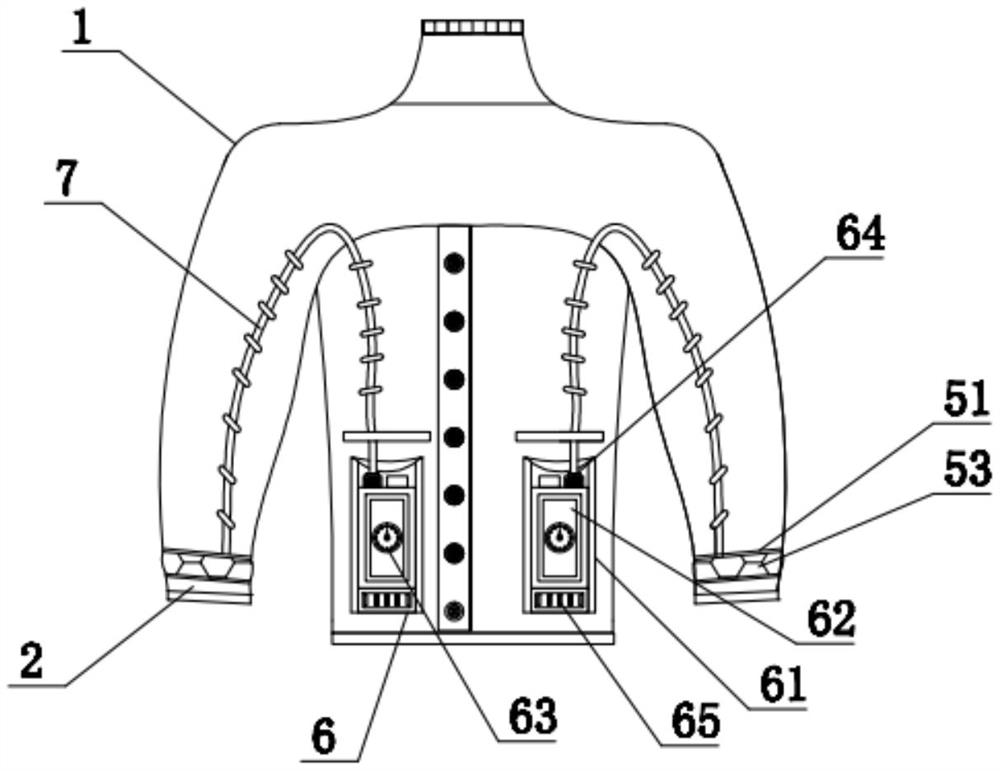

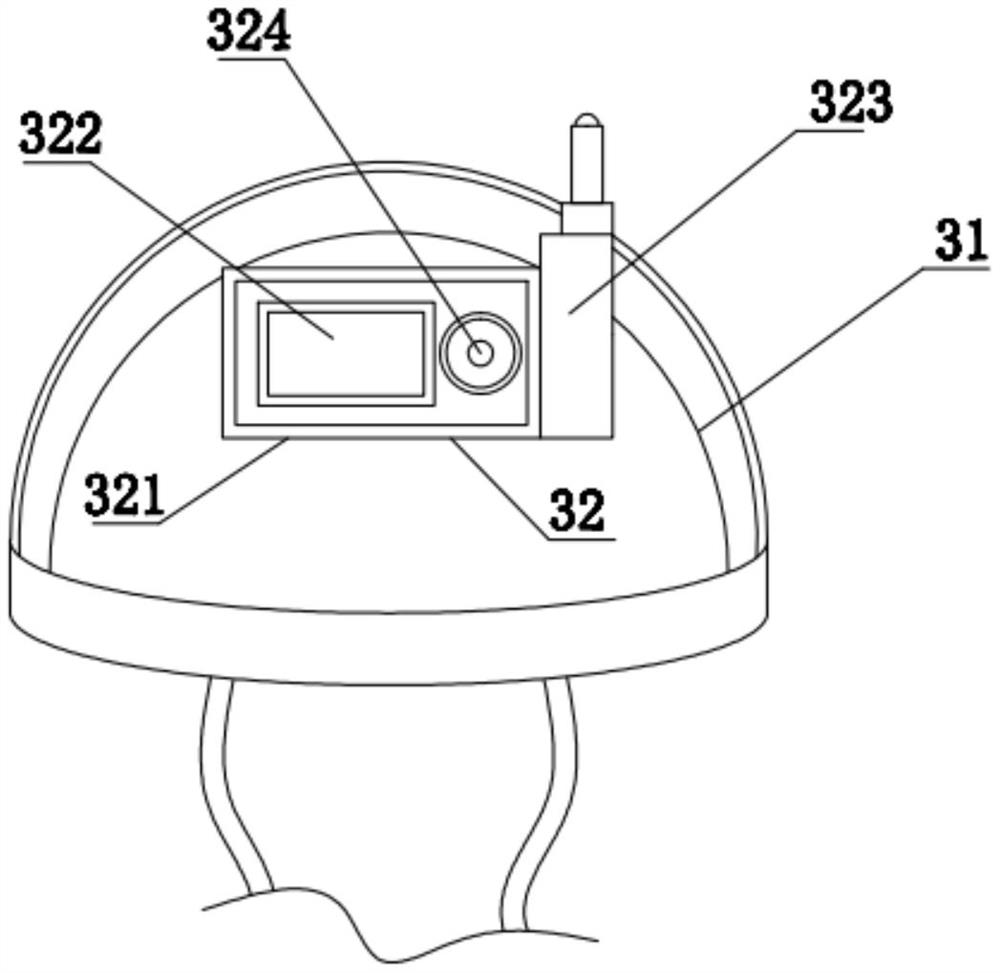

Anti-electric shock protection equipment for electrical equipment maintenance

PendingCN114223990AGuarantee the safety of lifeImprove the protective effectHelmetsHelmet coversWireless transmissionElectric power equipment

The invention discloses an electric shock protection device for electrical equipment maintenance, which comprises a protective garment, cuffs are arranged at the lower ends of the two sides of the protective garment, protective trousers are arranged at the bottom of the protective garment, a protective helmet is arranged at the top of the protective garment, and protective mechanisms are arranged at the cuffs of the two sides of the protective garment. Air supply mechanisms are arranged on the two sides of the interior of the protective clothing; a protection mechanism and an air supply mechanism are arranged and matched, so that in case that a worker gets an electric shock accidentally, a detection module in a cuff detects current, and after voltage reaches power which can injure a human body, the air supply mechanism supplies air to an air bag, so that a top cover of the air bag is zipped up, and then the hand of the worker is elastically connected with the power connection part; at the moment, through cooperation of a GPS positioning module and a wireless transmission module in the control mechanism, rescue workers are notified to go to rescue in time, the protection capacity of the equipment is effectively improved, and the life safety of the workers is guaranteed.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

An automatic air pressure drop drainage pot device for foundation pit and its use method

ActiveCN109811777BAvoid safety issues caused by breakageEnsure electricity safetyFoundation engineeringAir compressorGas holder

The invention discloses an automatic air pressure drainage kettle device for a foundation pit. The automatic air pressure drainage kettle device comprises an air compressor, an air storage tank, an air pressure control device, a floating bulb stopper, an air inlet, a water outlet, an one-way drainage valve, a drainage kettle, air guide pipes and a water guide pipe; wherein the air compressor, theair storage tank and the air pressure control device are successively connected in series through the air guide pipes; the air pressure control device is connected with the air inlet of the drainage kettle; a water inlet and the water outlet are formed at the upper end of the drainage kettle; the floating bulb stopper is installed in the water inlet; and the one-way drainage valve is installed atthe water outlet and connected with drainage equipment on the foundation pit ground through the water guide pipe. When the invention is in use, only the air guide pipes and the water guide pipe are available in a construction site and a foundation pit drainage well, thereby avoiding safety problems caused by an electric pump dropped into the well and on-site construction machinery incorrectly operated to break an electric wire; and the mutual cooperation between the air pressure control device with automatic adjustment function and the drainage kettle is utilized for realizing the efficient management to the construction site, thereby solving the technical problem.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com