High-moisture-resistance metallized polypropylene film capacitor and processing method thereof

A polypropylene film, high moisture resistance technology, used in film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc. Improved humidity resistance and reduced capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

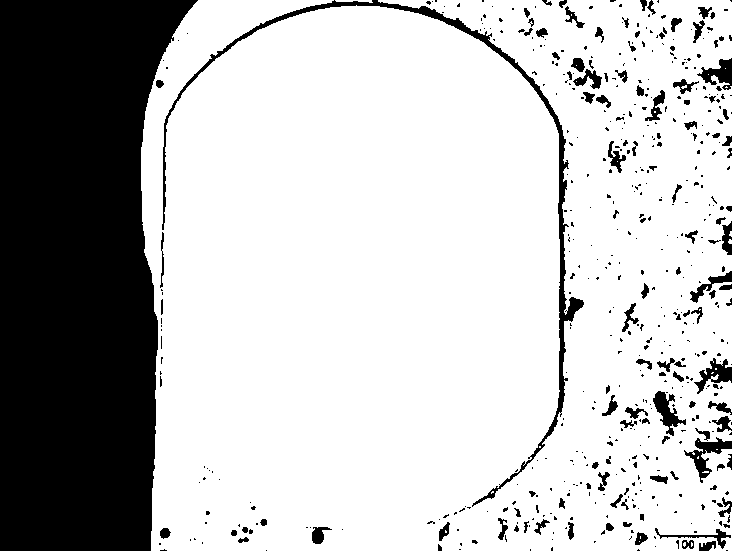

[0027] see Figure 1~2 , in the embodiment of the present invention, a kind of processing method of metallized polypropylene film capacitor with high moisture resistance comprises the following steps:

[0028] S1, coating, low-temperature plasma corona treatment on the surface of the polypropylene film, so that the surface of the polypropylene film can form dangling bonds, and then a metal coating is applied on the surface of the polypropylene film, and a layer of anti-oxidation oil is coated on the outside, To protect the metallized polypropylene film, it can effectively improve the moisture resistance of the metallized polypropylene film by 30%. The German Leybold Optical High Vacuum Coating Machine, model CAP-M900, is used for coating. The main process parameters are set For vacuum degree 5*10 -4 Pa, aluminum evaporation boat temperature 1100°C, zinc furnace temperature 650~700°C, shielding oil temperature 115-120°C, protective oil temperature 140°C, main drum temperature ...

Embodiment 2

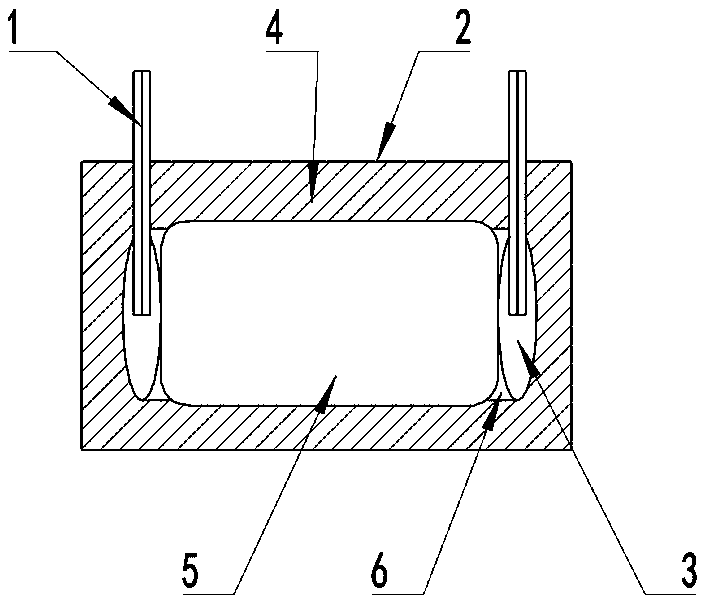

[0036] see image 3 , the embodiment of the present invention also proposes a metallized polypropylene film capacitor with high moisture resistance, comprising a wire 1 and a core 6, the surface of the core 6 is provided with a gold-sprayed layer 3, and the core 6 is covered with aluminum foil Adhesive tape 5, core 6 is encapsulated by PPS plastic shell 2, and anhydride epoxy resin 4 is potted between PPS plastic shell 2 and core 6, wire 1 is connected with core 6 and passes through PPS plastic shell 2 Compared with the existing amine epoxy resin, it is denser and thus has better moisture resistance. As mentioned in the above embodiment, the aluminum foil tape 5 can resist external moisture for the core 6, and the PPS plastic shell 2 The combination with moisture is small, so it can play a better moisture-proof effect.

[0037] After obtaining the finished metallized polypropylene film capacitor, it is subjected to a double 85 test, and the test results Figure 4 shown. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com