Raw coke oven gas dedusting device and raw coke oven gas dedusting method

A technology of dust removal device and waste gas, which is used in gas dust removal, gas purification of condensed non-gaseous materials, etc., can solve the problems of filter cake falling off, high temperature corrosion of electrode wires, and tar yield decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

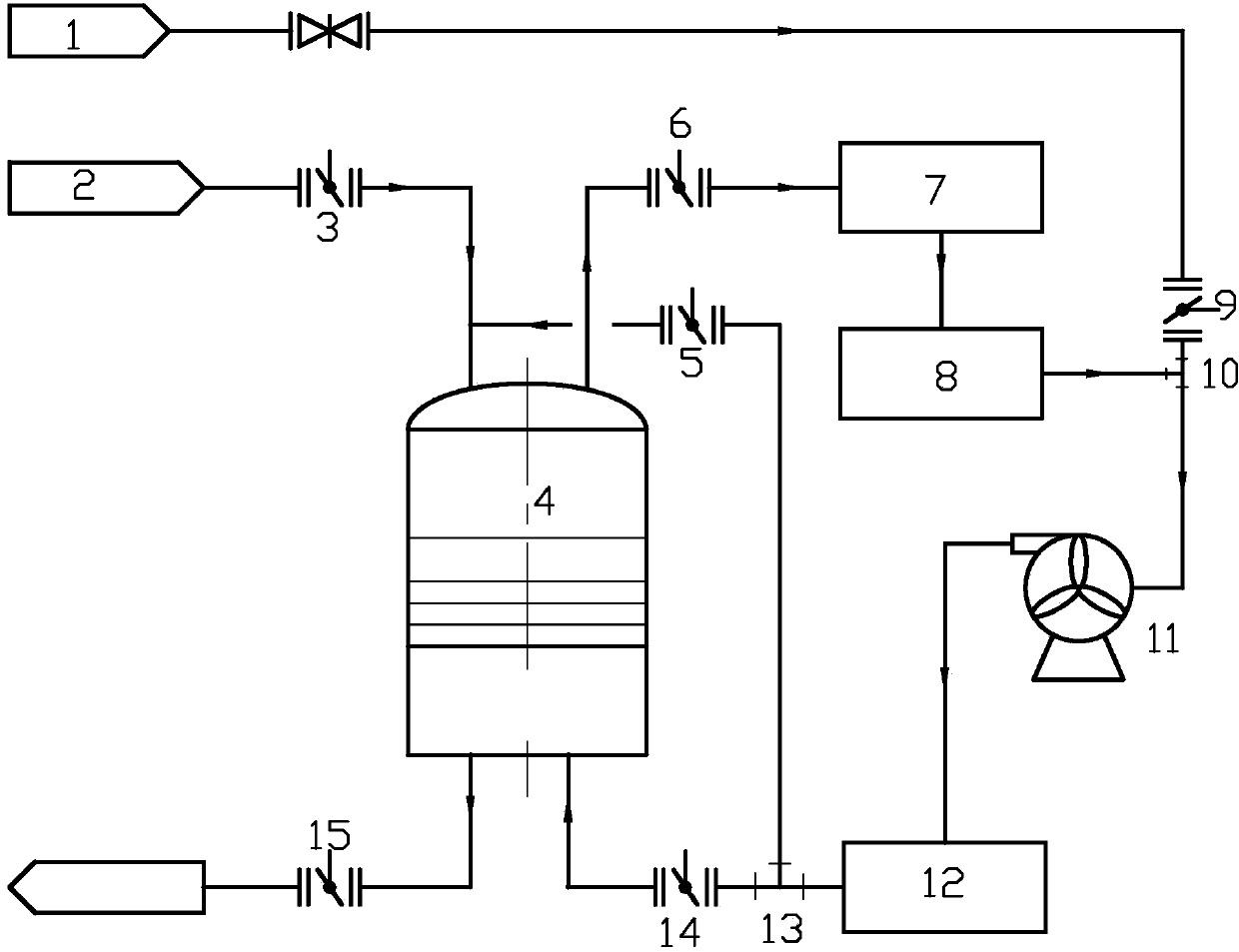

[0026] Taking dusty raw gas with a treatment temperature of 350-600°C and a pressure of 4-10KPa as an example, the dust removal device in this embodiment consists of an independent dust removal unit, see figure 1 , the dust removal unit includes replacement and back blowing gas tank 1, raw gas pipeline 2, raw gas control valve 3, filter 4, replacement gas control valve 5, back blowing gas outlet valve 6, gas cooler 7, bag filter 8 , oil-free gas control valve 9, first T-shaped valve 10, circulating fan 11, heater 12, second T-shaped valve 13, reverse blowing gas inlet valve 14 and purge gas control valve 15 are connected to form.

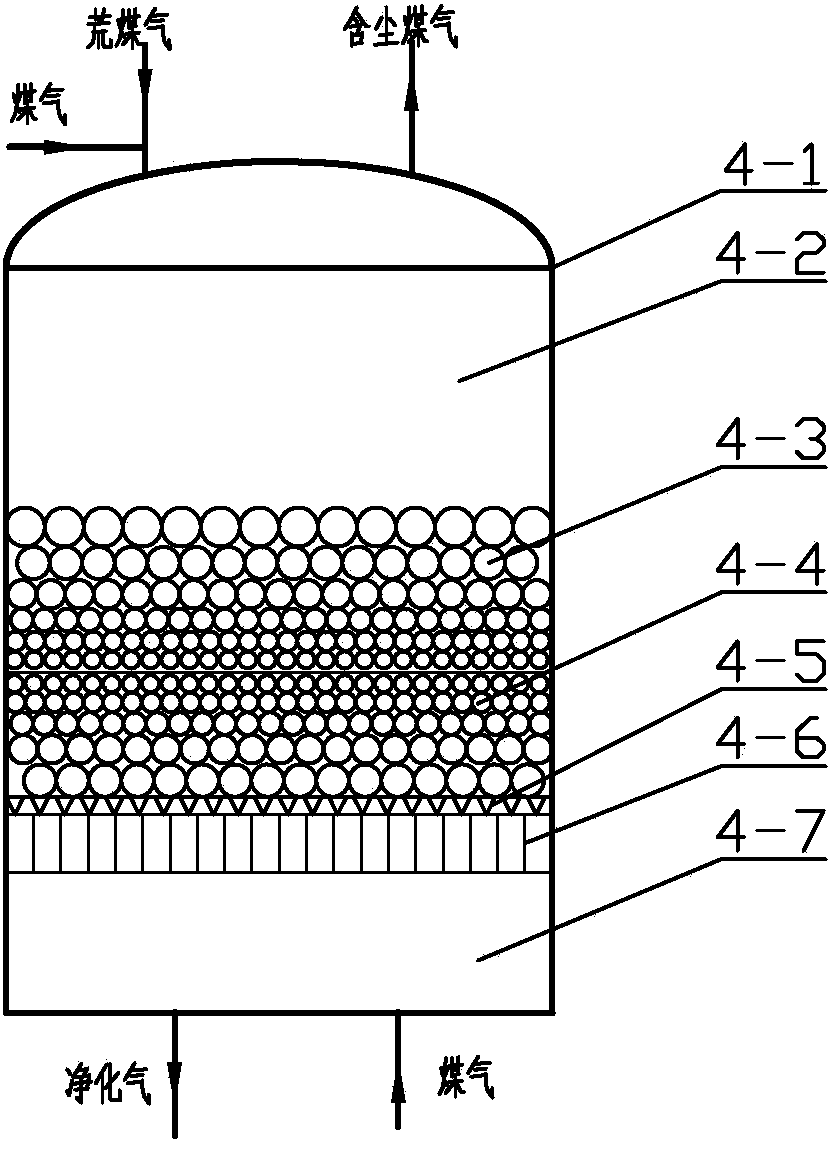

[0027] The top of the filter 4 of this embodiment is processed with an air inlet and an air outlet, and a tee is installed on the air inlet, and one port of the tee is passed into the raw gas through the raw gas pipeline 2, and the other port is connected to the replacement The replacement gas is introduced into the gas pipeline. A raw gas control v...

Embodiment 2

[0037] In this embodiment, the filter layer 4-3 uses expanded perlite as the filter material, and the thickness of the filter material is 400mm. The expanded perlite is distributed according to the size of the interlayer particles, and the particle size from top to bottom is 6-1.5mm. , the bulk density distribution is 60~800kg / m 3 . The steady flow layer 4-4 is arranged with olivine, with a thickness of 600mm. The olivine is distributed in the order of small up and down big. The particle size from top to bottom is 1-8mm, and the bulk density is 1480-2800kg / m 3 . Johnson net 4-5 adopts high temperature resistant sieve plate type Johnson net 4-5, and its sieve bar interval is 3mm. The grid plates 4-6 are made of high temperature resistant materials, and the grid interval is 20mm. Other components and their connections are the same as in Embodiment 1.

[0038] The method for dedusting the raw coal gas with the above-mentioned device is the same as in Example 1.

Embodiment 3

[0040] In this embodiment, the filter layer 4-3 adopts pumice as the filter material, and the thickness of the filter material is 200mm. 210~360kg / m 3 . The current-stabilizing layer 4-4 is arranged with metal balls with a thickness of 300mm. The metal balls are distributed in the order of large bottom and small top. 3 . Johnson net 4-5 adopts high temperature resistant sieve plate type Johnson net 4-5, and its sieve bar spacing is 7mm. The grid plates 4-6 are made of high temperature resistant materials, and the grid interval is 80mm. Other components and their connections are the same as in Embodiment 1. The method for dedusting the raw coal gas with the above-mentioned device is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com