Household garbage and burning fly ash joint-disposal method and equipment

A technology for incinerating fly ash and domestic waste, which is applied in the direction of combustion methods, lighting and heating equipment, incinerators, etc., which can solve the problems of high selectivity requirements for furnace materials, unobvious economic benefits, and high processing costs, and achieve obvious economic benefits , Exhaust gas treatment system simplification, less maintenance cost and less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

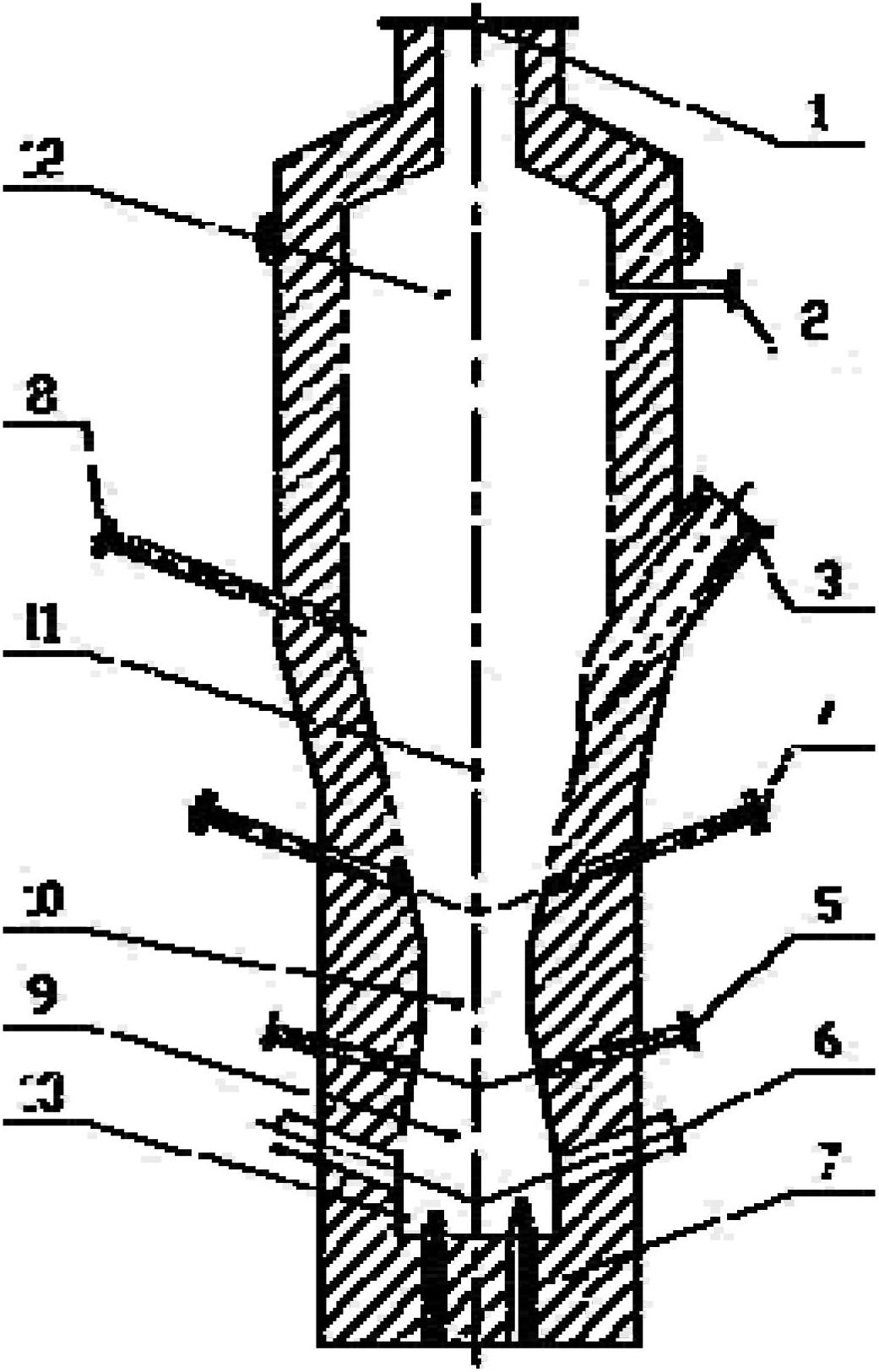

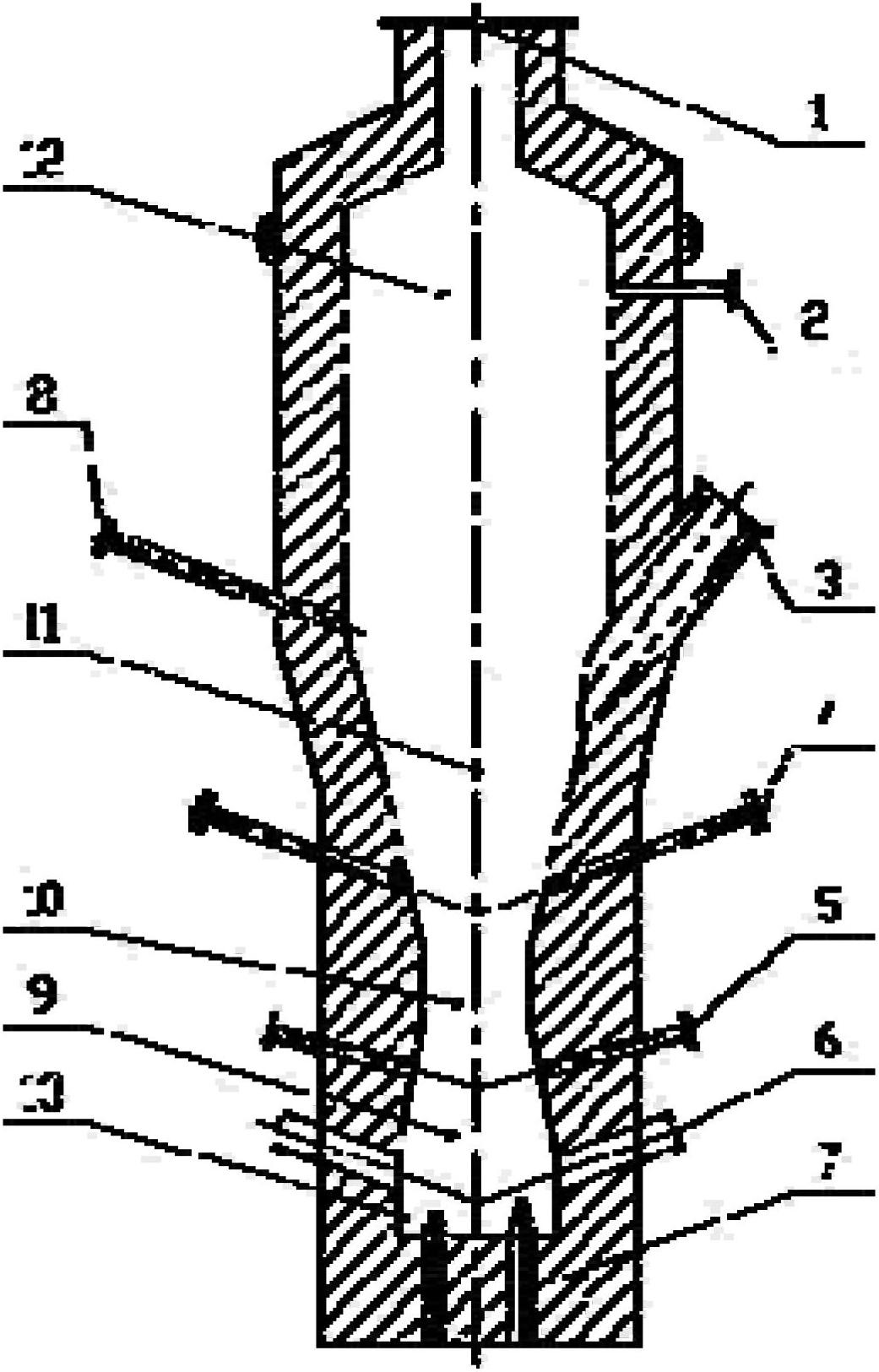

[0027] see figure 1 As shown in the present invention, a domestic waste and incineration fly ash co-disposal equipment includes a plasma torch system and a gasification melting furnace.

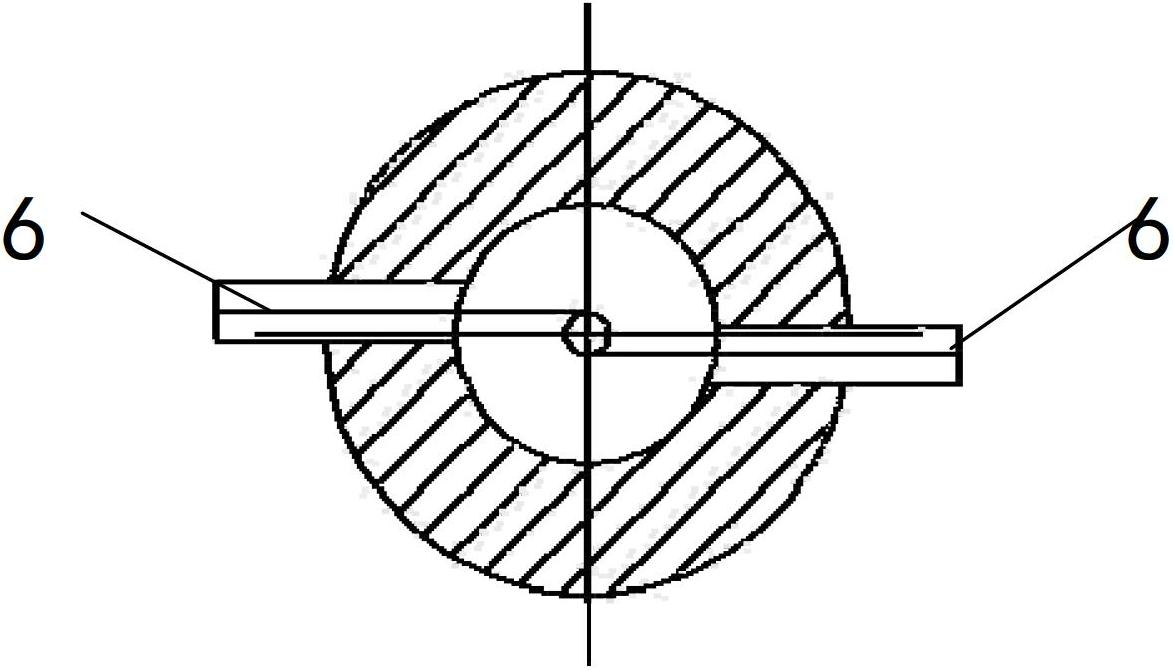

[0028] The gasification melting furnace of the present invention adopts an updraft design, and a slag outlet 7 is provided at the bottom of the furnace body, and a gas outlet 1 is provided at the top. The cavity of the melting furnace is sequentially composed of a slag bin 13, a melting combustion chamber 9, a gasification chamber 10, a drying chamber 11 and a gas negative pressure chamber 12 from bottom to top, and a feed bin 3 is connected above the drying chamber 11. On the furnace wall of the melting furnace, a plasma torch interface 6 is provided between the melting combustion chamber 9 and the slag bin 13, an air inlet is provided on the side wall of the gasification chamber 10, and a thermocouple interface 2 is provided on the side wall of the gas negative pressure chamber 12.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com