Additive for improving sinter reducibility, high-reducibility sinter and preparation method thereof

A technology for sintering ore and additives, applied in the field of iron and steel metallurgy sintering, can solve problems such as complex operation, and achieve the effects of simple process, strong operability, and solving complex operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

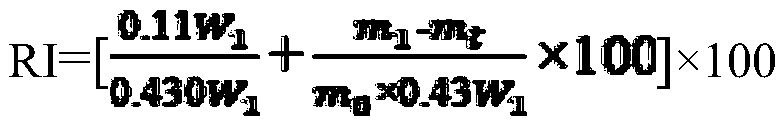

Image

Examples

preparation example Construction

[0025] The preparation of highly reducing sintered ore of the present invention comprises the following steps:

[0026] 1. Preparation of additives to improve the reducibility of sinter

[0027] Boron-containing compounds, hydrogen peroxide (H 2 o 2 ), permanganate and water are uniformly mixed to obtain the additive; wherein, in terms of mass percentage, the additive contains 0.05% to 5% of boron compounds, 0.1% to 10% of hydrogen peroxide (H 2 o 2 ), 0.03% to 3% permanganate, and the rest is water. The boron-containing compound is potassium tetraborate (K 2 B 4 o 7 ·5H 2 O) and sodium tetraborate (Na 2 B 4 o 7 10H 2 O) one or a mixture of two. Permanganate is potassium permanganate (KMnO 4 ) and sodium permanganate (NaMnO 4 ) or a mixture of both.

[0028] 2. Break the ordinary sinter obtained by sintering (ie the sinter described in the present invention), spray the above-mentioned additive on the surface of the sinter at 400-600°C, and when the additive full...

Embodiment 1

[0044] The preparation steps of the highly reducing sintered ore in this embodiment are:

[0045] 1) prepare additive, in this additive, by mass percent, comprise 0.05% potassium tetraborate, 0.1% hydrogen peroxide, 0.03% potassium permanganate, and the water of remaining weight, potassium tetraborate, hydrogen peroxide, Mix potassium permanganate and water evenly.

[0046] 2) After the experimental raw materials obtained by sintering are crushed, they are cooled in a ring cooler, and the middle diameter speed of the trolley is reduced to 0.6m / min. When the surface temperature of the sintered ore reaches 400°C, the additive is sprayed on the surface of the sintered ore, 0.5kg of the additive is sprayed per ton of sintered ore, and the highly reducing sintered ore is obtained after cooling to room temperature.

Embodiment 2

[0048] The preparation steps of the highly reducing sintered ore in this embodiment are:

[0049] 1) prepare additive, in this additive, by mass percent, comprise 0.25% potassium tetraborate, 0.5% hydrogen peroxide, 0.15% potassium permanganate, and the water of remaining weight, potassium tetraborate, hydrogen peroxide, Mix potassium permanganate and water evenly.

[0050] 2) After crushing the experimental raw materials obtained by sintering, cool them in the ring cooler, reduce the speed of the middle diameter of the trolley to 0.5m / min, and adjust the blast volume of the first two stages of the ring cooler to be 1.25 times of the conventional blast volume. When the surface temperature of the sintered ore reaches 450°C, the additive is sprayed on the surface of the sintered ore, and 1.0kg of the additive is sprayed per ton of sintered ore, and the sintered ore with high reducing property is obtained after cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com