Method for controlling bed material balance of breeches-leg shaped CFBC (circulating fluidized bed boiler)

A technology of circulating fluidized bed and control method, applied in fluidized bed combustion equipment, combustion method, fuel burning in molten state, etc., can solve the problem that material imbalance cannot be corrected in time, operator skills are highly dependent, and Corresponding improvement and other issues to achieve the effect of improving safety and energy saving, shortening the time of adverse effects, and reducing the energy consumption of the actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

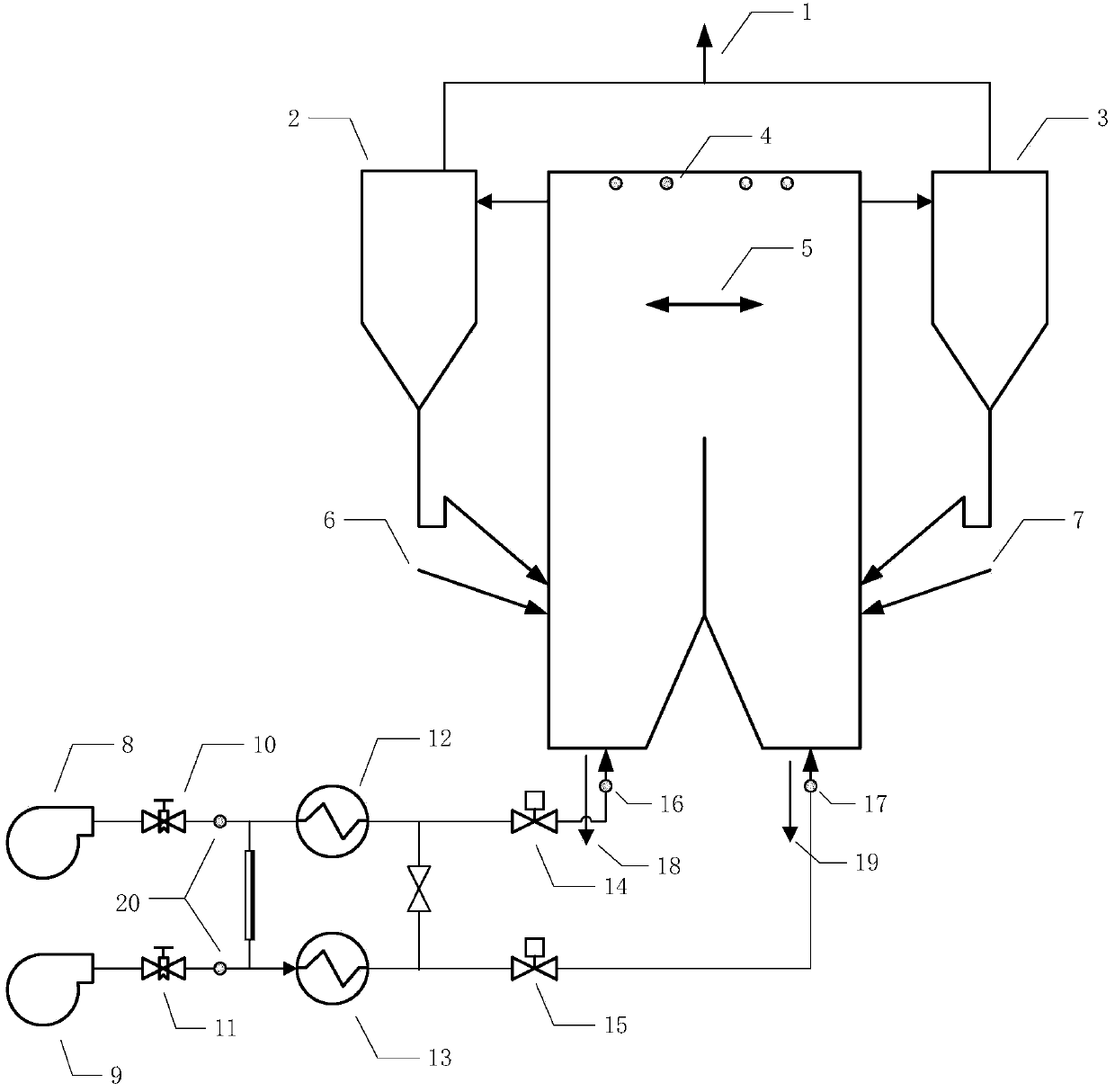

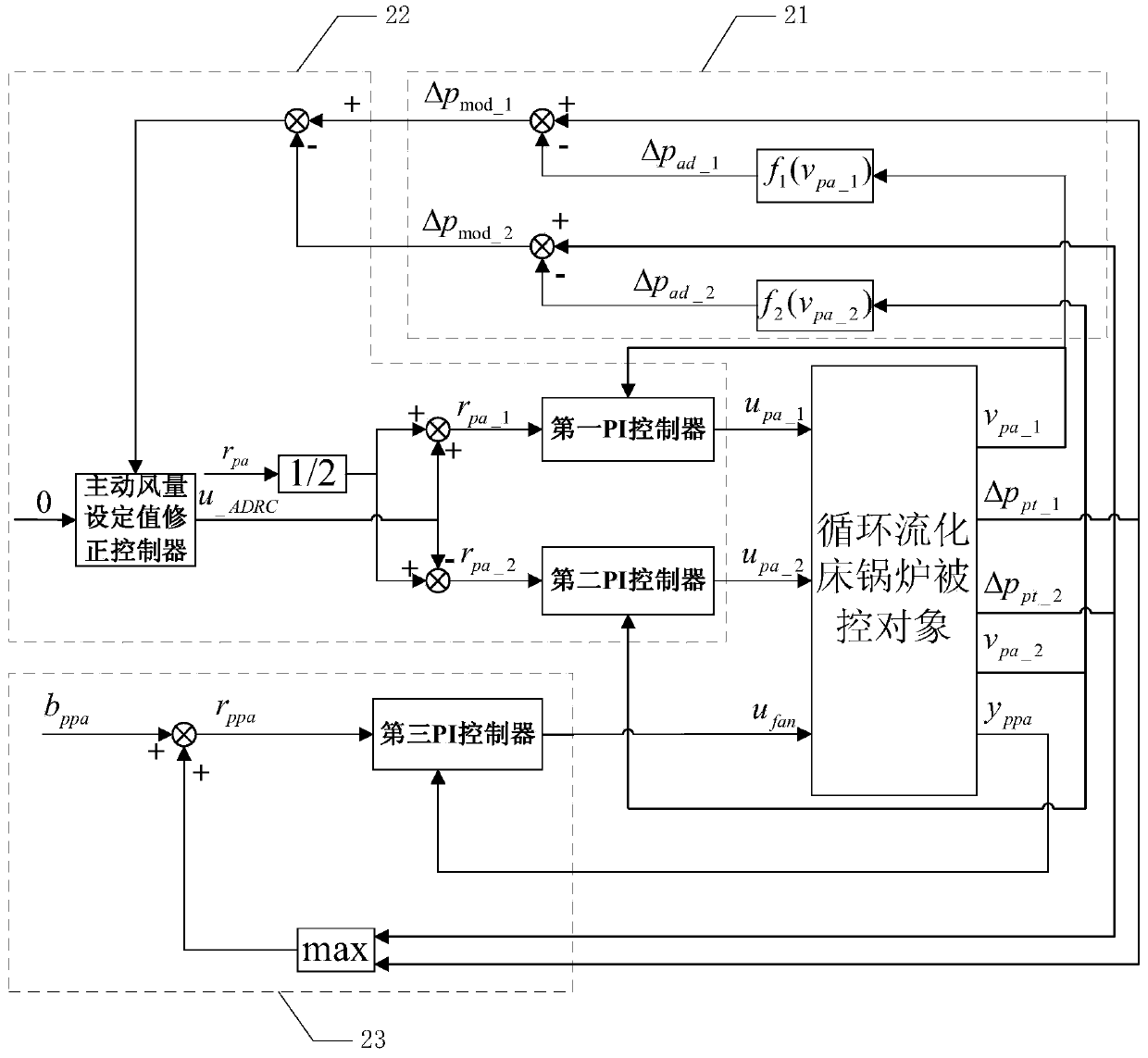

[0023] A kind of underpants leg type circulating fluidized bed boiler bed material balance control method that the present invention proposes is described in detail below in conjunction with accompanying drawing:

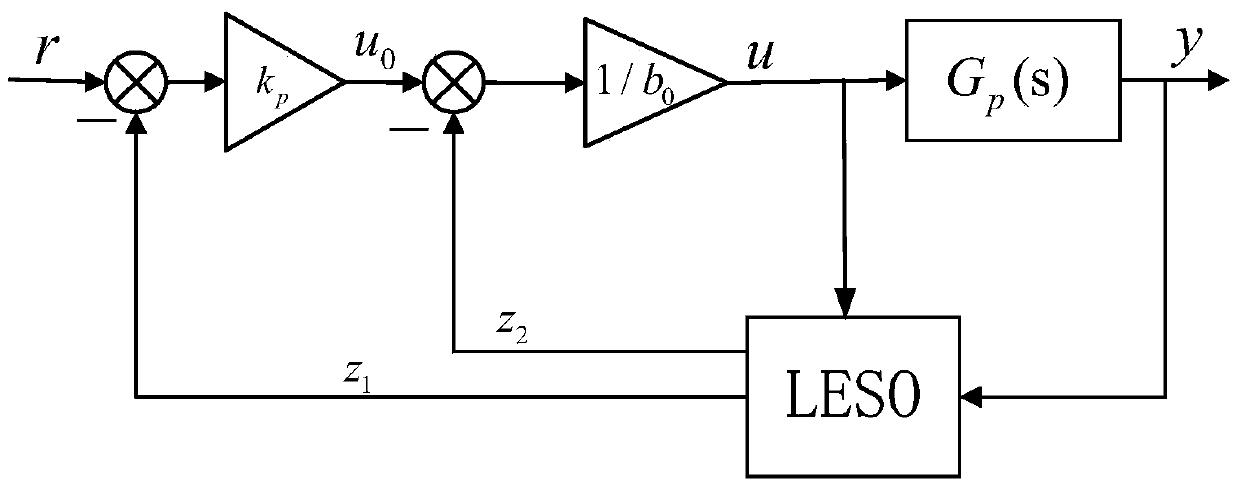

[0024] The primary air volume control system designed by the present invention generally needs to control the opening of 4 adjustable doors. In the process of realization, it mainly includes such as figure 1The guide vanes of the two primary fans on both sides shown in the middle, and the primary hot air dampers of the air duct burners on both sides. Among them, the fans on both sides supply the primary hot air on both sides at the same time. Before passing through the primary air control door, the two channels are connected, so the opening of the guide vanes of the primary fans on both sides is controlled by the same PI controller, that is, the third PI controller ; The left and right primary air control doors need to control the primary air volume entering both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com