Blind plug-in power-on structure of internal defect detector in oil and gas pipeline

A technology of oil and gas pipelines and internal detectors, which is applied in the direction of circuits, electrical components, and parts of connecting devices. and other problems, to achieve the effect of reliability, impact resistance, simple structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

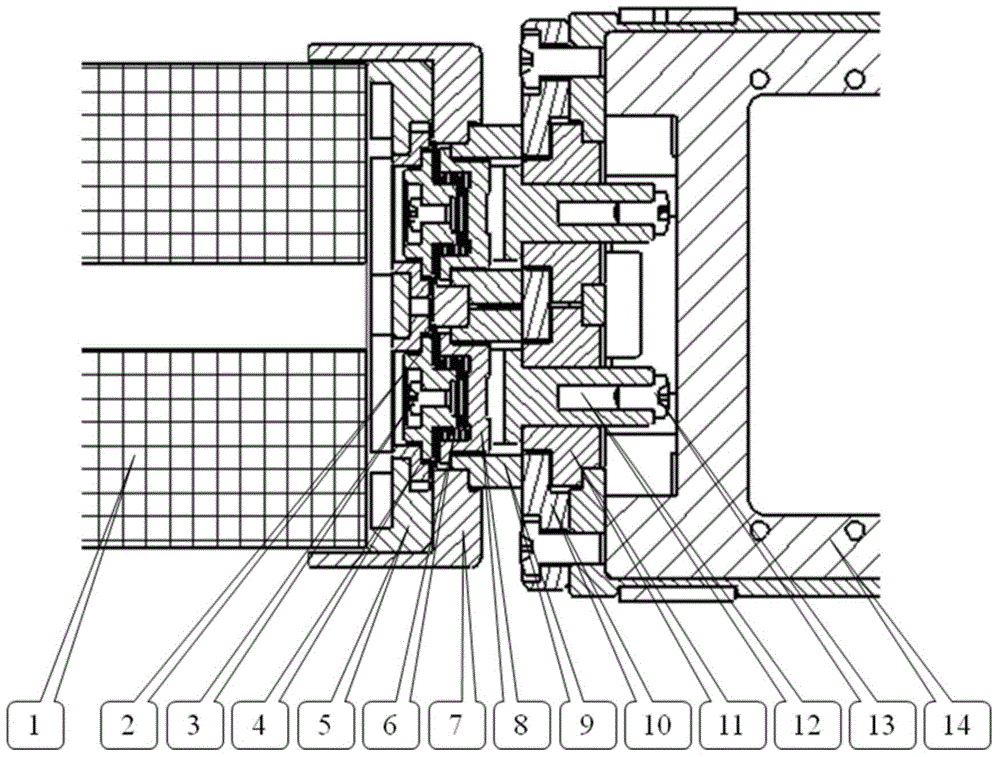

[0021] refer to figure 1 , the blind plug-in power-on structure of the oil and gas pipeline defect internal detector, including the blind plug-in power-on structural component of the battery pack unit 1 and the blind-plug power-on structural component of the electronic recorder 14, respectively installed in the battery of the oil-gas pipeline defect internal detector At the tail of the pack unit 1 and the electronic recorder 14, after blind insertion, the battery pack unit 1 can supply power to the electronic recorder 14, and the electrodes and terminals of the two parts of the blind plug-in structure are installed with polyoxymethylene plastic as an insulating sleeve to prevent battery damage. The leakage of the power supply of the package unit 1 and the electronic recorder 14 is short-circuited.

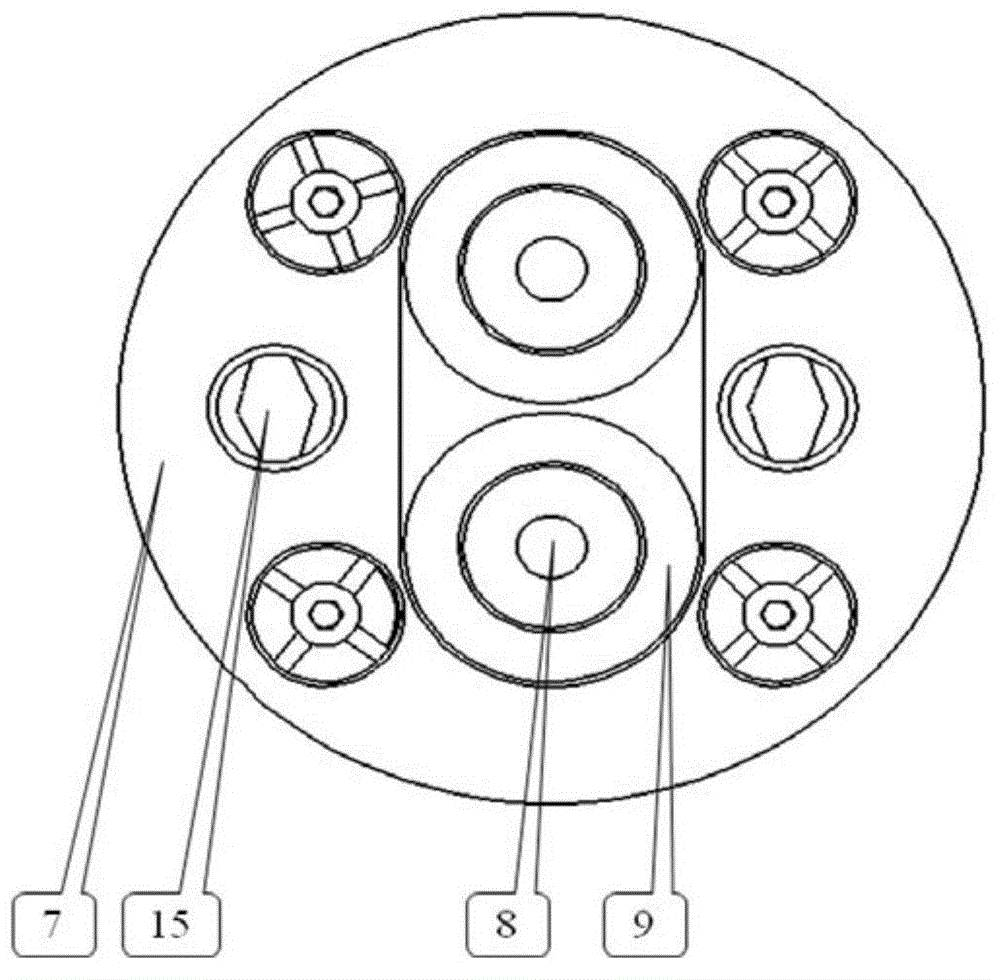

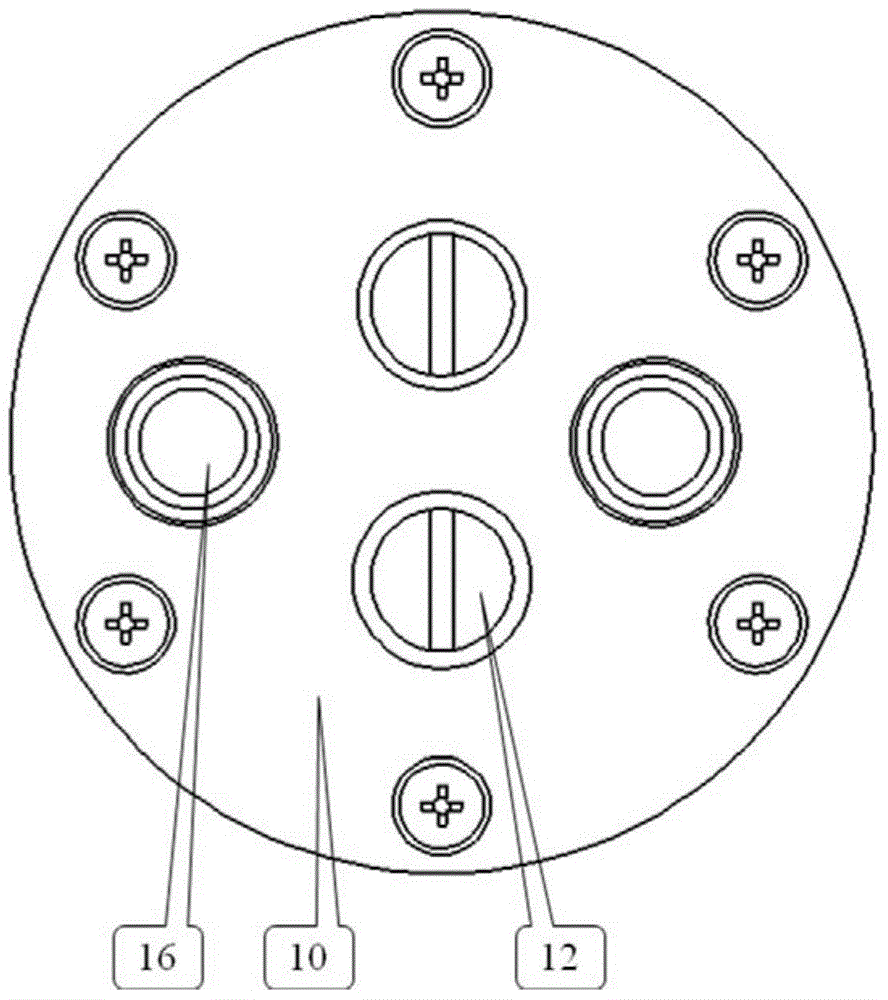

[0022] refer to figure 2 , the blind plug-in elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com