Double-layer sintering method and sintering device

A sintering method and technology of a sintering device, applied in the field of sintering, can solve problems such as poor sinter strength and insufficient sintering oxygen content, and achieve the effects of improving production capacity, improving homogeneity, and solving insufficient oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

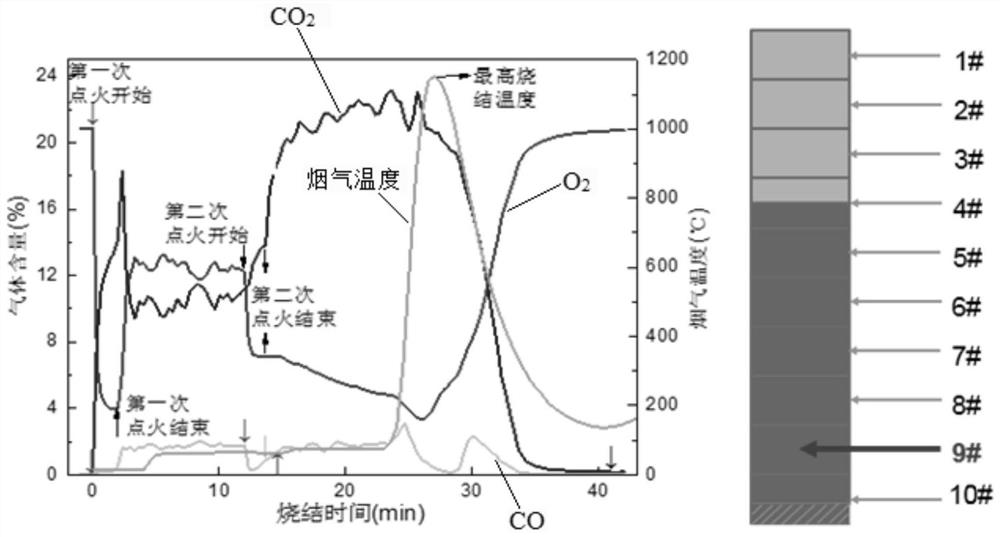

[0061] According to a first embodiment of the present invention, a double layer sintering method is provided.

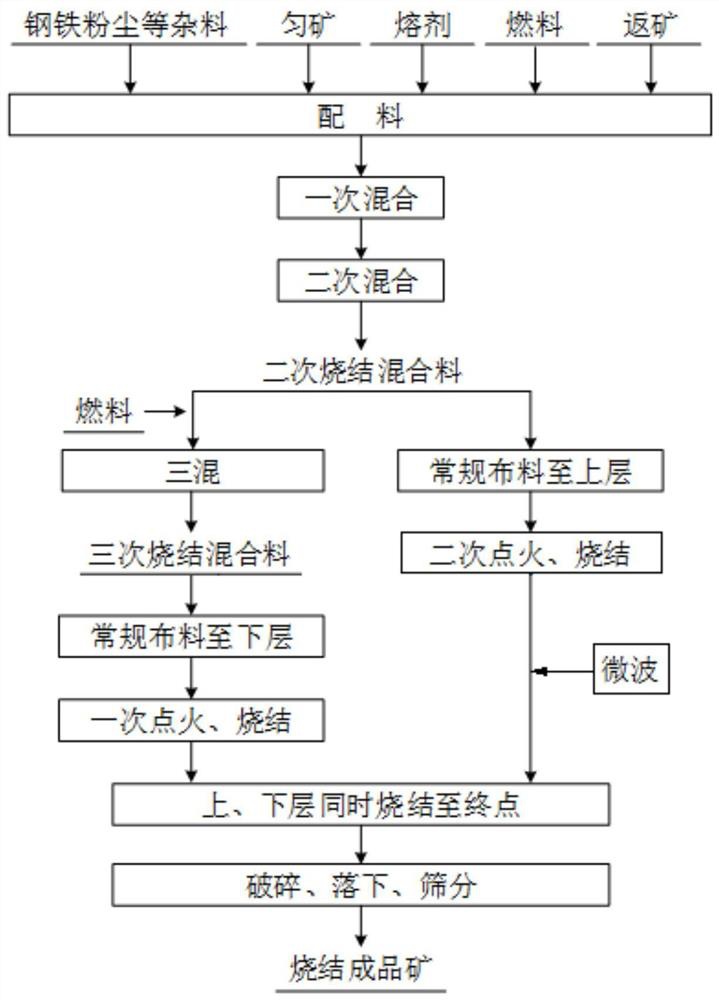

[0062] A kind of double-layer sintering method, this method comprises the following steps:

[0063] 1) Batching and primary mixing: batching iron-containing raw materials, flux and fuel, and preliminarily mixing the prepared materials to obtain a preliminary sintering mixture;

[0064] 2) Remixing: adding fuel to the sintered primary mixture for remixing to obtain a sintered remixed mixture;

[0065] 3) Ignite the primary fabric: Lay the base material L0 on the sintering trolley 1, lay the sintered remixed mixture on the base material to obtain the first fabric layer L1, and then perform primary ignition and sintering on the first fabric layer L1;

[0066] 4) Secondary fabric ignition: Lay sintered primary mixture on the first fabric layer L1 to obtain the second fabric layer L2, then perform secondary ignition and sintering on the second fabric layer L2, and provid...

Embodiment 1

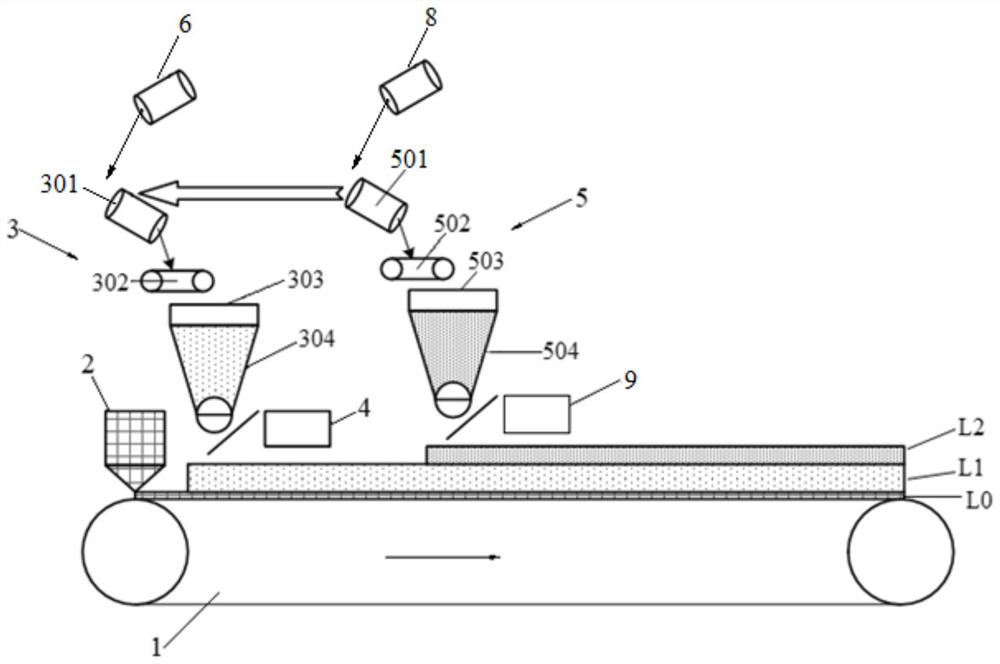

[0089] Such as image 3 As shown, a double-layer sintering device includes a sintering trolley 1 . Along the running direction of the sintering trolley 1 , the device also includes a bottom bunker 2 , a primary distribution device 3 , a primary ignition device 4 , and a secondary distribution device 5 arranged sequentially above the sintering trolley 1 .

[0090] Wherein, the primary distribution device 3 is located downstream of the bottom bunker 2 , and the primary distribution device 3 includes a tertiary cylinder mixer 301 , a first belt conveyor 302 , a first shuttle distributor 303 , and a first mixing bin 304 . The first adhesive tape machine 302 is arranged below the discharge port of the tertiary cylinder mixer 301 . The first shuttle distributor 303 is arranged below the first tape machine 302 . The first mixing bin 304 is arranged below the first shuttle distributor 303 and above the sintering trolley 1 . The primary ignition device 4 is located downstream of the...

Embodiment 2

[0093] Repeat Example 1, except that the device further includes a primary cylinder mixer 8 , and the discharge port of the primary cylinder mixer 8 is connected to the feed port of the secondary cylinder mixer 501 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com