A detection module and its installation method

A detection module and detector technology, applied in the field of space detectors, can solve problems such as abnormal lap resistance, large dimensional tolerance, and small pin spacing of detectors, and achieve the effect of ensuring positioning accuracy, stable connection, and ensuring pin spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

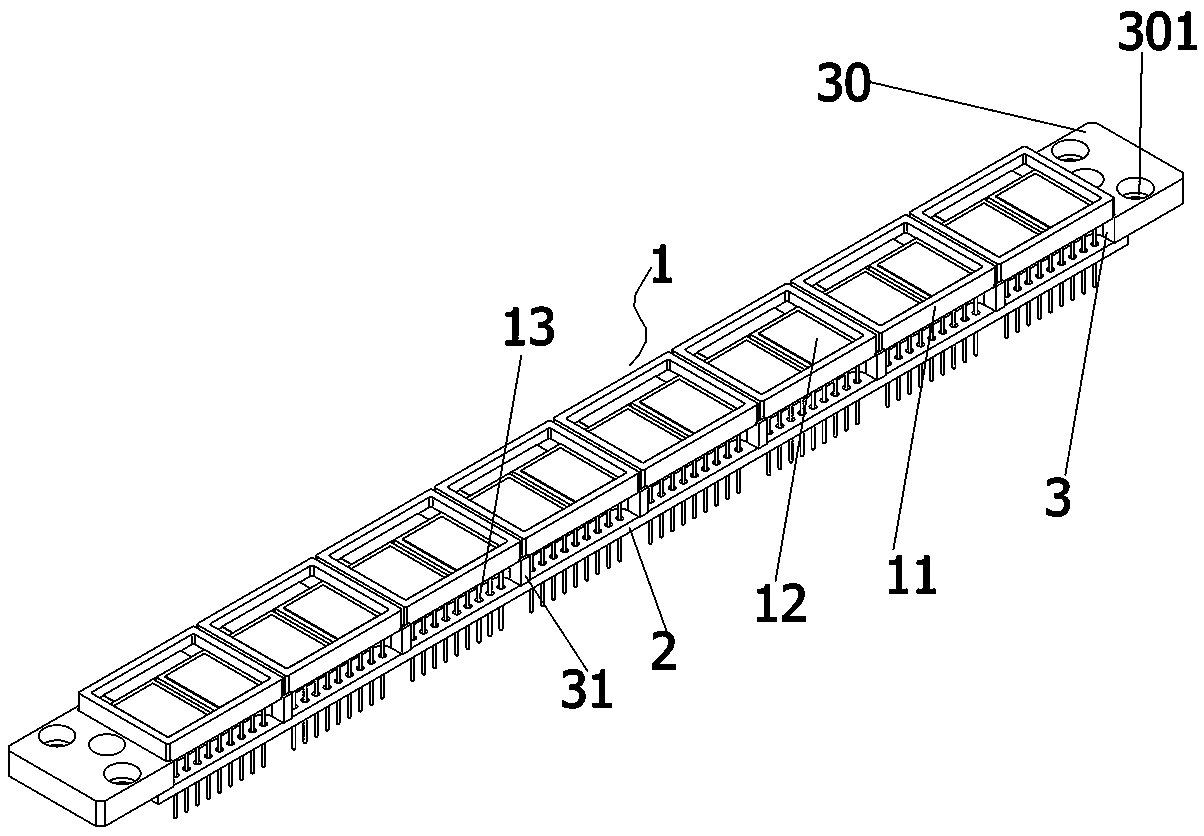

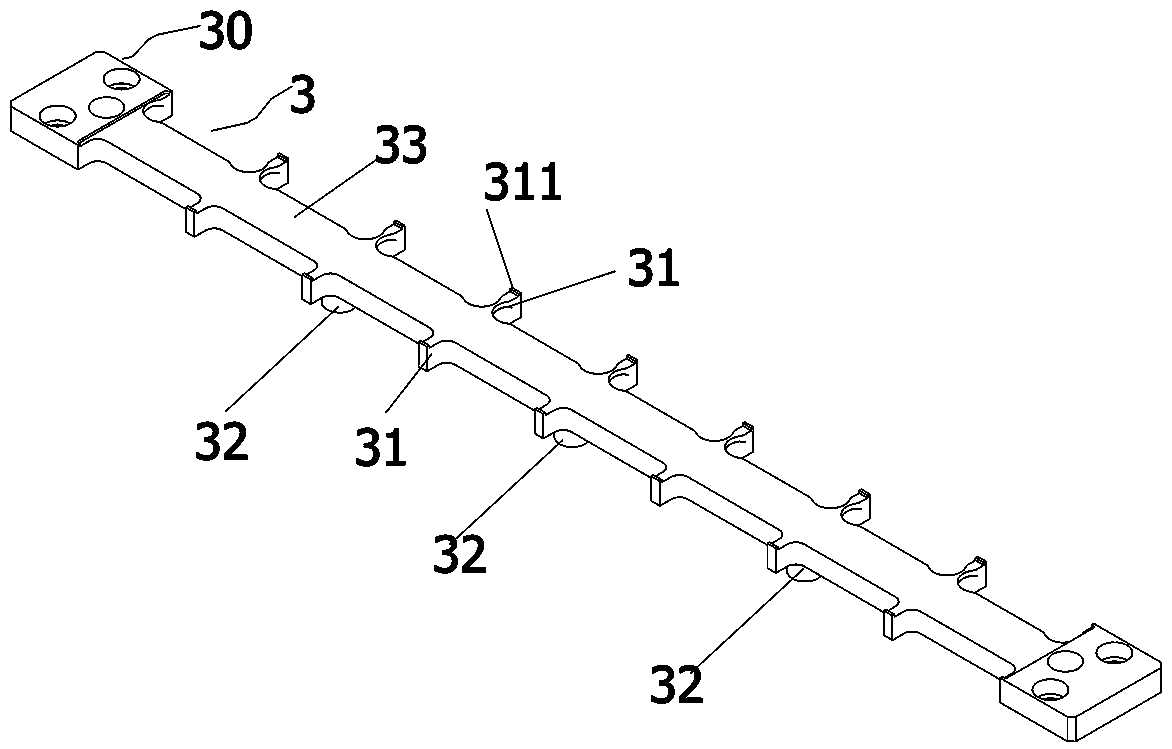

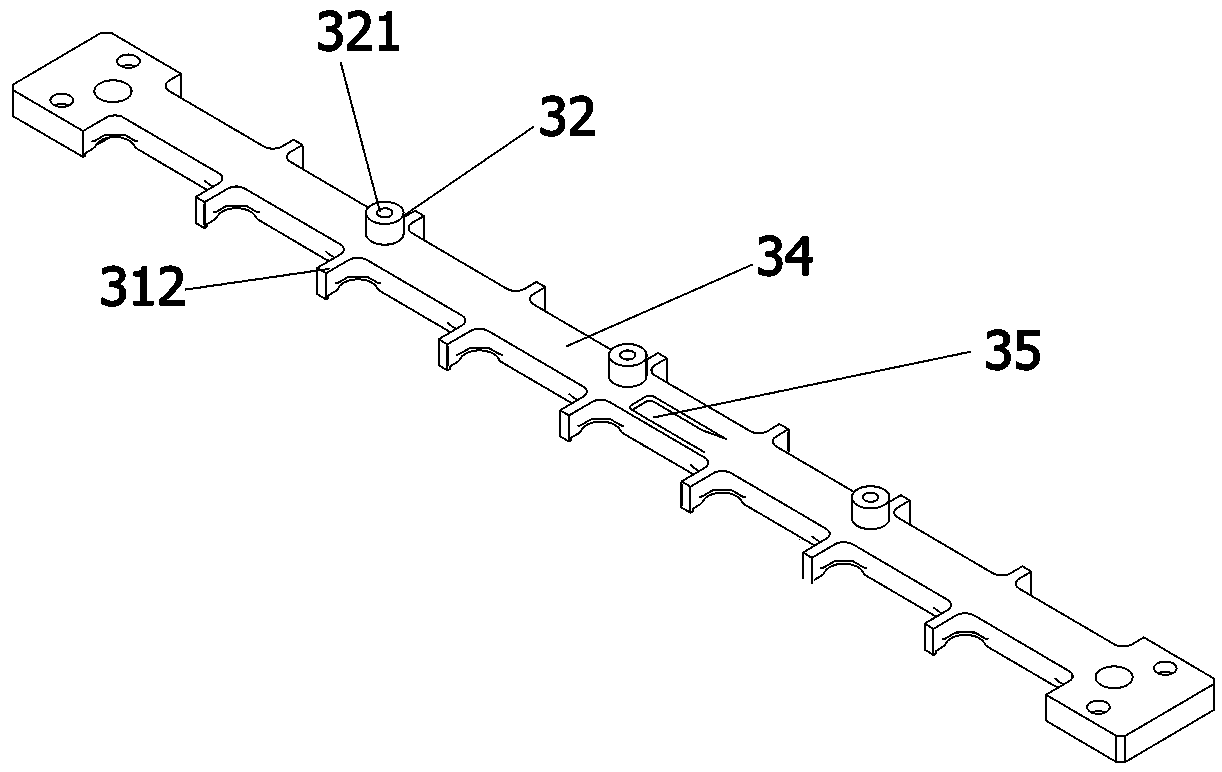

[0024] see Figure 1-4 As shown, a detection module includes a detector 1 and a detector welding PCB 2, and the detector and the detector welding PCB are installed and fixed on two surfaces of a strip-shaped metal plug-in board 3 respectively, and the metal plug-in board 3 On both sides of the length direction of the connecting plate, there are multiple groups of relative outward horizontally protruding ribs 31, and the ribs on each side are arranged at the same distance. The detector of the metal plug-in board 3 is welded to the connecting side 34 of the PCB. A plurality of positioning bosses 32 are formed on the top, and a threaded hole 321 is formed in the center of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com