Paving method for sintering machine's bilayer bedding materials

A technology for laying bottom material and sintering machine, which is applied in the field of iron ore sintering, can solve the problems of reducing the weight of blast furnace sinter, reducing the high-quality particle size of finished ore, and increasing the process cost, and achieves the effect of reducing the amount of material used for large-sized sinter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The sintered ore is produced by double-layer bottom material method.

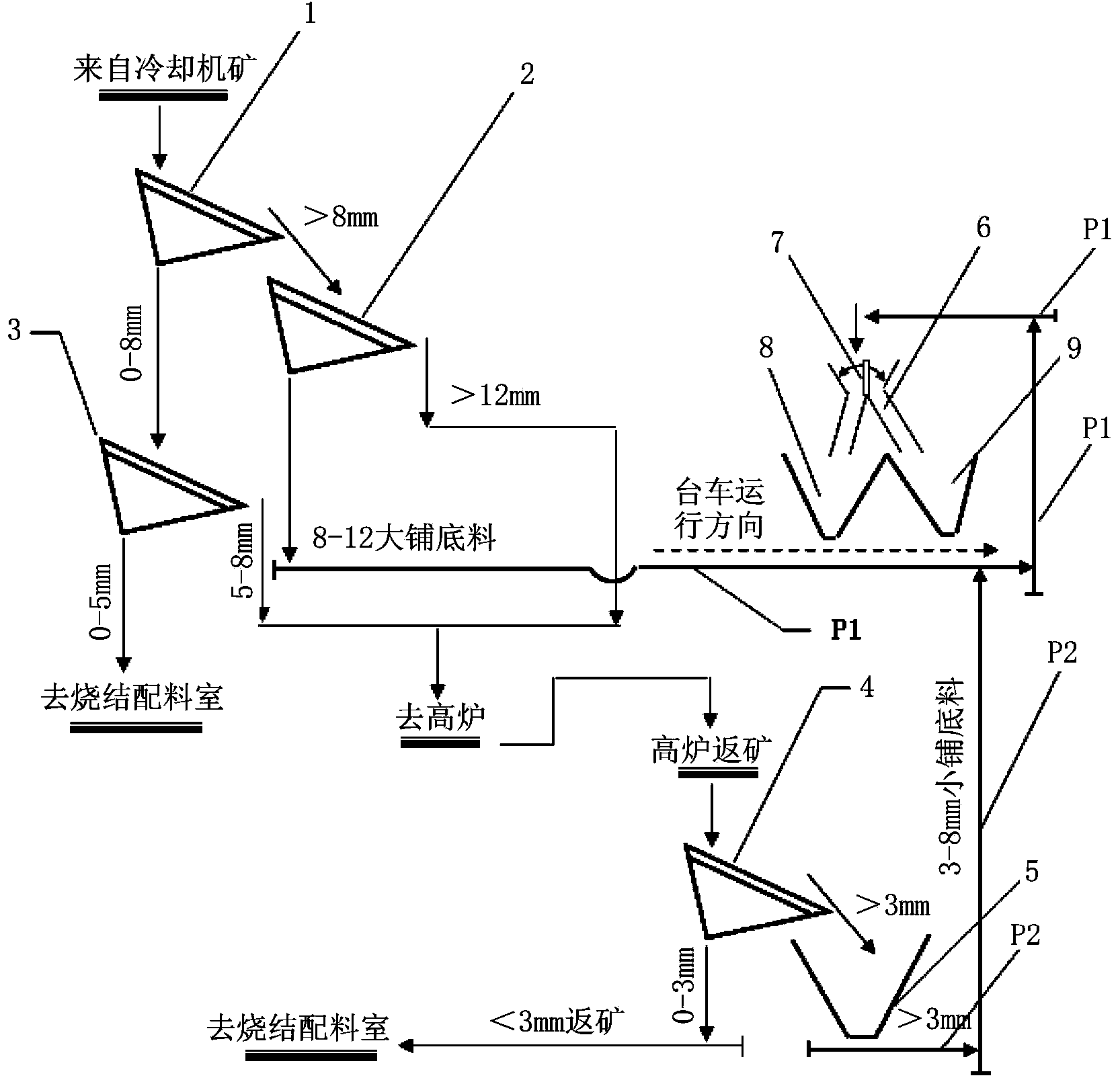

[0043] The sintered ore coming out of the blast ring cooler is sent to the primary cooling vibrating screen 1 in the screening room for the first screening. The sieve classification point of the primary cooling vibrating screen 1 is 8mm, and the products of the particle size on the screen enter the secondary The secondary cooling vibrating screen 2 performs secondary screening, and the products under the sieve enter the tertiary cooling vibrating screen 3 in the screening chamber for three screenings; in the secondary screening, the secondary cooling vibrating screen 2 sieves The point is 12mm, and the products of the size below the sieve are sent to the bottom material silo 8 through the bottom material conveying belt P1 as the bottom material of the bottom sieve. The raw materials are transported to the blast furnace; in the third screening, the grading point of the third sieve of the third cold or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com