Manufacturing method of surface adhered light-emitting element lamp group

A surface-adhesive, light-emitting element technology is applied in the field of process design of semiconductor light-emitting element lamp sets to achieve the effects of saving man-hours, precise positioning, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments adopted by the present invention will be further described through the following embodiments and accompanying drawings.

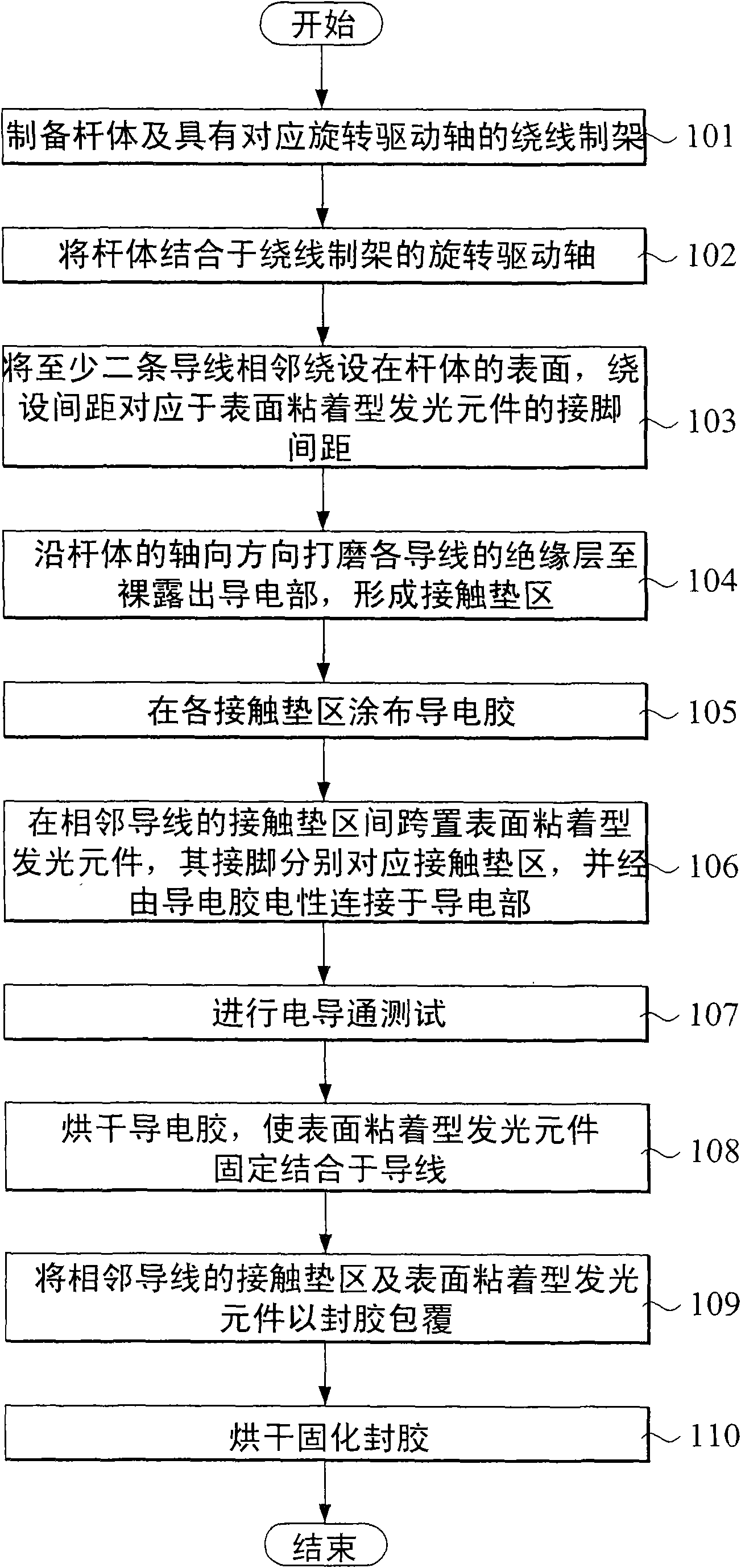

[0053] refer to figure 1 As shown, it is a flow chart showing the steps of the preferred embodiment of the present invention, and at the same time coordinates Figure 2 to Figure 12 A description of the preferred embodiments of the present invention is as follows.

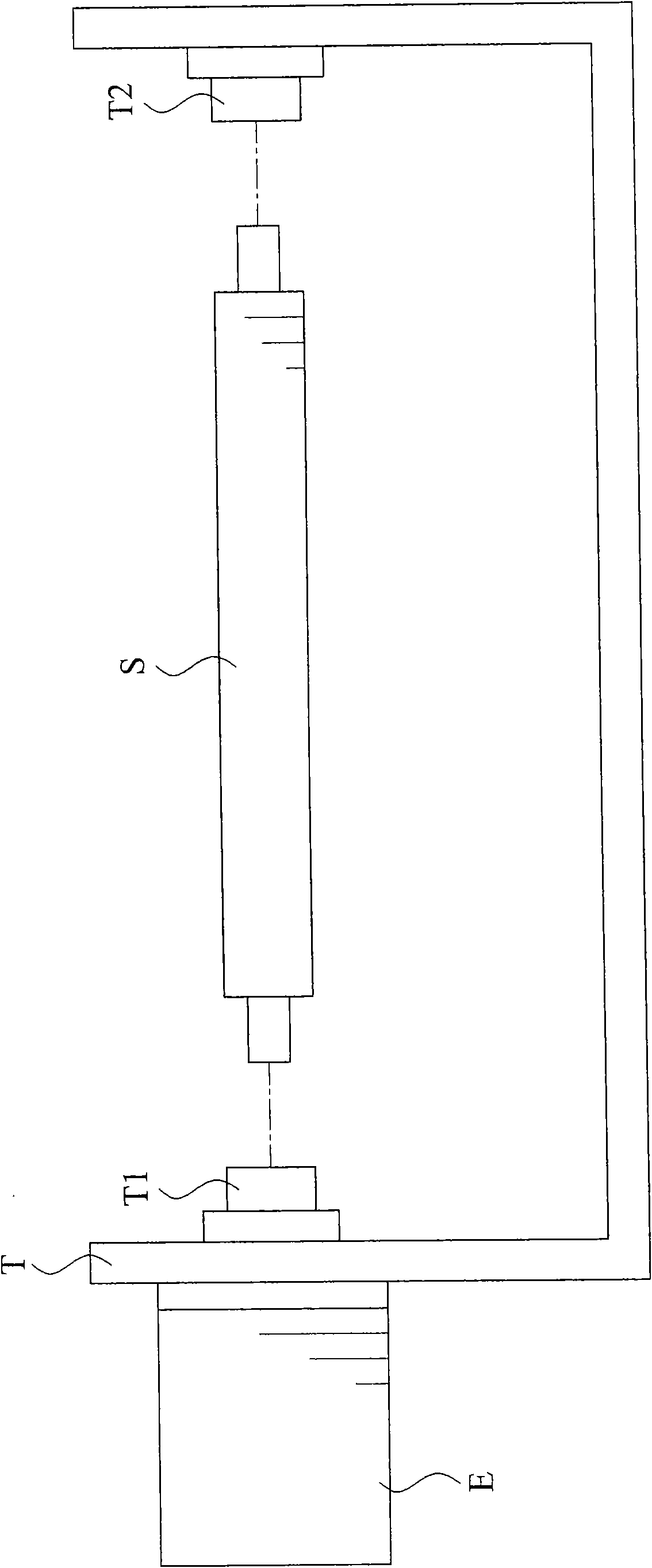

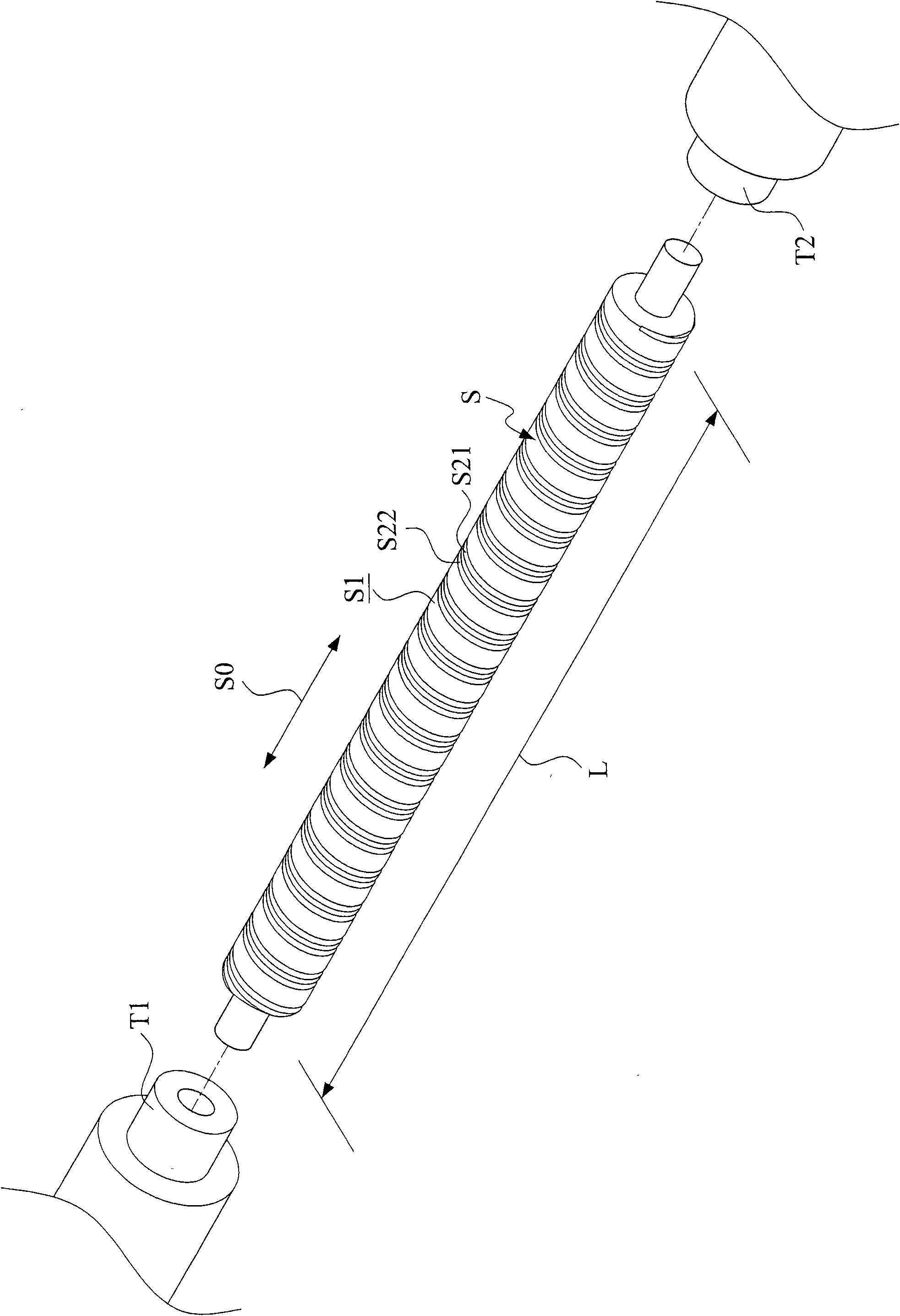

[0054] refer to figure 2 , image 3 and Figure 4 , first prepare a rod S with a predetermined length L and a winding frame T with corresponding rotating drive shafts T1, T2 (step 101). Then the rod S is combined with the rotating drive shafts T1 and T2 of the winding frame T, and the rotating driving shafts T1 and T2 are driven to rotate by a winding device E (step 102 ).

[0055] refer to Figure 5 When at least two wires 1, 2 with outer covering insulating layers 11, 21 are arranged at a predetermined winding distance D, when the rod body S is driven to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com