A kind of iron ore microwave sintering method

A technology of microwave sintering and iron ore, applied in the field of sintering technology, can solve the problems of large investment, failure to fully utilize by-products, and limited decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

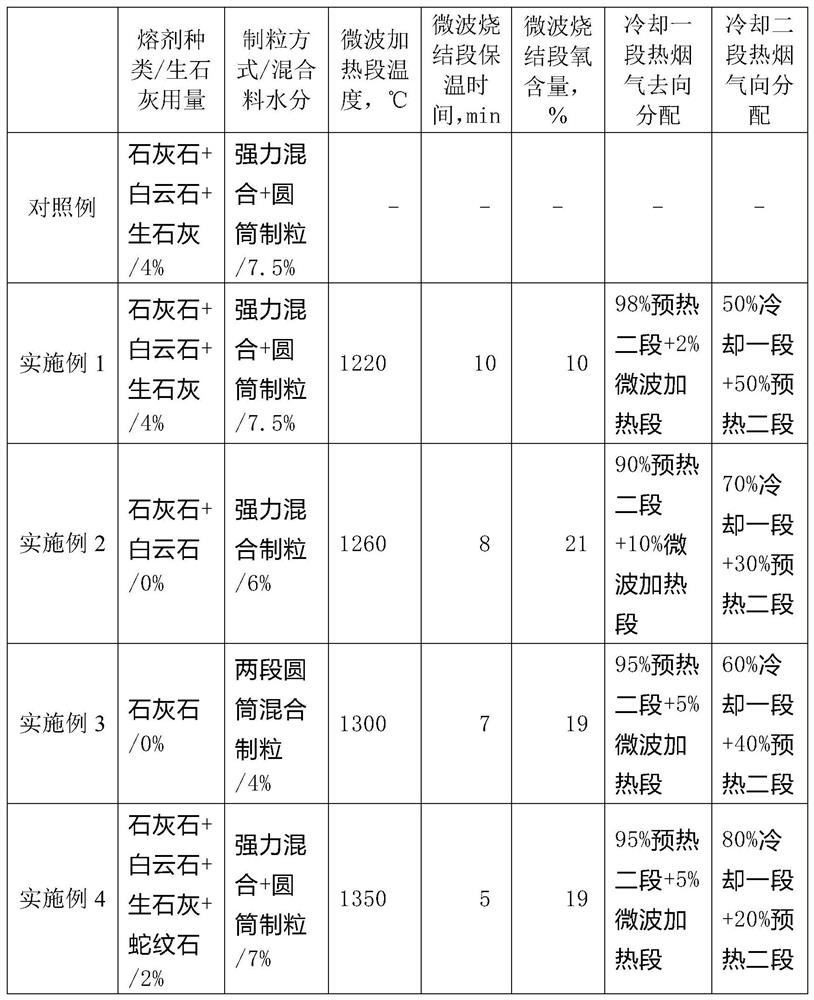

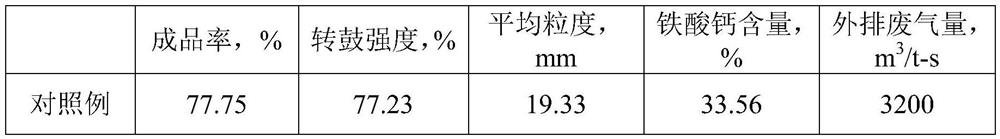

Examples

Embodiment Construction

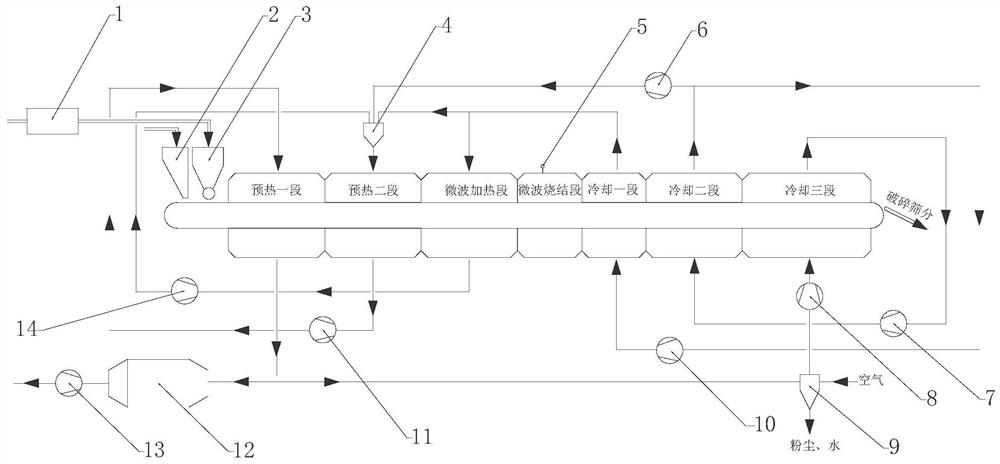

[0032] please see figure 1 Shown, iron ore microwave sintering method of the present invention specifically comprises the following steps:

[0033] 1) Batch iron ore, flux, returned ore and iron-containing solid waste according to the set sinter composition, and transport them to the mixing silo 3 after being mixed and granulated by the mixing and granulating device 1;

[0034] 2) Then use the round roller feeding method to directly load the mixture in the mixing bin into the sintering trolley on which the 5-10mm bottom material has been laid;

[0035] 3) The sintering trolley filled with the mixture passes through the first stage of preheating, the second stage of preheating, the microwave heating stage, the microwave sintering stage, the first stage of cooling, the second stage of cooling and the third stage of cooling according to the set moving speed, so that the mixture Ore formation after preheating, heating, sintering and cooling;

[0036] 4) After crushing and screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com