Oil and gas pipeline defect internal detector battery pack unit

An internal detector, oil and gas pipeline technology, applied in electrical components, battery pack components, circuits, etc., can solve the problems of anti-vibration design structure that does not include reliable connection of battery packs, inability to use pipeline defect internal detectors, etc. Simple structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

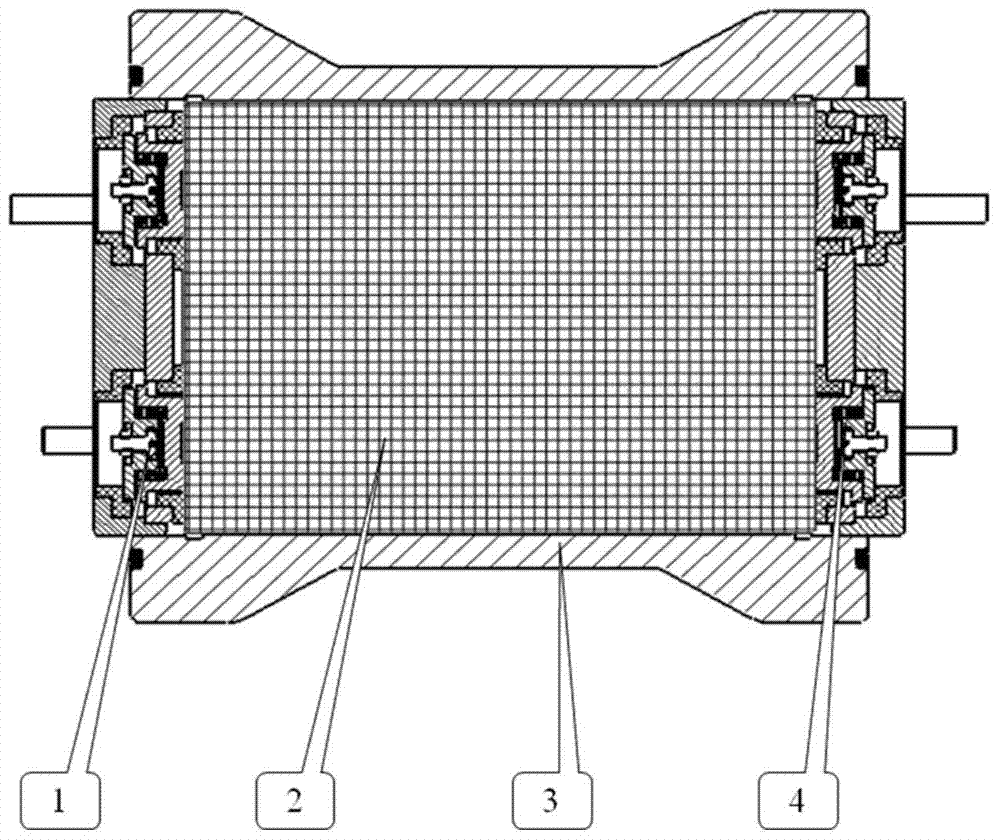

[0015] refer to figure 1 , the oil and gas pipeline defect internal detector battery pack unit, including the front electrode plate assembly 1, the high-energy lithium battery 2, the battery barrel 3 and the rear electrode plate assembly 4, the front electrode plate assembly 1, the rear electrode plate assembly 4 and the high-energy lithium battery 2 are connected After that, it is installed in the battery case 3 .

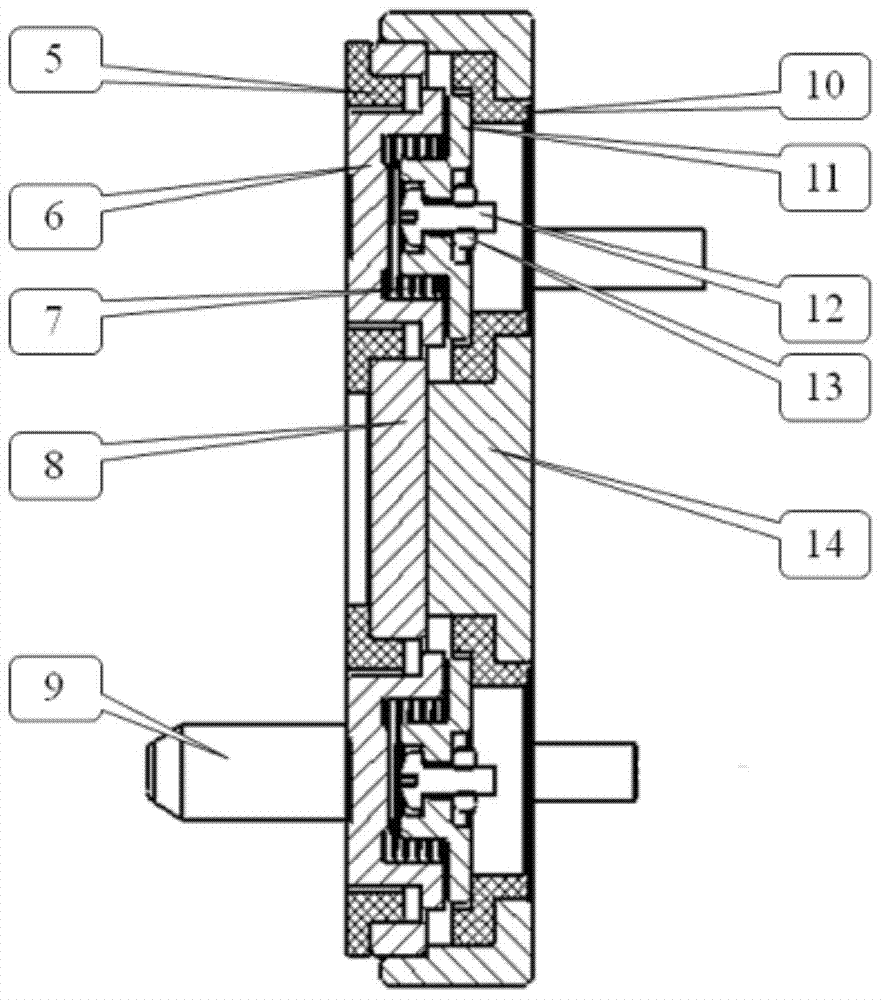

[0016] refer to figure 2 , the structure of the front electrode plate assembly 1 and the rear electrode plate assembly 4 is the same, specifically including the electrode insulating seat 5, the electrode insulating seat 5 is screwed in the fine thread thread hole of the front pressure plate 8, and the terminal insulating sleeve 10 is screwed on the rear In the fine threaded hole of the seat plate 14; the terminal 11 is pressed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com