High titan type high alkalinity sinter and method for preparing same

A sintered ore, high-titanium type technology, applied in the field of metallurgy, can solve the problems of failing to meet the sintering requirements of Panzhihua vanadium-titanium magnetite concentrate, sintering ore failing to meet smelting quality requirements, and poor metallurgical properties of vanadium-titanium sintering ore, etc., to achieve easy operation , Improve the strength and improve the effect of metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

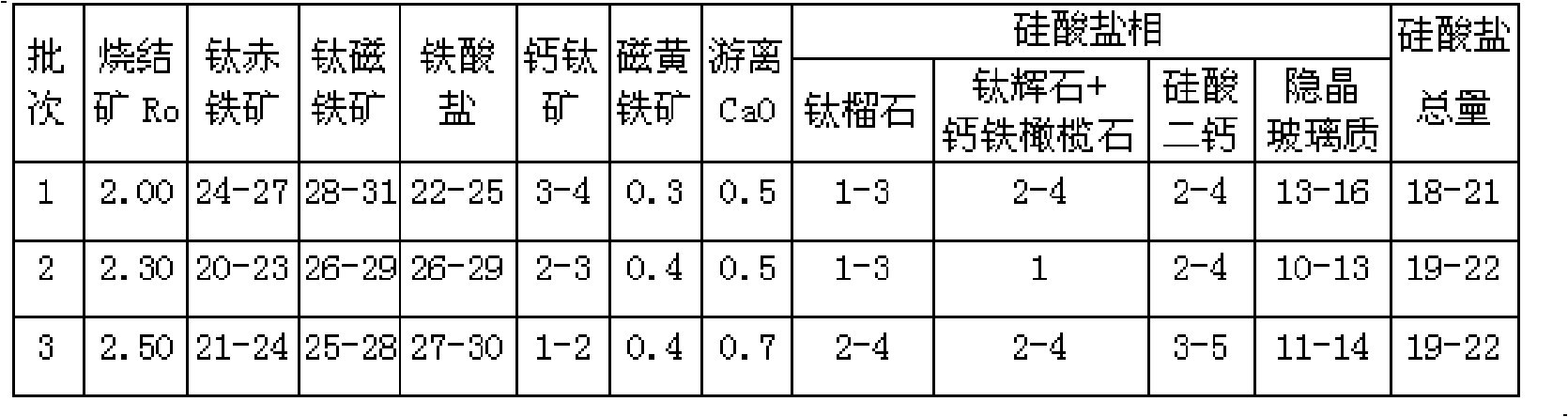

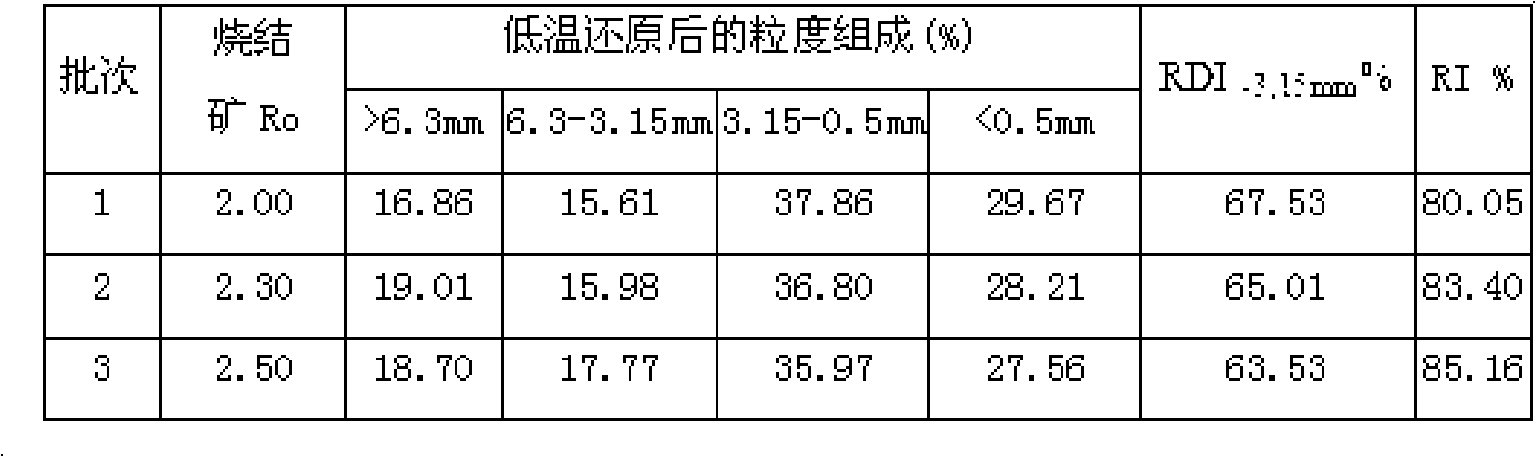

Examples

preparation example Construction

[0013] The sinter preparation method of the present invention comprises the following steps: A, batching, B, mixing, C, distributing, D, igniting, sintering, E, thermal crushing, F, thermal screening, G, cooling, H, screening. After sieving, the blast furnace can be smelted. Specifically, the mixing in step B can be mixed twice; the sieving in step H can be sintered sieving and ditch sieving.

[0014] The raw material for sintering is mainly vanadium-titanium magnetite concentrate produced in Panzhihua, the ratio can be as high as 50%-80%, and a small amount of ordinary rich ore powder, flux, fuel, and externally mixed ore return are used for sintering, and the single concentrate can also be sintered. sintering. The composition content (by weight) of the vanadium-titanium magnetite concentrate contains: TFe 52-55%, FeO 29-32%, SiO 2 3-4%, CaO 1.5-2.0%, MgO2.0-2.5%, Al 2 o 3 3.0-4.5%, V 2 o 5 0.5-0.6%, TiO 2 13-15%, S 0.4-0.6%; and the particle size is coarse, the co...

Embodiment 1

[0044] Raw materials use the vanadium-titanium magnetite concentrate in Table 1, in terms of weight percentage: 54% of vanadium-titanium magnetite concentrate, 26% of ordinary fine ore (11% of Australian fine ore + 12% of domestic high-grade fine ore + domestic medium-grade fine ore 3%), limestone 5.5%, quicklime 7.0%, coke powder 4.6% (or anthracite 6.0%), ore return 40%.

[0045] The thickness of the material layer is 565mm, the machine speed is 1.55m / min, the ignition temperature is 1087°C, the sintering temperature is 1350°C, the exhaust gas temperature of the main pipe is 113°C, the sintering end point temperature is 280°C, and the sintering negative pressure is 12900Pa.

[0046] Increase the sinter basicity to 2.16, resulting in a technical effect of sintering machine utilization factor of 1.322t / m 2 ·h, the ISO drum index (>6.3mm%) is 69.95%, and the solid fuel consumption is 53.40kgce / t.

Embodiment 2

[0048] Raw materials use the vanadium-titanium magnetite concentrate in Table 1, in terms of weight percentage: 53% of vanadium-titanium magnetite concentrate, 27% of ordinary fine ore (12% of Australian fine ore + 12% of domestic high-grade fine ore + domestic medium-grade fine ore 3%), limestone 7.2%, quicklime 7.0%, coke powder 4.5% (or anthracite 6.0%), ore return 35%.

[0049] The thickness of the material layer is 567mm, the machine speed is 1.53m / min, the ignition temperature is 1083°C, the sintering temperature is 1350°C, the exhaust gas temperature of the main pipe is 112°C, the sintering end point temperature is 285°C, and the sintering negative pressure is 12830Pa.

[0050] Raise the sinter basicity to 2.45, resulting in a technical effect of sintering machine utilization factor of 1.404t / m 2 ·h, the ISO drum index (>6.3mm%) is 71.55%, and the solid fuel consumption is 48.72kgce / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com