A kind of compound auxiliary agent and its preparation method and application

A technology of composite additives and organic binders is applied in the preparation of composite additives, and the application field of vanadium titanomagnetite production sinter, which can solve the problems of low utilization coefficient, low vertical sintering speed, and small liquid phase amount. , to achieve the effect of promoting the formation of liquid phase, good economic benefits and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] According to a preferred embodiment of the present invention, mixing is carried out as follows:

[0021] (1) At a rate of 50-100r / min, the first mixing is 3-5min;

[0022] (2) Then under the speed of 200-300r / min, the second mixing 2-3min;

[0023] (3) Finally, at the speed of 50-100r / min, the first mixing is 3-5min.

[0024] According to the method of the present invention, preferably based on the total weight of raw materials after mixing, the consumption of active lime powder is 75-90% by weight, the consumption of organic binder is 5-20% by weight, and the consumption of mineralizer is 0-10% by weight %, the consumption of additives is 0-5% by weight, preferably the consumption of active lime powder is 78-89% by weight, the consumption of organic binder is 5-10% by weight, and the consumption of mineralizer is 5-8% by weight, The additive is used in an amount of 1-4% by weight.

[0025] According to the method of the present invention, the indicators of the activ...

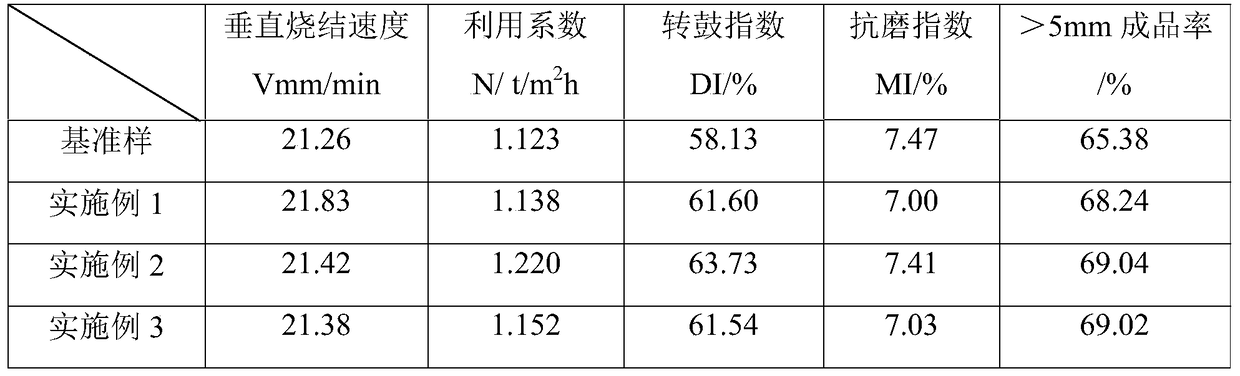

Embodiment 1

[0050] Containing 89wt% of active lime powder, 5wt% of organic binder, 5wt% of mineralizer, and 1wt% of additives were kneaded at a low speed of 50r / min for 3min on the mixer, and then kneaded at a high speed of 200r / min for 2min. Then mixed at a low speed of 50r / min for 3min to discharge the material, and the physical and chemical indicators of the obtained composite additives are shown in Table 1.

[0051] The active lime index is: 4.12wt% ignited reduction, 92.34wt% CaO content, 0.35wt% MgO content, SiO 2 The content is 0.13wt%, the proportion of particle size less than 0.088mm is 93wt%, and the activity is 385ml.

[0052] The index of the organic binder is: loss on ignition 24.50wt%, SiO 2 The content is 28.75wt%, Al 2 o 3 The content is 32.28wt%, the CaO content is 1.97wt%, the viscosity value is 32MPa.s, and the proportion of particle size less than 0.044mm is 94wt%.

[0053] The mineralizer is: boric acid, wherein the boric acid meets the corresponding index require...

Embodiment 2

[0056] Containing 85wt% of active lime powder, 8wt% of organic binder, 7wt% of mineralizer, and 2wt% of additives were kneaded at a low speed of 75r / min for 4min on the mixer, and then kneaded at a high speed of 250r / min for 3min. Then mixed at a low speed of 75r / min for 3min to discharge the material, and the physical and chemical indicators of the obtained composite additives are shown in Table 1.

[0057] The active lime index is: ignited reduction 5.26wt%, CaO content is 92.61wt%, MgO content is 0.23wt%, SiO 2 The content is 0.16wt%, the proportion of particle size less than 0.088mm is 94wt%, and the activity is 380ml.

[0058] The index of the organic binder is: loss on ignition 24.50wt%, SiO 2 The content is 28.75wt%, Al 2 o 3 The content is 32.28wt%, the CaO content is 1.97wt%, the viscosity value is 32MPa.s, and the ratio of less than 0.044mm is 94wt%.

[0059] The mineralizer is: a mixture of boron iron concentrate and boric acid, the mixing ratio is 1:1;

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com