Method of accurately controlling consumable electrode remainder in electroslag remelting

A consumable electrode and electroslag remelting technology, which is applied in the field of electroslag remelting technology, can solve the problems of poor adaptability and controllability, difficult operation and control, and large errors, so as to achieve strong controllability and improve utilization The effect of high efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

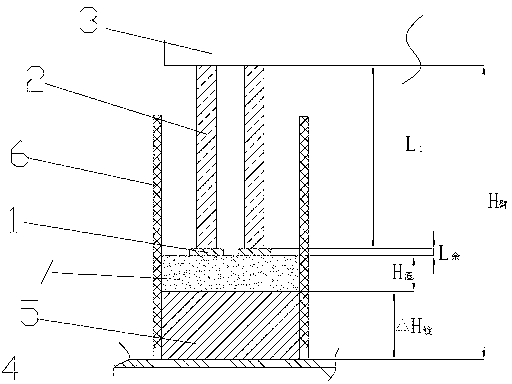

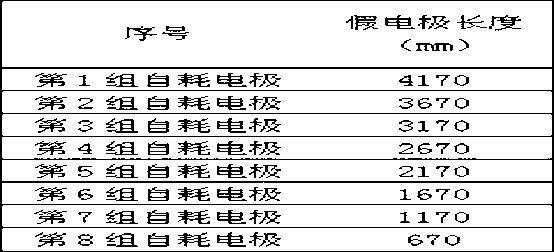

[0025] Using 24 consumable electrodes of φ480mm to produce 80t electroslag ingot 5 (00Cr) in three-phase electroslag furnace 6 17 Ni 12 Mo 2 N), the increased height ΔH of the electroslag ingot 5 when each group of consumable electrodes is melted until the transverse arm 3 is at the lower limit 锭 500mm, slag thickness H 渣 300 mm, H 臂 In order that the vertical distance from the cross arm 3 to the bottom plate 4 is 5000mm when the cross arm 3 is in the lower limit position, the length of the remaining end 1 of the consumable electrode of each group of consumable electrodes is designed to be 30mm, so it is fixed in the first group of consumable electrodes. Length on the dummy electrode 2 according to L 1 = H 臂 -L 余 -△H 锭 -H渣 available, L 1 = 4170mm, the length of dummy electrode 2 set on the second group of consumable electrodes is according to L 2 = L 1 -△H 锭 available, L 2 = 3670 mm, the length of dummy electrode 2 set on the third group of consumable electrodes ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com