Sintering ore with uniform grain size and production method thereof

A sintered and uniform technology, applied in the field of iron and steel metallurgy, can solve the problems of poor reduction capacity of blast furnace, high solid fuel consumption, and large proportion of small and large particle sizes, so as to reduce the consumption of solid fuel, facilitate strengthening smelting, and improve particle size. level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S1. Batching process: Mix the following raw materials by mass fraction: 18% western powder, 24% PB powder, 12% goldbuba powder, 5% Brazilian coarse powder, 6% FMG mixed powder, 15% returned ore, dolomite powder 5.0%, white ash 6.5%, limestone powder 4%, coal powder 2.3%, coke powder 2.2%;

[0029] b. Adding water and mixing process: adding water to the mixture in S1 and controlling the moisture content of the mixture at 7.1-7.5%;

[0030] c. Thermal parameter control: spread the mixed material on the sintering machine, control the ignition temperature of the sintering machine at 1050±50°C, control the thickness of the sintering material layer at 760-780mm, and control the end point temperature at 390±30°C.

[0031] Preferably, the temperature of the waste gas in the large flue is controlled at 120-140° C., and the speed of the sintering machine is controlled at 1.8-2.0 m / min.

Embodiment 2

[0033] S1. Batching process: mix the following raw materials by mass fraction: super special powder 15%, Newman powder 20%, Mike powder 10%, Brazilian mixed powder 7%, FMG mixed powder 14.6%, returned ore 15%, dolomite powder 4.0 %, white ash 7%, limestone powder 3%, coal powder 2.2%, coke powder 2.2%;

[0034] b. Adding water and mixing process: adding water to the mixture in S1 and controlling the moisture content of the mixture at 7.1-7.5%;

[0035] c. Thermal parameter control: spread the mixed material on the sintering machine, control the ignition temperature of the sintering machine at 1050±50°C, control the thickness of the sintering material layer at 760-780mm, and control the end point temperature at 390±30°C.

[0036] Preferably, the temperature of the waste gas in the large flue is controlled at 120-140° C., and the speed of the sintering machine is controlled at 1.8-2.0 m / min.

Embodiment 3

[0038] S1, batching process: mix the following raw materials by mass fraction: Luobo river powder 6.2%, PB powder 25%, Yangdi powder 15%, Indian powder 5%, Brazilian mixed powder 15%, returned ore 15%, dolomite powder 5.0%, white ash 7.5%, limestone powder 2%, coal powder 2.2%, coke powder 2.1%;

[0039] b. Adding water and mixing process: adding water to the mixture in S1 and controlling the moisture content of the mixture at 7.1-7.5%;

[0040] c. Thermal parameter control: spread the mixed material on the sintering machine, control the ignition temperature of the sintering machine at 1050±50°C, control the thickness of the sintering material layer at 760-780mm, and control the end point temperature at 390±30°C.

[0041]Preferably, the temperature of the waste gas in the large flue is controlled at 120-140° C., and the speed of the sintering machine is controlled at 1.8-2.0 m / min.

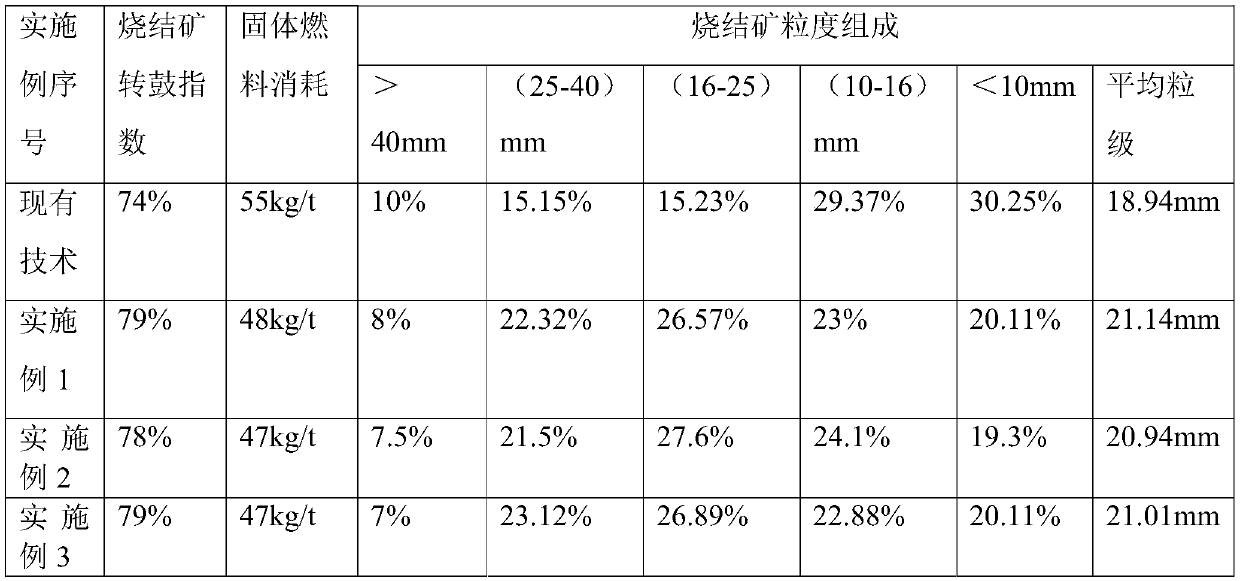

[0042] After inspection, the above 3 embodiments of the present invention and the various dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com