Safety mechanism

A safety mechanism and technology on the other side, applied in the direction of electrical components, coupling devices, circuits, etc., can solve problems such as poor anti-unipolar plug insertion effect and unsmooth plug insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the wall switch socket junction box of the present invention will be described in detail below in conjunction with the accompanying drawings:

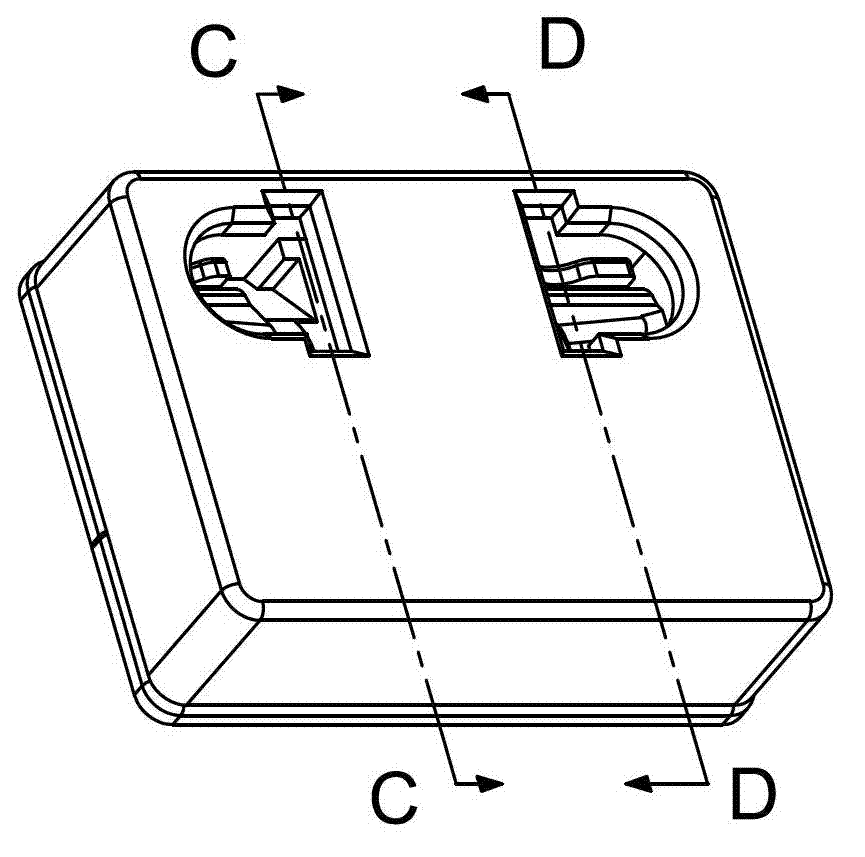

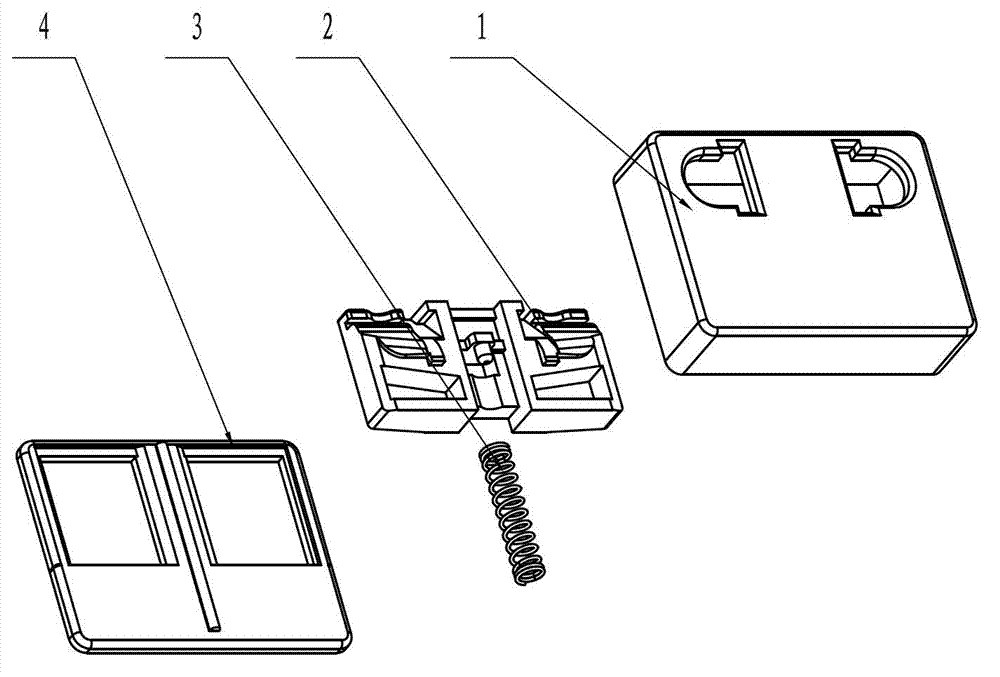

[0028] refer to Figure 1 to Figure 5 , a safety mechanism of the present invention, which includes a cover plate 1, a protective door 2 installed in the cover plate 1, a return spring 3 that provides power for the reset of the protective door 2, and a bottom plate 4 installed under the cover plate 1.

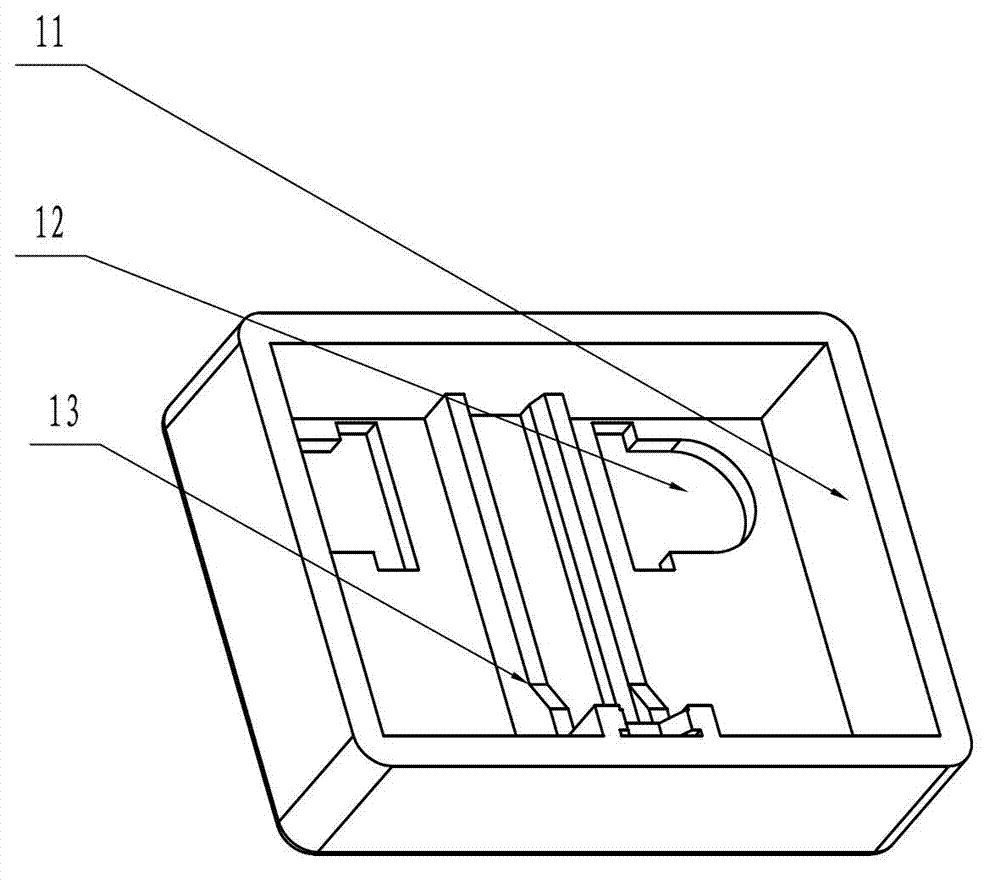

[0029] In this embodiment, the cover plate 1 has side plates 11 around it; two pin holes 12 are also provided, and two parallel ribs 13 are arranged between the two pin holes 12 .

[0030] In this embodiment, there is a boss 41 in the middle of the bottom plate 4, which is rounded; and a through hole 42 is left at the conductive part.

[0031] In this embodiment, the two sides of the front of the protective door 2 are provided with a second slope 204 and a first surface 203; There is an arc-shaped groove 207 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com