Plasma reaction system for treating hazardous wastes and working method of plasma reaction system

A plasma and hazardous waste technology, which is applied in the direction of combustion method, combustion product treatment, lighting and heating equipment, etc., can solve the problems of secondary pollution of incineration devices, large public resistance, etc., and achieve low cost and time and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

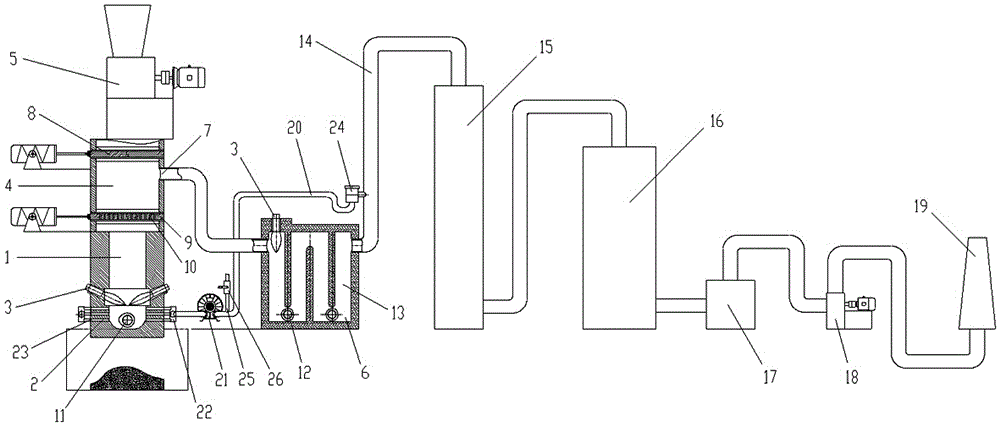

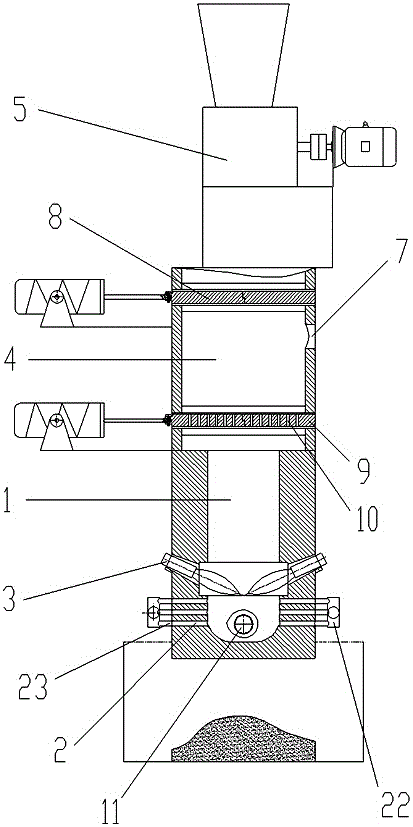

[0022] Such as Figure 1~2 As shown, a plasma reaction system for treating hazardous waste includes a gasification chamber 1, an air inlet 2 is arranged at the bottom of the gasification chamber 1, and a plasma fire cabinet 3 is arranged above the air inlet 2 in the gasification chamber 1 A pyrolysis chamber 4 is arranged above the gasification chamber 1, a four-shaft crusher 5 is arranged above the pyrolysis chamber 4, and a gas outlet 7 connected with the air inlet of the purification chamber 6 is arranged on the side of the pyrolysis chamber 4. A hopper is arranged above the shaft crusher 5, and the crushed material of the four-shaft crusher 5 falls directly into the pyrolysis chamber 4, and falls into the gasification chamber 1 after being pyrolyzed through the pyrolysis chamber 4. A highly ionized high-temperature gas up to 5000°C is produced in the gasification chamber, so that the organic matter in the crushed waste can be efficiently converted into synthesis gas (mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com