Adjustable pin distance large-size locating device with two pins on one side

A positioning device and adjustable technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as affecting the normal operation of mechanical devices, damage to mechanical devices, and difficulty in ensuring the parallelism of two holes and the perpendicularity of holes and surfaces. , to achieve the effect of meeting work requirements, high strength, and solving positioning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

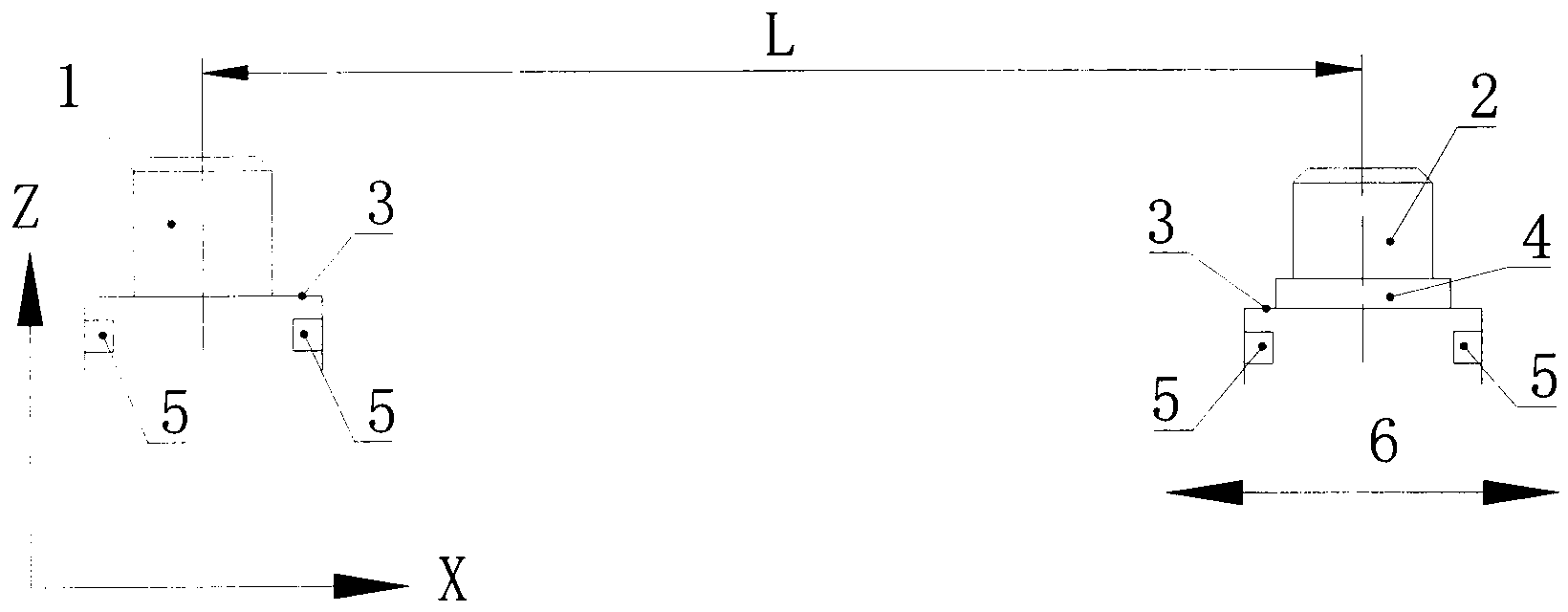

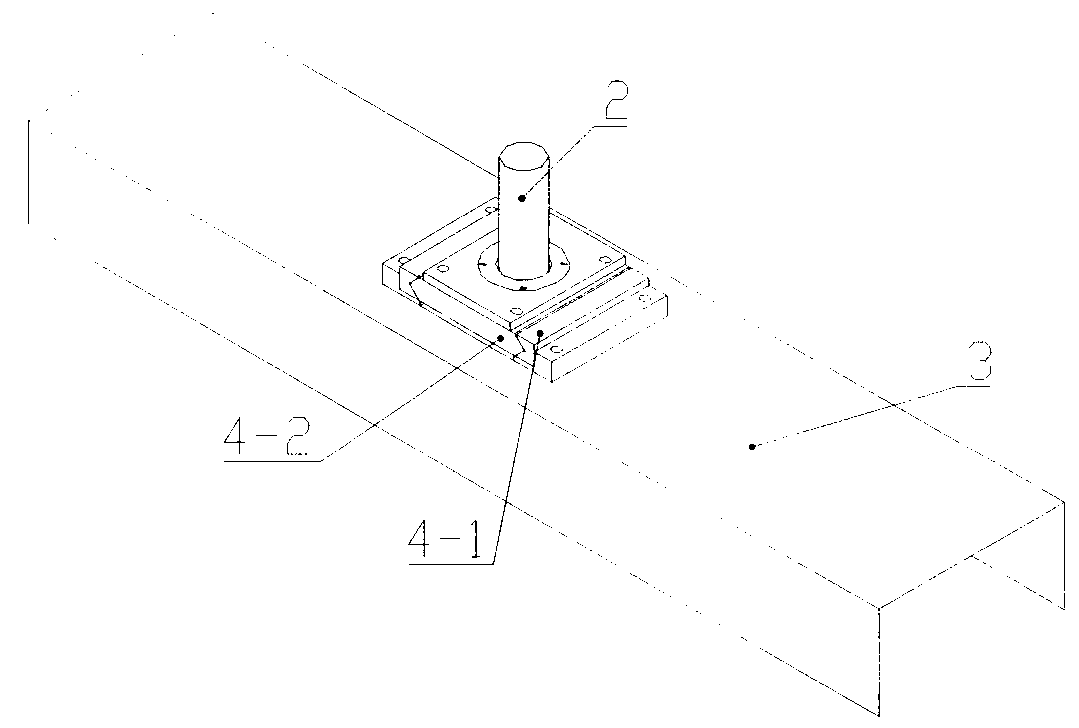

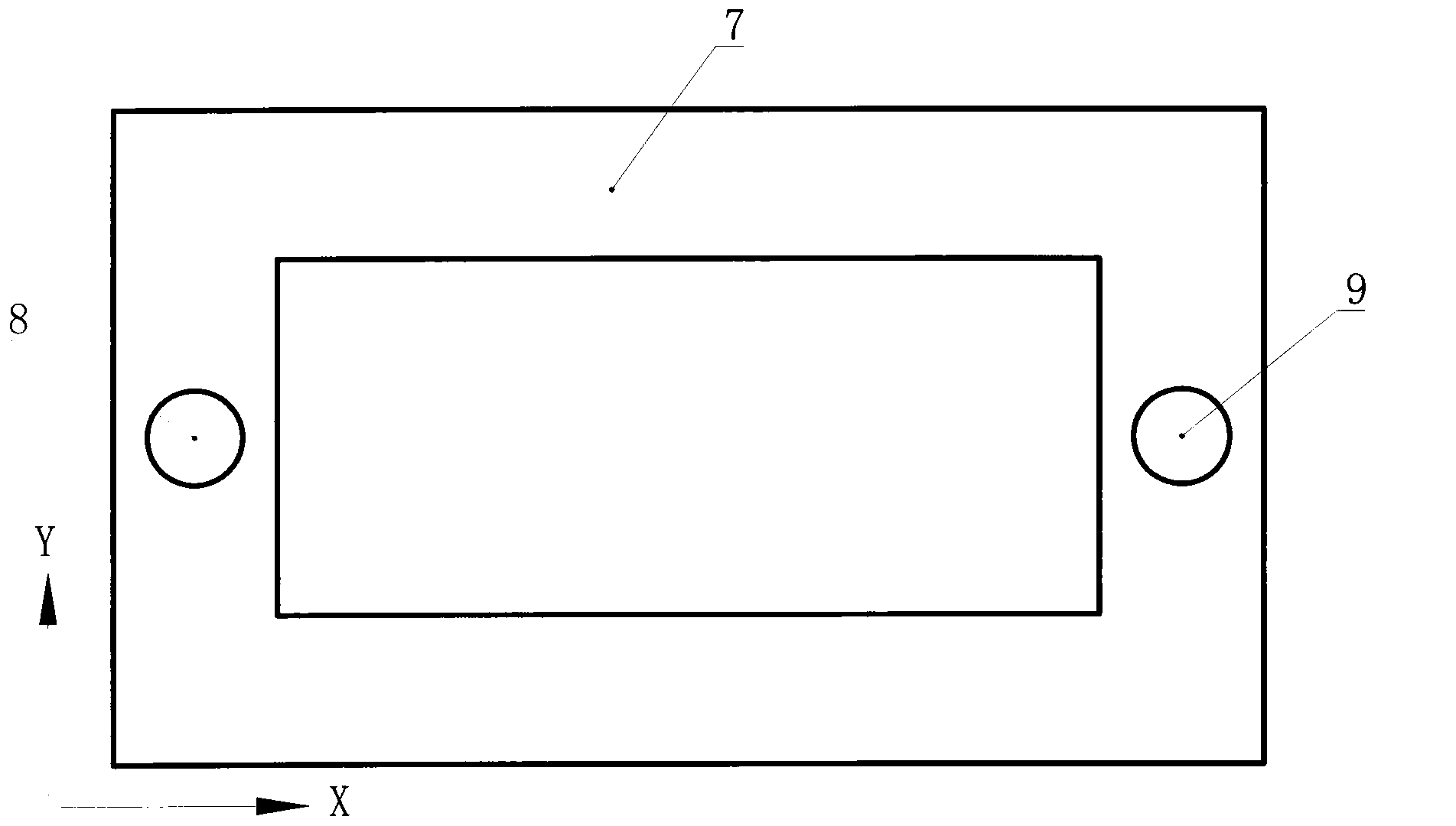

[0014] Such as Figure 1-Figure 2 As shown, the large-scale positioning device of the present invention is made up of fixed positioning pin 1, movable positioning pin 2, positioning block 3, moving pair 4, at least eight guide wheels 5, the positioning surfaces of left and right positioning blocks 3 are equal, and positioning block 3 At least two guide wheels 5 are fixedly connected to each side of the side plate, and the large-scale positioning device is installed in the guide groove of the large-scale mechanical guide rail through at least eight guide wheels 5, and the required movement is realized with the transmission mechanism; the fixed positioning pin 1 is floatingly installed in the positioning On the positioning surface of the block 3, the fixed part 4-1 of the moving pair 4 is fixedly connected with the positioning surface of the positioning block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com